High-strength confined concrete supporting system applicable to underground tunnel

A technology of confining concrete and concrete, which is applied in underground chambers, tunnels, earthwork drilling and mining, etc., can solve problems such as low construction and operation safety factors, increased risk of surrounding rock instability, and inability to effectively control surrounding rock, achieving high-strength Low ductility, low pressure resistance of concrete, and low overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

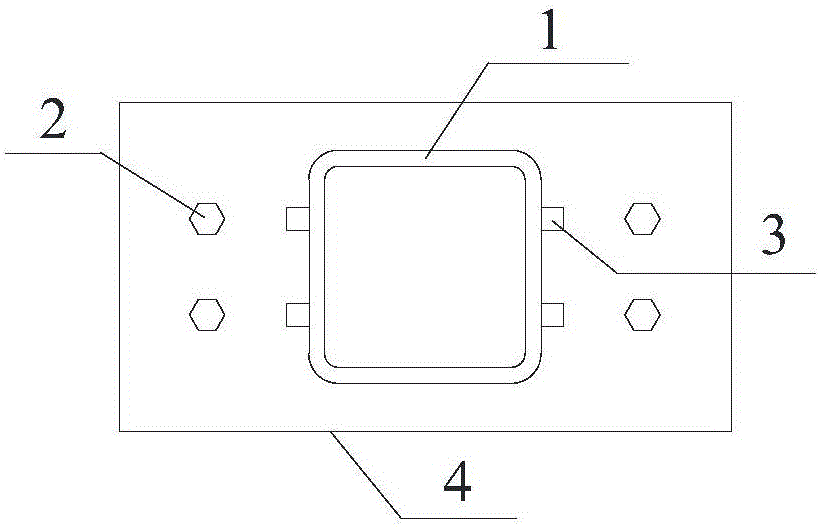

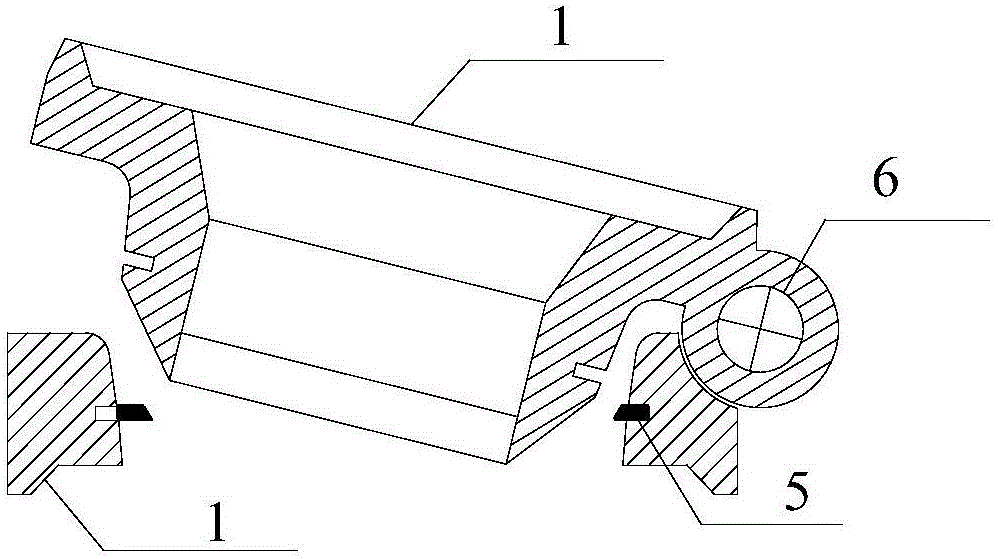

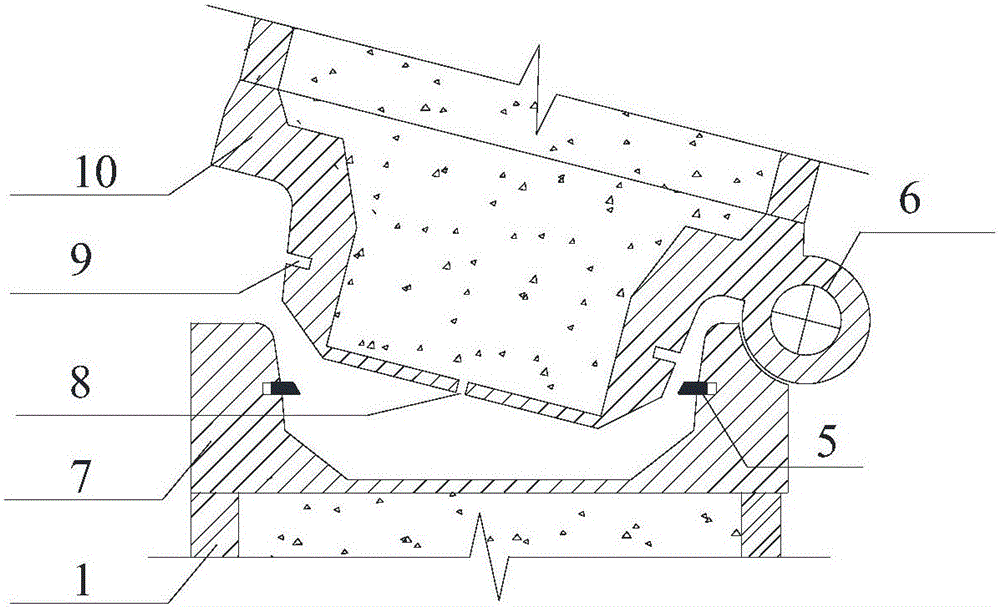

[0044] Such as Figure 10 , Figure 11 As shown, a restrained concrete arch support system suitable for large-section tunnels is mainly composed of a restrained concrete arch 1 for supporting the surrounding rock of the tunnel, steel mesh, longitudinal connecting bars and concrete spraying layer, etc., the restrained concrete arch The section of the frame 1 can be square or circular according to different conditions; the connection between each section of the arch 1 can be flanged or hinged, and different welding methods can be selected according to the shape of the section; the constrained concrete arch 1 Different filling and curing methods are selected for the filled concrete according to different construction methods; the welded ribs on the arch 1 strengthen the bond with the concrete; the steel mesh is arranged in two layers on the surrounding ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com