A safe construction technology of tunnel grouting curtain outside drain hole

A grouting curtain and safety technology, applied in safety devices, drilling equipment and methods, drainage and other directions to achieve smooth drainage, reduce seepage damage, and avoid scouring damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

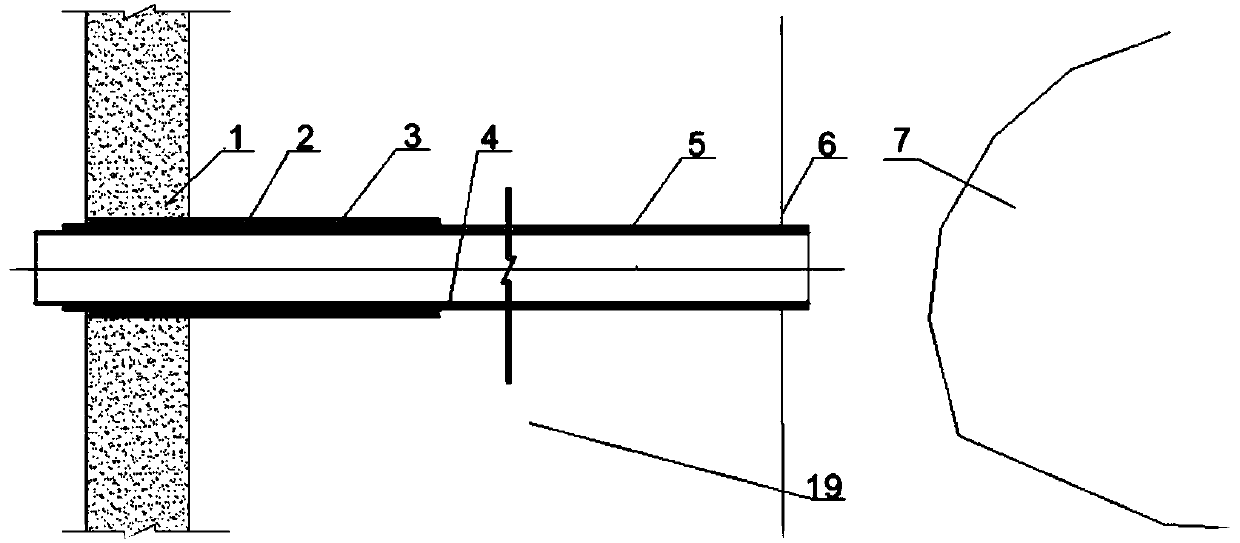

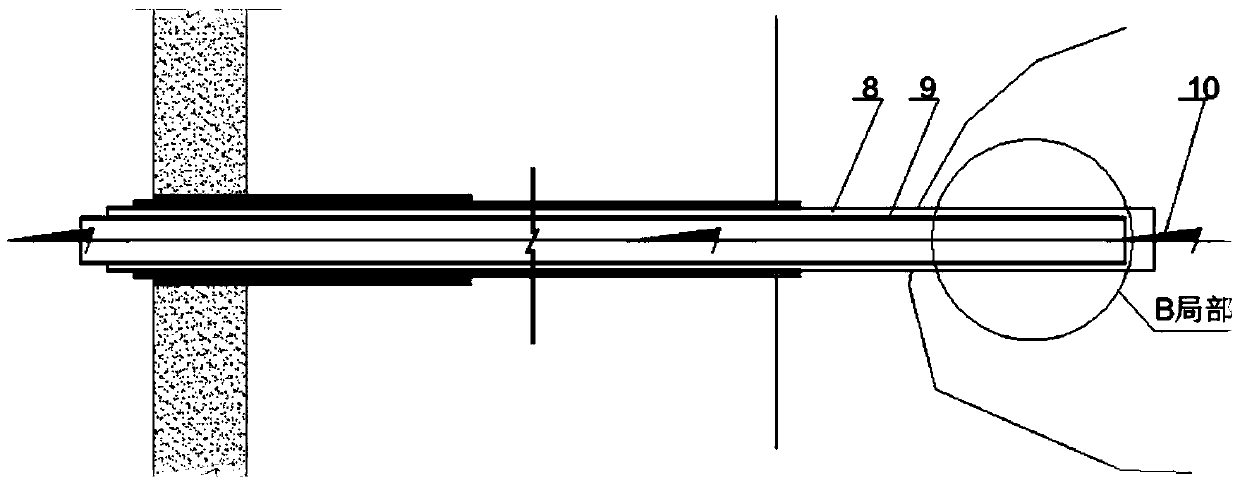

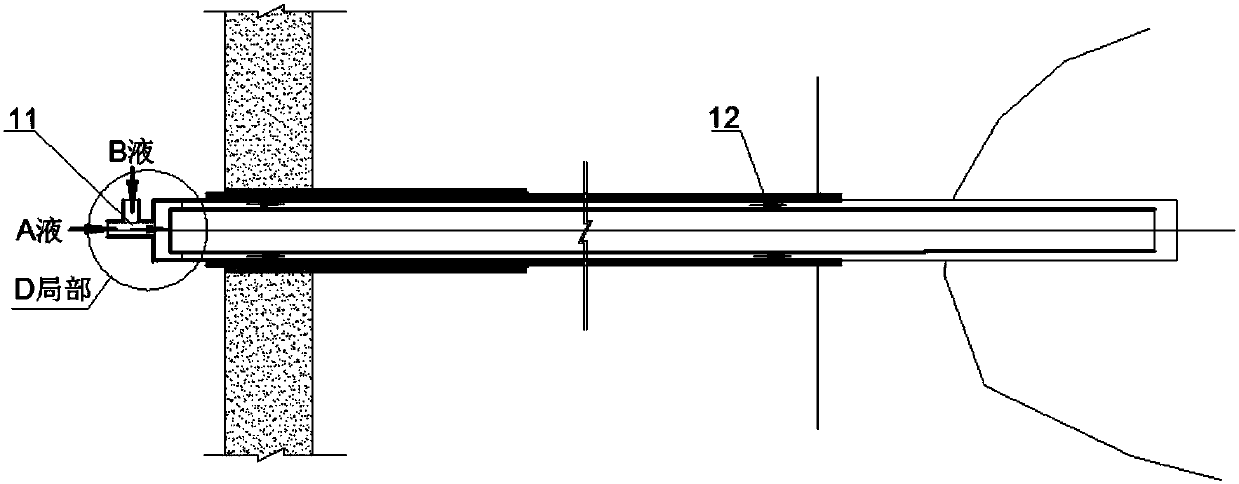

[0038] The present invention will be described in detail below in conjunction with accompanying drawing: the composition part of tunnel grouting curtain outer drain hole comprises: first grade sleeve pipe 3, second grade sleeve pipe 4 and drain sleeve pipe 9, grout stop wall 1, the first First-level casing sealing body 2, second-level casing sealing body 5, drainage casing sealing body 14, concentrated water-rich area 7 outside the curtain, grouting slurry for sealing casings at all levels and corresponding operating processes Wait. The figure shows the boundary 6 of the curtain circle reinforced by grouting, the drainage borehole 8 to expose the water-rich area, the direction 10 of diversion and drainage of groundwater in the concentrated water-rich area, and the flow direction 12 of the grout sealed by the drainage casing. The specific implementation steps are as follows:

[0039] In the first step, drilling holes are sequentially constructed in the grouting curtain through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com