Wheel rim driven propeller thruster test device

A propeller propeller and test device technology, which is applied in fluid dynamics test, measuring device, machine/structural parts test, etc., can solve the problems of difficult motor sealing, large error of thrust method, and difficult to achieve motor power, etc., to achieve High propulsion efficiency, avoiding cavitation and cavitation, reducing vibration noise and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the present invention is not limited.

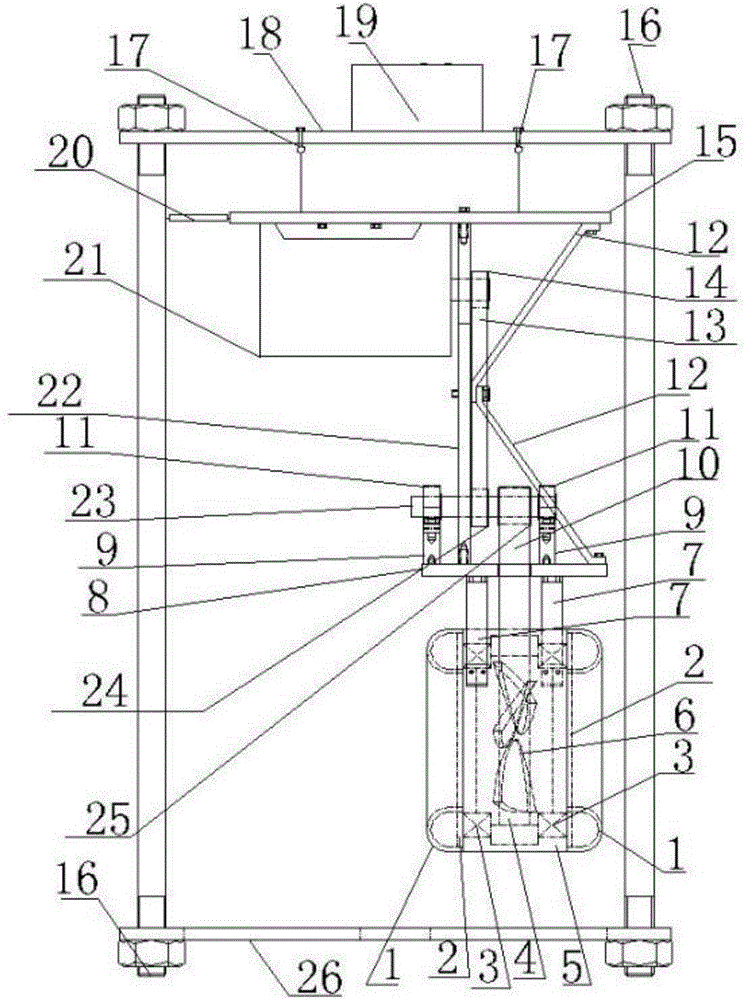

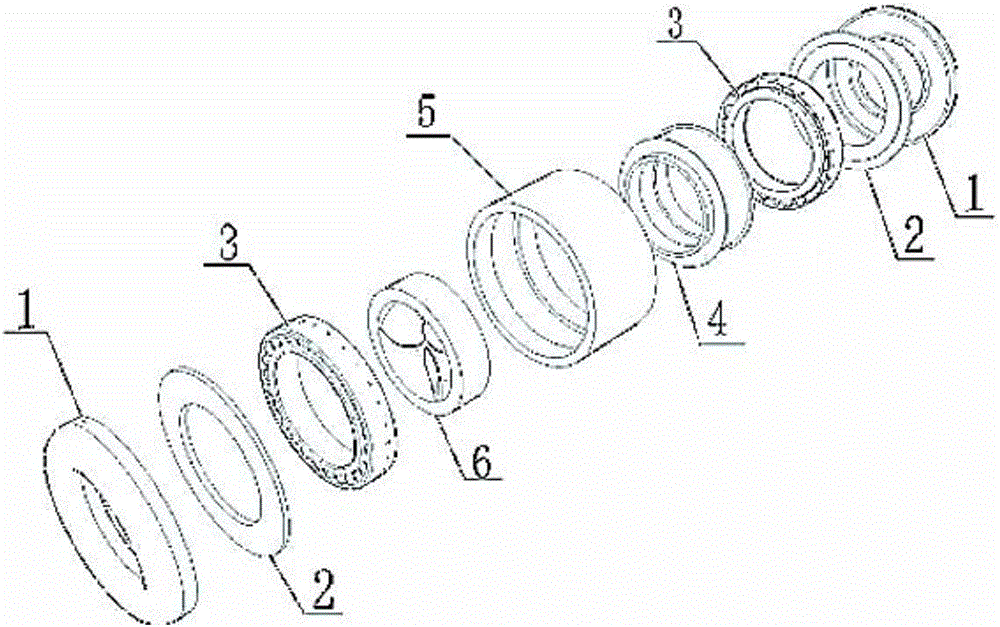

[0027] The rim-driven propeller propeller test device provided by the invention has a structure such as figure 1 As shown, it includes a propulsion unit and a support unit. The support unit is mainly composed of a support mechanism and a platform, and the entire propulsion unit is suspended on the platform by the support mechanism.

[0028] The support mechanism includes a receiving plate 8, a space V-shaped bracket 7, an intermediate bearing seat 9, a vertical plate 22, an inclined bracket 12, and a top plate 15, wherein: the receiving plate 8 and the vertical plate 22, the vertical plate 22 and the upper top plate 18 Four-hole thread connection is adopted, and the connection is strengthened by the inclined bracket 12; the middle bearing seat 9 is fixed on both sides of the vertical plate 22. The space V-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com