Air adding and pressurizing device of rotary kiln drying system

A pressurization device and drying system technology, applied in the direction of drying gas arrangement, drying, dryer, etc., can solve the problem that the air volume, air temperature, and air pressure cannot meet the drying needs, and achieve the effect of ensuring drying and sintering quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

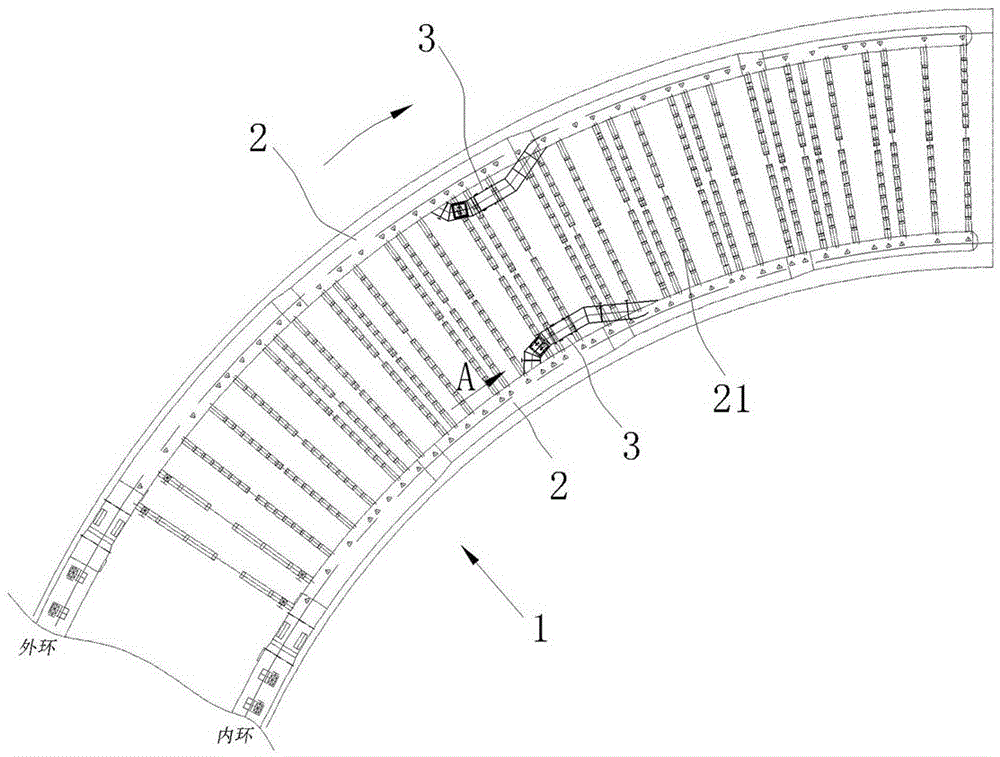

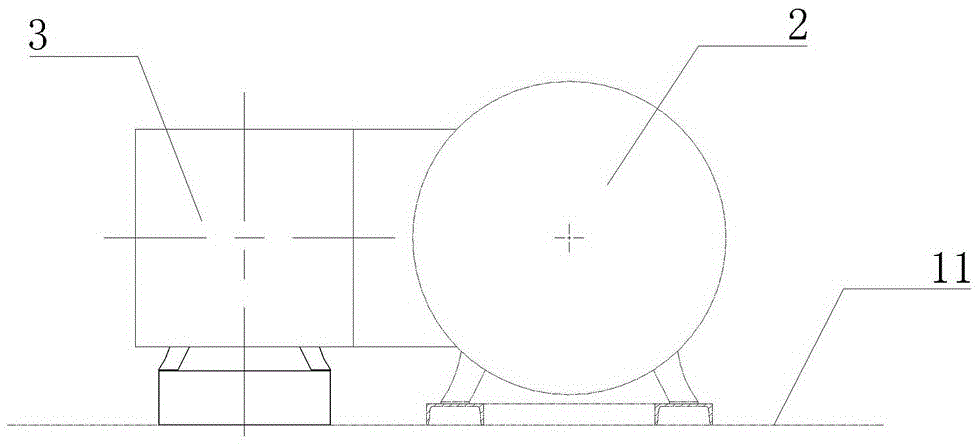

[0024] Such as Figure 1~3 As shown, a wind booster device for a rotary kiln drying system, the wind booster device 3 is connected in parallel with the heat-sending main air duct 2 in the rotary kiln drying system, and of course each heat-sending main air duct 2. It is not limited to a set of air increasing and boosting device 3. During specific implementation, a set of heat-sending main air ducts 2 on the outer ring and the inner ring is provided.

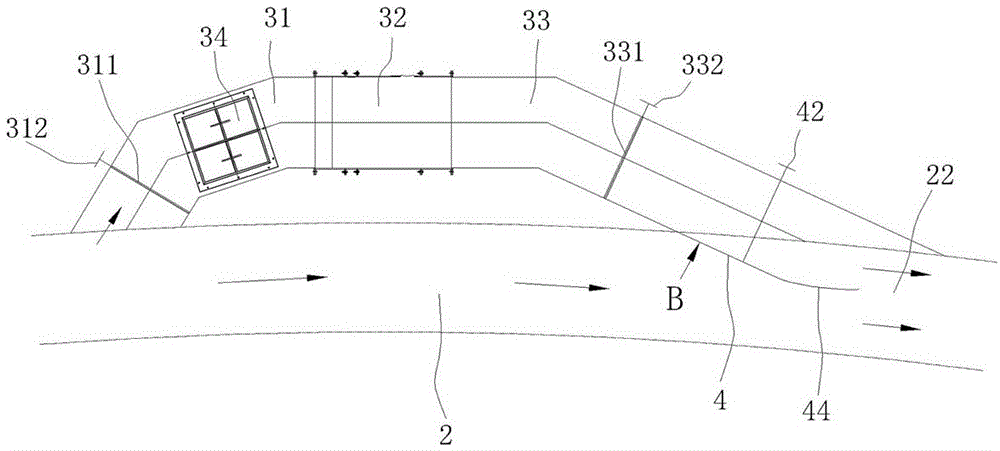

[0025] Such as figure 2 As shown, the air booster device 3 is followed by an air inlet pipe 31, a fan 32, and an air outlet pipe 33 along the air supply direction. The air inlet pipe 31 is provided with an air inlet regulating gate 311 near the end of the heat supply main air pipe 2. The air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com