Method for detecting fastening-down temperature of long seamless rail

A technology of seamless lines and locked rail temperature, applied in thermometers, measuring heat, measuring devices, etc., can solve the problems of lack of stress, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

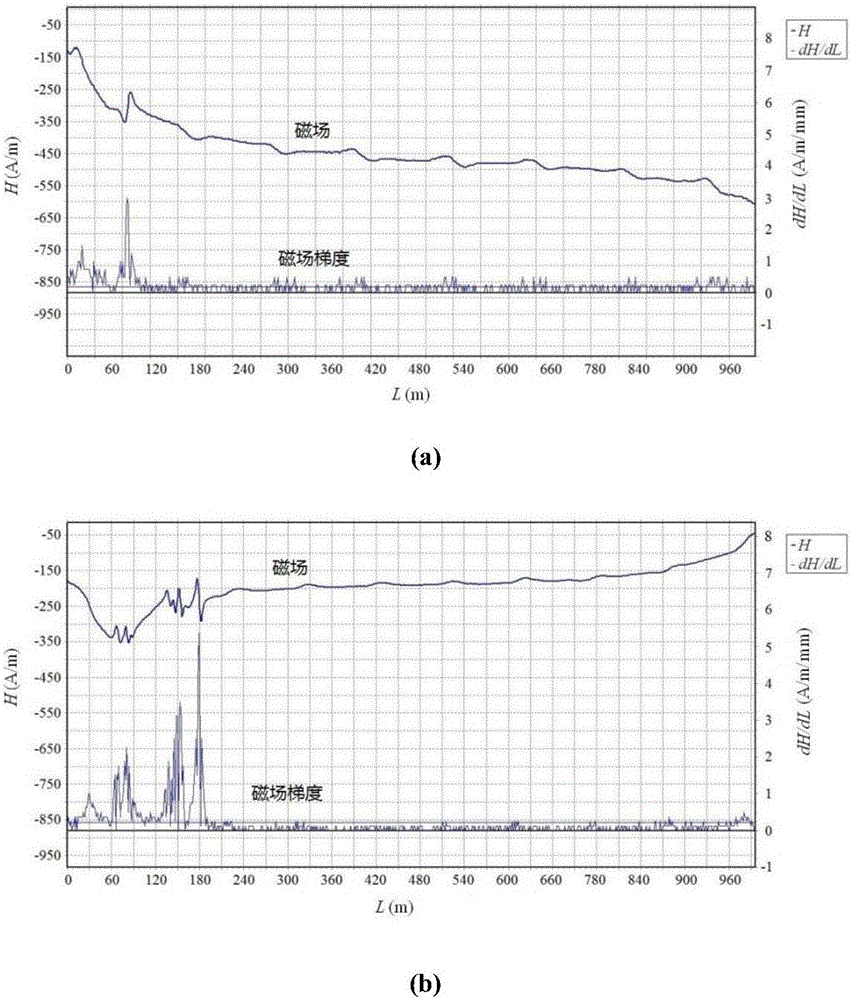

[0032] Using a self-made system to detect the temperature stress of a 1100m downlink seamless line in service in a section of a railway bureau in China. Among them, the stretching area at both ends of the line is 100m, and the fixed area in the middle is 900m. The rail specification of this line is U74 type 60Kg / m rail, and its cross-sectional area A=77.45cm 2 , the moment of inertia is I=3217cm 4 , elastic modulus E=2.06×10 5 MPa, coefficient of thermal expansion α=1.18×10 5 m / °C, the sleeper configuration is 1840 pieces / Km type II concrete sleeper, the sleeper spacing is 0.568m, the length is 2.6m, the cross-sectional width of the sleeper is 0.25m, the height is 0.2m, and the elastic modulus of the sleeper is E tie =1.5×10 4 MPa, the initial track bed lateral resistance is 12.1N / mm. The inspection was carried out at noon for two consecutive days, and a total of two inspections were performed. The on-site rail temperatures were 36°C and 42°C respectively, and the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com