Construction method for integral installation of river-crossing sinking pipe

An overall installation and construction method technology, applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems such as poor pressure bearing capacity, high cost, difficult to eliminate quality defects, etc. The effect of reducing the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

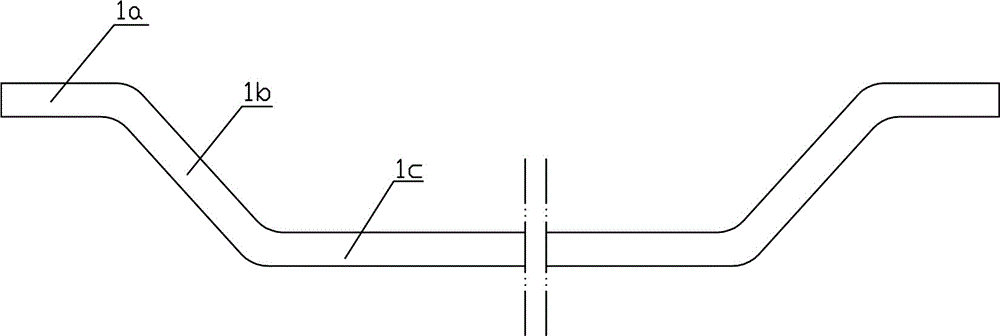

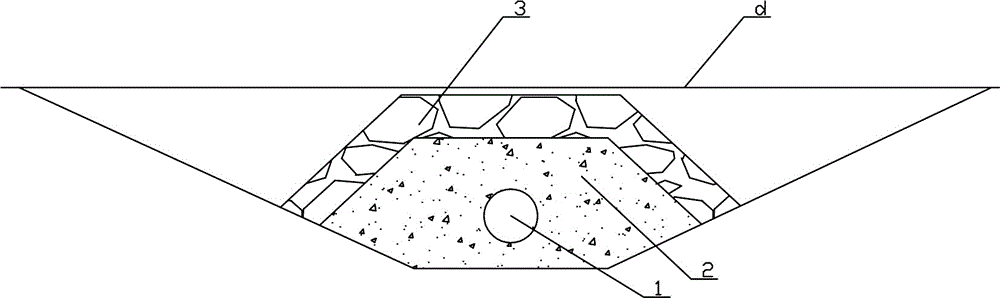

[0032] like Figure 1~4 Among them, a construction method for the overall installation of immersed tubes across the river, including the following steps:

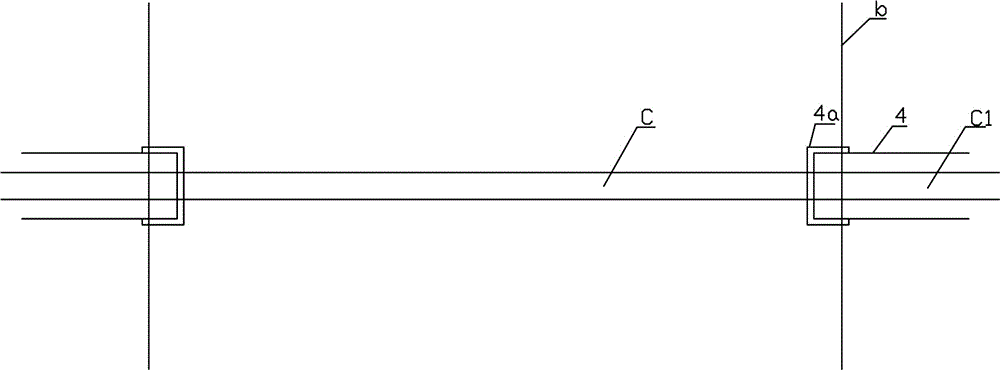

[0033] 1. At the position c1 of the river bank trench on both sides of the river, steel sheet piles are driven to form a cofferdam;

[0034] In the preferred scheme, the steel sheet piles are Larsen steel sheet piles. In this example, 12m and 15m Larsen steel sheet piles are used for the steel sheet piles, and a cofferdam is formed at a position close to the sideline b of the river bank. It consists of a steel sheet pile 4 and a second longitudinal steel sheet pile 4a. The second steel sheet pile 4a is provided with two Larsen steel sheet piles to prevent water from entering the cofferdam.

[0035] In a preferred solution, steel supports are set between two rows of first steel sheet piles 4 according to the excavation depth of the river bank trench c1. During the excavation of the river bank pipe ditch c1, the ratio of 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com