Wireless remote real-time testing system for water injection well

A water injection well and remote technology, applied in the directions of measurement, wellbore/well components, production fluid, etc., can solve the problems of heavy workload, low test success rate, long time consumption, etc., to achieve convenient operation and use, strong practicability, significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

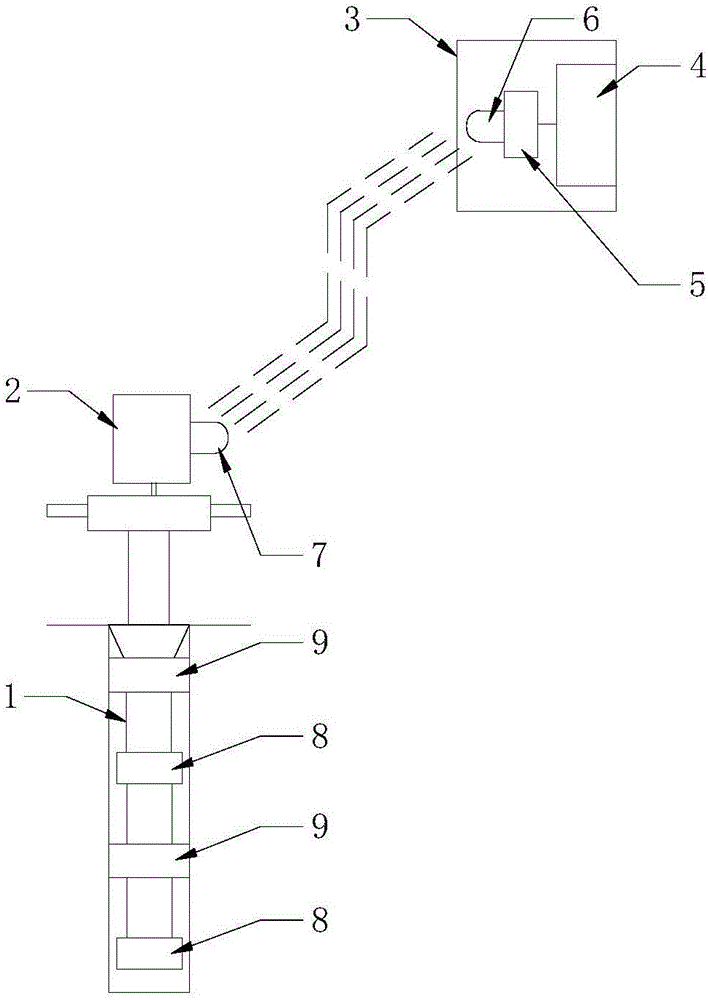

[0015] Embodiment 1: A wireless remote real-time commissioning system for water injection wells, including an intelligent downhole water distribution pipe string 1, a ground control unit 2, and a remote service unit 3. The remote service unit 3 includes a computer 4 and a server 5 connected to the computer 4. The server It is used to receive, store, and process relevant data, and the computer is used to display, store, and analyze data for user operation; the server 5 is connected with a first wireless transceiver 6, and the first wireless transceiver 6 communicates with the second wireless transceiver in a wireless manner. Transceiver 7 is connected, and the second wireless transceiver 7 is connected with the controller in the ground control part 2, and the first wireless transceiver cooperates with the second wireless transceiver to realize the transmission of data, and the transmission mode of this wireless remote data also can adopt GPRS data network single-channel transmis...

Embodiment 2

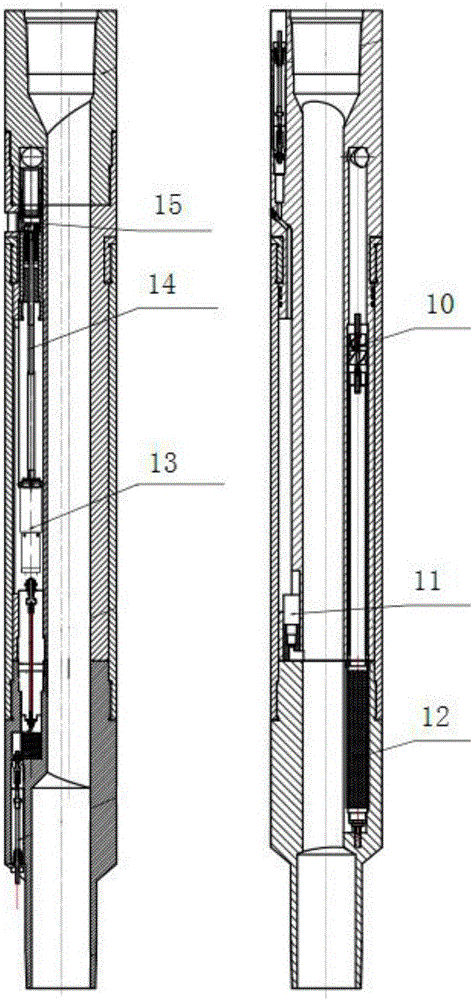

[0017] Embodiment 2: Further, the downhole intelligent water distributor is provided with a water outlet filter 12 and a motor 13, the motor 13 is connected with a regulator 14, the regulator 14 and the adjustable ceramic valve fixed in the downhole intelligent water distributor 8 15 connections.

Embodiment 3

[0018] Embodiment 3: Further, in order to improve the stability, firmness and durability of the cable, prevent and avoid the phenomenon of downhole production delay in the oil field, the cable between the downhole intelligent water distributor 8 and the controller is connected with a cable A fixed protection device, the cable fixed protection device includes a protection body 16 and fasteners connected to both ends of the protection body 16, the fasteners include a fixed shaft fixed on the protection body 16, and are respectively connected to the fixed shaft Two gussets 17, the free ends of the two gussets 17 are set to cooperate with each other in the tooth structure, and the tooth structure is vertically and vertically provided with a through hole, and the through hole is connected with a lock cylinder 18, and the lock cylinder 18 connects the two A pinch plate 17 is locked, and a lock or other locking methods can be set on the lock post 18.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com