Work method for hydraulic heat exchange system with impact-resistance energy accumulation radiator

A technology of heat exchange system and working method, which is applied in the field of hydraulic heat exchange system, can solve the problems of increased pressure, unbalanced flow, easily damaged radiator, and scrapped, etc., and achieves the effect of not easy to be damaged and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

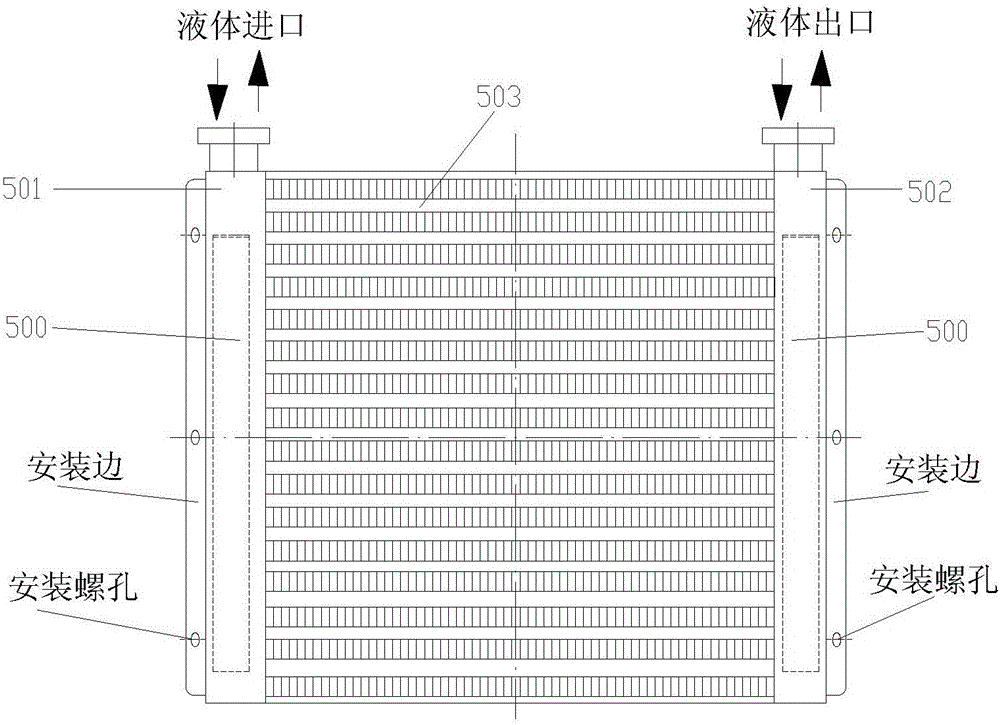

[0046] The accumulator tube is built in. When the liquid inlet and outlet of the anti-impact energy storage radiator are located on the top of the first liquid collection tank 501 and the second liquid collection tank 502, the energy storage tube 500 is installed in the first liquid collection tank 501 and the second liquid collection tank 502. The inside of the second liquid collection tank 502 is enough.

