Turbocharger bearing sleeve and turbocharger

A turbocharger and bearing sleeve technology, applied in the direction of machines/engines, engine components, mechanical equipment, etc., can solve the problems of angular contact ceramic bearing spread, supercharger damage, turbine rotor shaft and angular contact bearing axial To solve the problem of large movement, to achieve the effect of reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

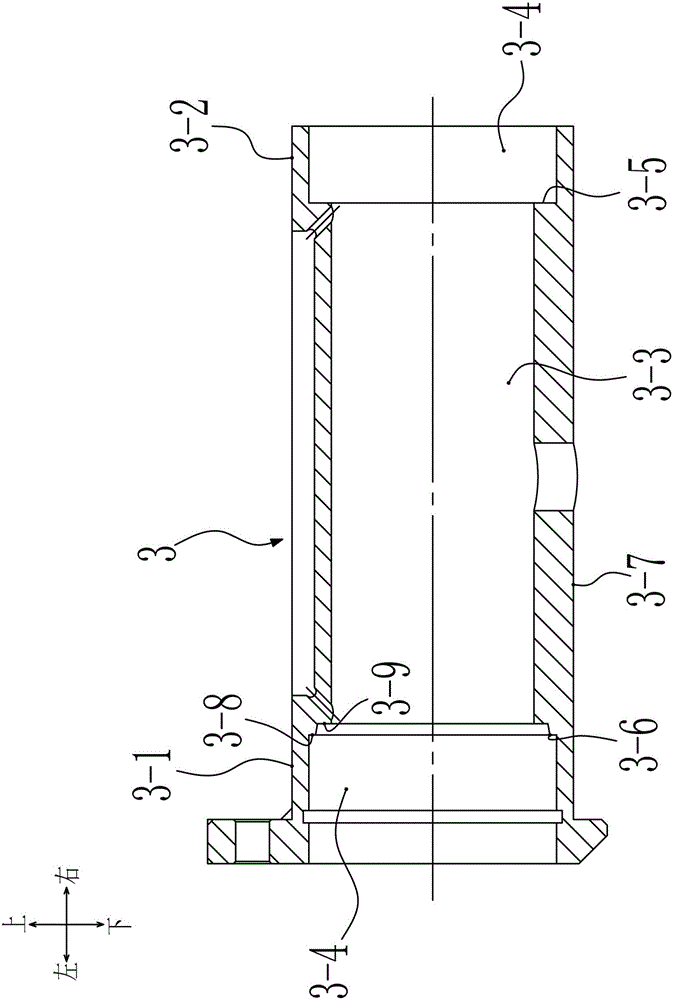

[0023] Such as figure 1 A turbocharger bearing sleeve is shown, which includes a straight sleeve body 3-7, the sleeve body 3-7 has a shaft hole 3-3 passing through along its axis, the sleeve The inner sides of the pressure end 3-1 and the scroll end 3-2 of the body 3-7 are provided with a bearing positioning hole 3-4 coaxial with the shaft hole 3-3, and the diameter of the bearing positioning hole 3-4 is larger than the The diameter of the shaft hole 3-3, the bottom of the bearing positioning hole 3-4 of the pressure end 3-1 is provided with an annular boss 3-6, and the diameter of the annular boss 3-6 is smaller than that of the bearing The diameter of the positioning hole 3-4 is larger than the diameter of the shaft hole 3-3. The shaft hole 3-3, the annular boss 3-6 and the bearing positioning hole 3-4 form a stepped hole. Specifically, on the side of the pressure end 3-1, the first shoulder 3-8 is formed between the outer end surface of the annular boss 3-6 and the inner ...

