Cold in-plant recycling mixing device and method for asphalt mixtures

A technology of asphalt mixture and cold recycling, which is applied in the direction of roads, road repairs, roads, etc., can solve the problems of affecting the uniformity of the mixture, discounting the use performance, and failure to form, and achieves compact structure, high use performance, and land occupation. The effect of less area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The following combination Attached picture Embodiments of the present invention are described in detail, but the present invention can be according to claim A number of different ways of qualifying and covering are implemented.

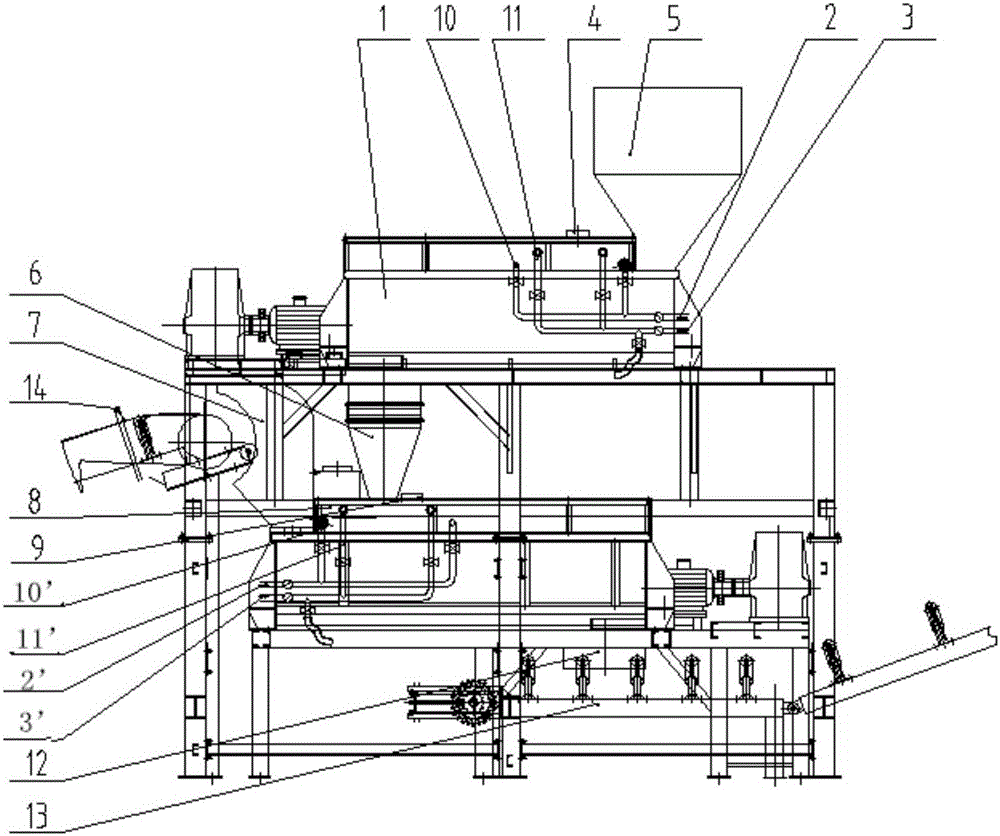

[0049] refer to icon 1,

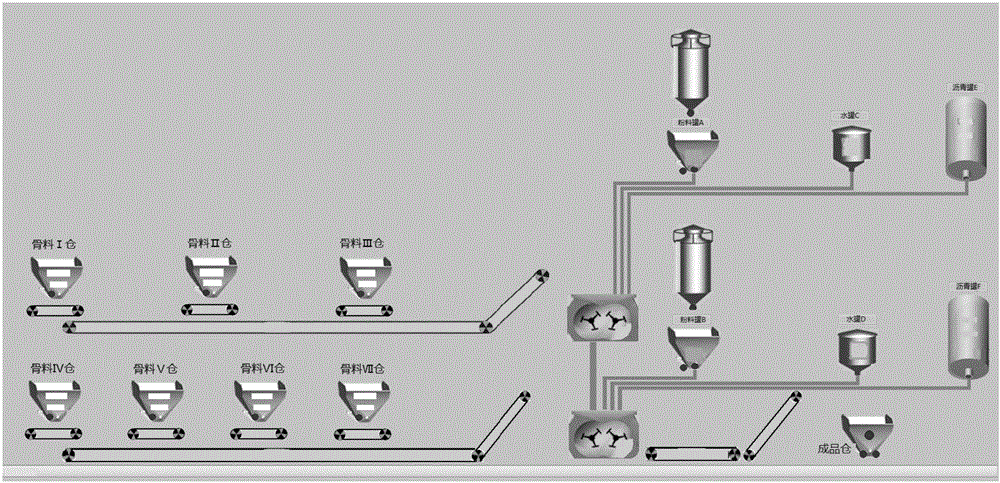

[0050] A double-layer multi-step mixing factory-mixed cold recycled asphalt mixture mixing equipment, mainly composed of a primary mixing tank 1, a secondary mixing tank 8, a flexible connection device 6, multiple aggregate hoppers for old aggregates and new aggregates, Two powder silos, first-level belt conveying device, first-level mixing tank feed hopper 5, first-level mixing tank water supply device 2, first-level mixing tank emulsified asphalt supply device 3, second-level belt conveying device, and second-level mixing tank Feeding hopper 7, primary mixing tank water supply pipe 10, primary mixing tank emulsified asphalt adding pipe 11, secondary powder adding device 9, finished product belt 13, secondary mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com