Embodiment 2

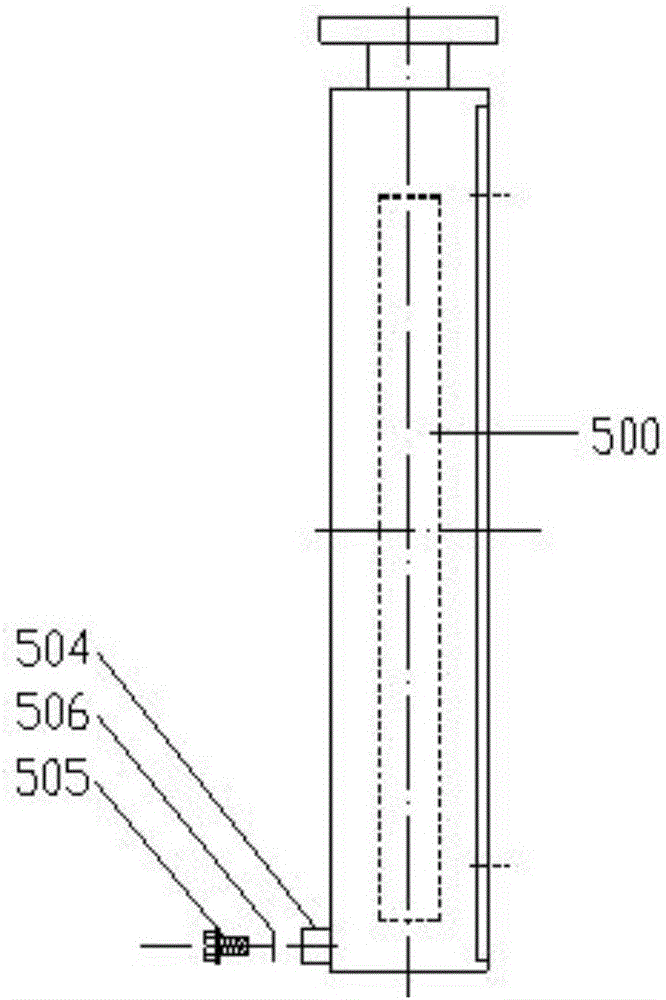

[0048] The accumulator tube is built in, and when the liquid inlet and outlet of the anti-impact energy storage radiator are located on the sides of the first liquid collection tank 501 and the second liquid collection tank 502, the energy storage tube 500 is installed on the first liquid collection tank 501 and the second liquid collection tank 502. Inside the second liquid collecting tank 502, if the height of the accumulator tube 500 is higher than the height of the liquid inlet and the liquid outlet, no other treatment is required; if the height of the accumulator tube 500 is lower than the height of the liquid inlet and the liquid outlet , it is necessary to install a diverter baffle 507 on the top of the energy storage tube 500, the diverter baffle 507 separates the liquid inlet and outlet from the diverter liquid tank 503 at the corresponding height, so as to avoid the direct impact of the liquid into the diverter liquid tank 503 .

Embodiment 3

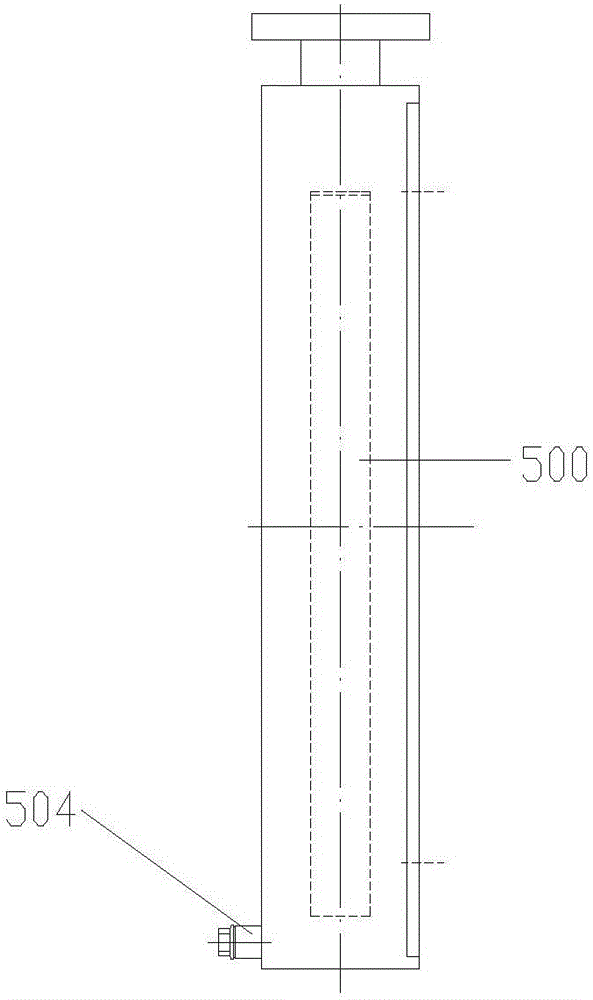

[0050] The energy storage tube is placed outside, and the liquid inlet and liquid outlet of the anti-impact energy storage radiator are located at the top of the first liquid collection tank 501 and the second liquid collection tank 502 . The opening at the bottom of the accumulator tube 500 is threadedly connected to the connection ports on the bottom side of the first sump 501 and the second sump 502, and the top of the accumulator tube 500 is connected to the first sump 501 and the second sump. The mounting edge on the top side of the liquid tank 502 is fixedly connected by bolts, which is convenient for disassembly and assembly. Because the energy storage tube 500 of the anti-shock energy storage radiator is arranged outside the first liquid collection tank 501 and the second liquid collection tank 502, it is possible to select different capacity and various energy storage tubes according to the difference in liquid flow and impact force. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com