Embodiment 2

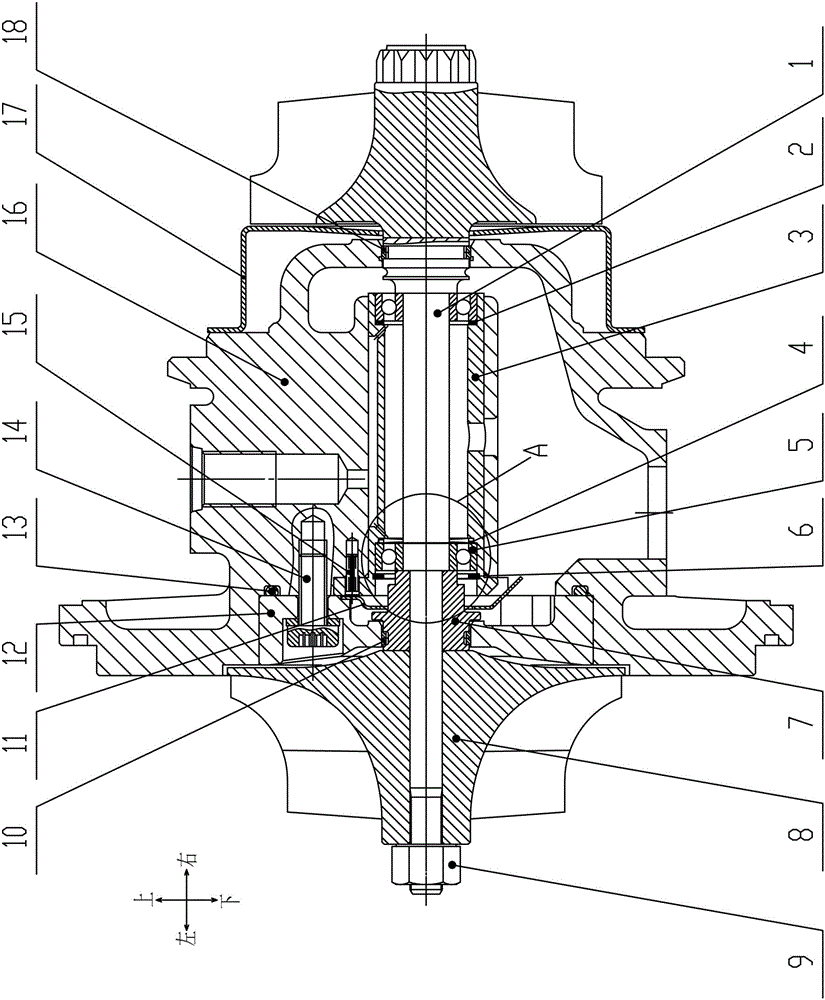

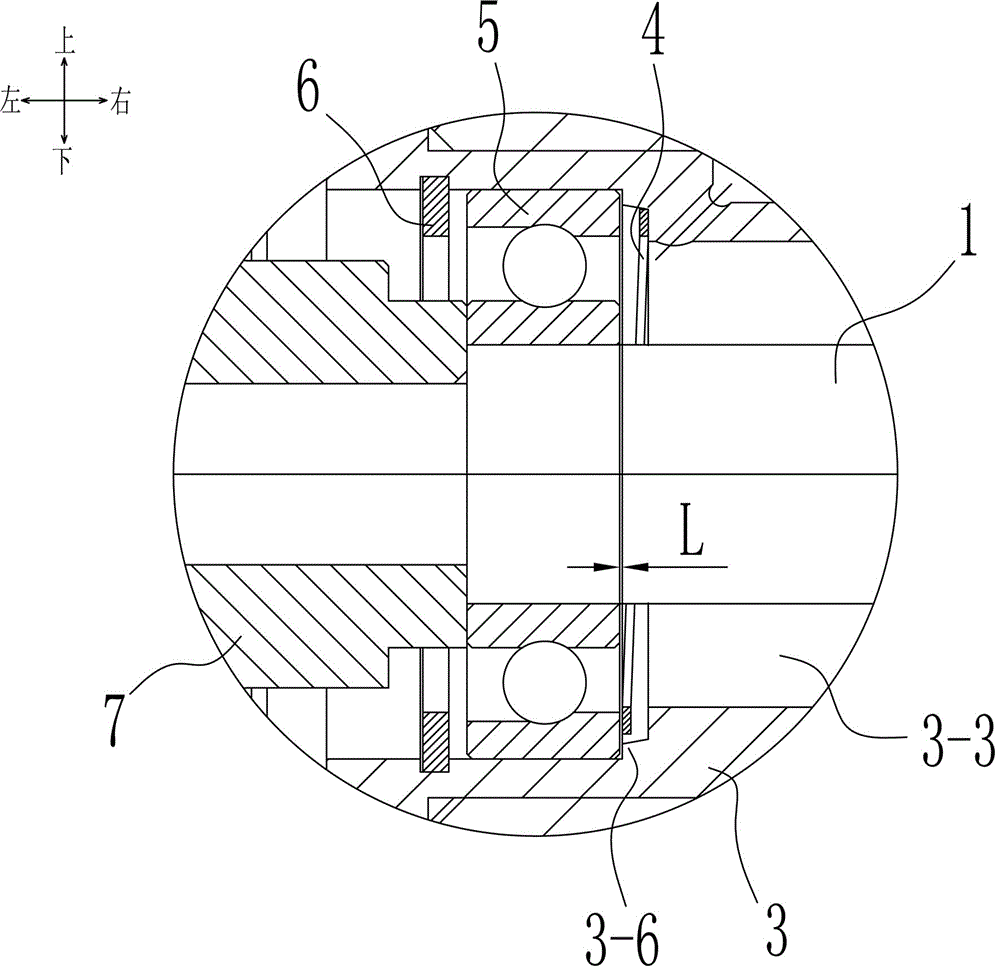

[0026] Such as figure 2 and 3 Shown is a turbocharger, which includes a bearing body 16, a turbine rotor shaft 1, a pressure end seal ring 10, an oil baffle plate 11, an O-ring 13, an oil seal screw 14, a spring pin 15, and a heat shield 17. Turbine end seal ring 18, oil seal cover 12, shaft seal sleeve 7, compressor impeller 8 and impeller lock nut 9, and also include bearing sleeve 3 and two angular contact bearings 5 as described in Embodiment 1; The oil seal cover 12 fixes and connects the shaft bearing sleeve 3 into the bearing body 16, the shaft seal sleeve 7 and the compressor impeller 8 are sequentially arranged on the turbine rotor shaft 1, and the turbine The impeller lock nut 9 at the left end of the rotor shaft 1 is fastened.

[0027] The two angular contact bearings 5 are set on the turbine rotor shaft 1, the bearing sleeve 3 is set on the turbine rotor shaft 1, and the two angular contact bearings 5 are arranged on the bearing sleeve 3 In the bearing po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com