Fan rotation speed control method, control system and water tank

A technology of fan speed and control method, which is applied in pump control, mechanical equipment, machines/engines, etc., can solve the problems of out-of-sync frequency conversion compressor and fan speed, waste of cooling capacity distribution, waste of cooling capacity of compressors, etc., to achieve optimization The effect of opening and stopping time of the refrigerator, improving cooling speed, and simple control method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

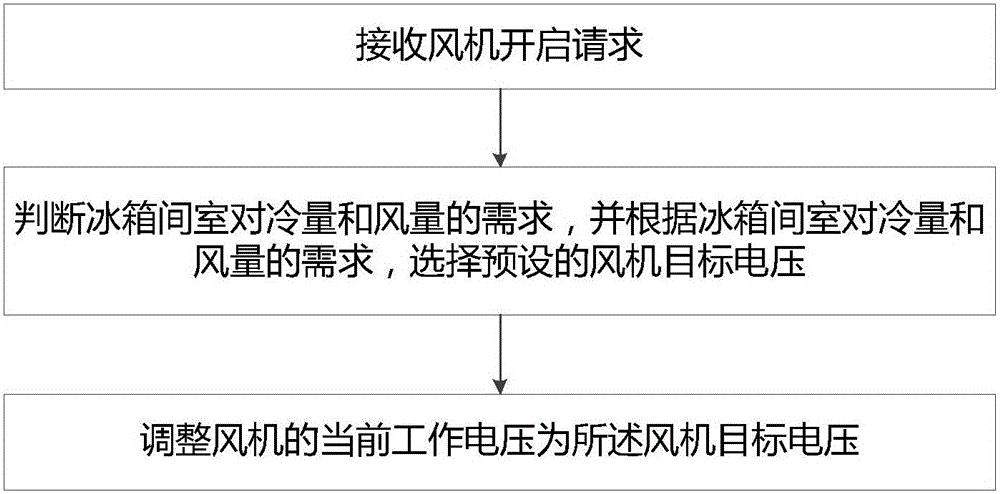

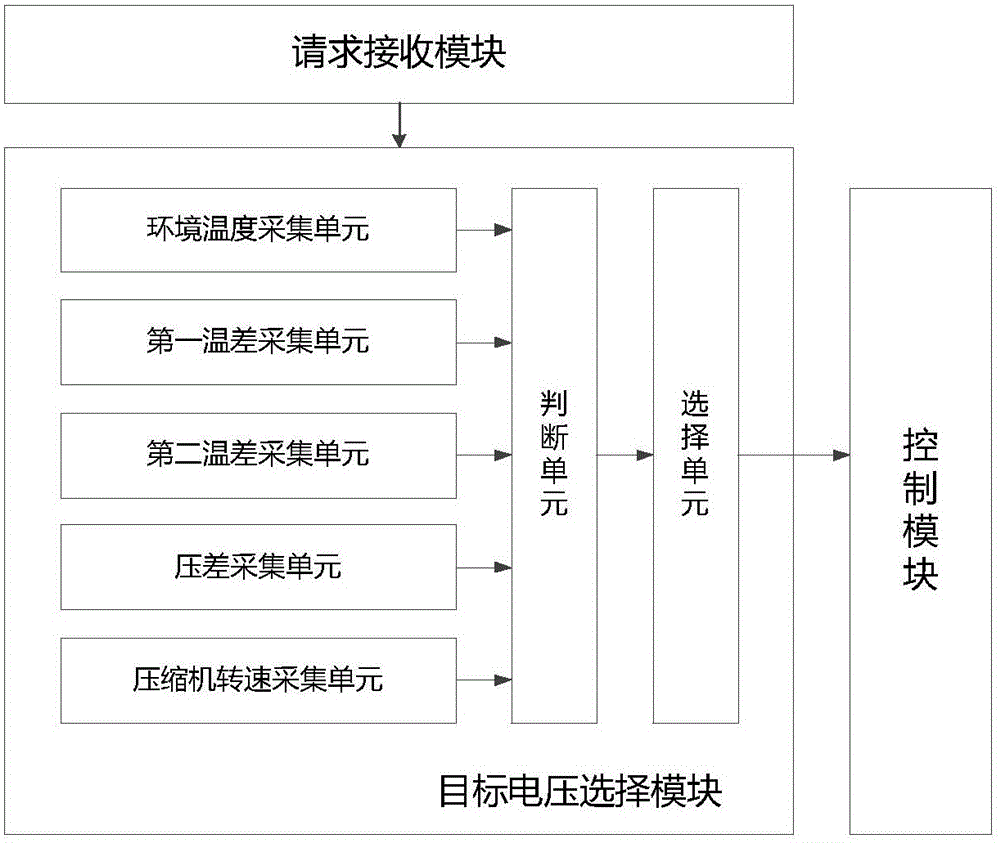

[0103] Example 2, such as figure 2 Said, a fan speed control system, comprising: a request receiving module, used to receive a fan start request; a target voltage selection module, used to judge the cooling capacity and air volume demand of the refrigerator compartment, and according to the cooling capacity of the refrigerator compartment According to the demand of air volume, select the preset target voltage of the fan; the control module is used to adjust the current working voltage of the fan to the target voltage of the fan. In this embodiment, the target voltage selection module includes a first temperature difference acquisition unit, a second temperature difference acquisition unit, a pressure difference acquisition unit, an ambient temperature acquisition unit, a compressor speed acquisition unit, a judgment unit, and a selection unit. The temperature difference collection unit is used to collect the room temperature difference between the refrigerators; the second te...

Embodiment 3

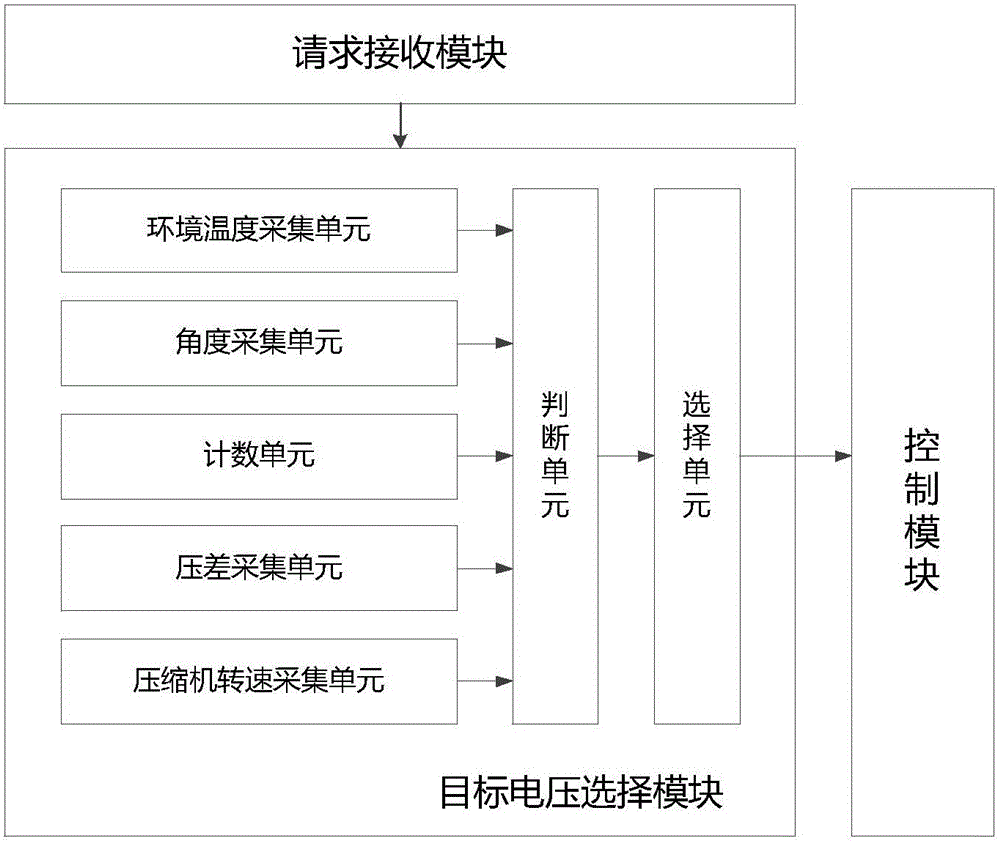

[0104] Example 3, such as image 3 Said, another fan speed control system, the target voltage selection module includes an angle acquisition unit, a counting unit, a pressure difference acquisition unit, an ambient temperature acquisition unit, a compressor speed acquisition unit, a judgment unit and a selection unit, the angle The collection unit is used to collect the opening angle of the damper of the compartment; the counting unit is used to count the number of openings of the damper of the compartment; the differential pressure collection unit is used to collect the differential pressure between the air outlet and the return air outlet of the refrigerator; The ambient temperature acquisition unit is used to collect the current ambient temperature; the rotational speed acquisition unit is used to collect the current compressor rotational speed; the judging unit is used to judge the preset temperature range where the current ambient temperature is located, and generate a fir...

Embodiment 4

[0105] Example 4, such as Figure 4 Said, including the fan speed control system mentioned above.

[0106] In the description of the present invention, it should be understood that the terms "first" and "second" are used for description purposes only, and cannot be interpreted as indicating or implying relative importance or implicitly indicating the quantity of indicated technical features. Thus, the features defined as "first" and "second" may explicitly or implicitly include at least one of these features. In the description of the present invention, "plurality" means at least two, such as two, three, etc., unless otherwise specifically defined.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com