UV(ultraviolet) metal decorating offset print ink

An offset printing ink and iron printing technology, applied in inks, household appliances, applications, etc., can solve the problems of low production efficiency, difficulty in increasing the printing speed of the printing machine, high energy consumption, etc., and achieve good ink film toughness, bright colors, and dots clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

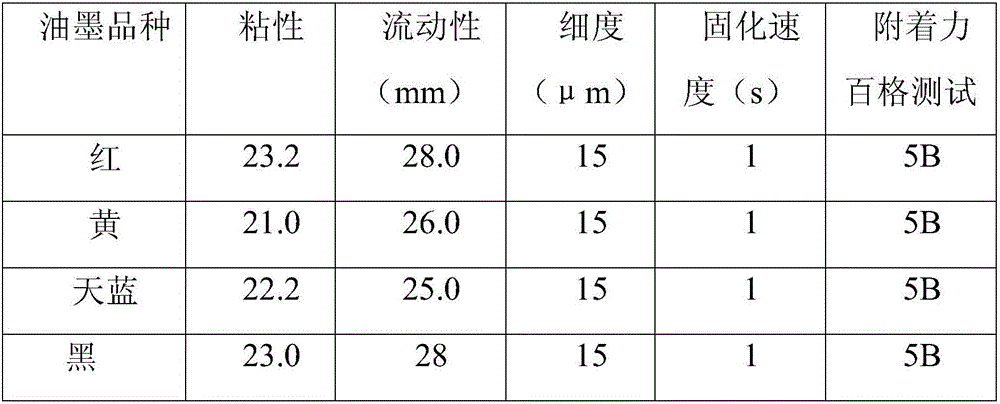

Examples

Embodiment 1

[0043] A UV offset printing ink for iron printing, the components and weight percentages of each material are as follows: 60-69 resin, 1.9-10.4 monomer activity, 4-4.5 talcum powder, 8-13 initiator, and 0.1 auxiliary agent , the color pigment is 10.4-17.3.

Embodiment 2

[0045] A kind of UV offset printing ink for iron printing, each material component and weight percentage are: polyester acrylic resin is 19, special acrylic resin is 41-50, talcum powder is 4-4.5, SR9020 is 1.9-10.4, photoinitiator 907 5-6, photoinitiator ITX is 2-3, photoinitiator BDK is 1, photoinitiator 369 is 0-3, 510 additive is 0.1, color pigment is 10.4-17.3.

Embodiment 3

[0047] A kind of UV offset printing ink for iron printing, each material component and weight percentage are: polyester acrylic resin is 19, special acrylic resin is 41-50, SR9020 is 1.9-10.4, talcum powder is 4-4.5, photoinitiator 907 5-6, photoinitiator ITX is 2-3, photoinitiator BDK is 1, photoinitiator 369 is 0-3, 510 additive is 0.1, magenta is 10.4-17.3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com