Production method of full-color electronic paper

A production method and technology of electronic paper, applied in nonlinear optics, instruments, optics, etc., can solve the problems of unable to display in color, electronic paper maintains a sufficiently high reflectivity, etc., and achieve ultra-low energy consumption and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

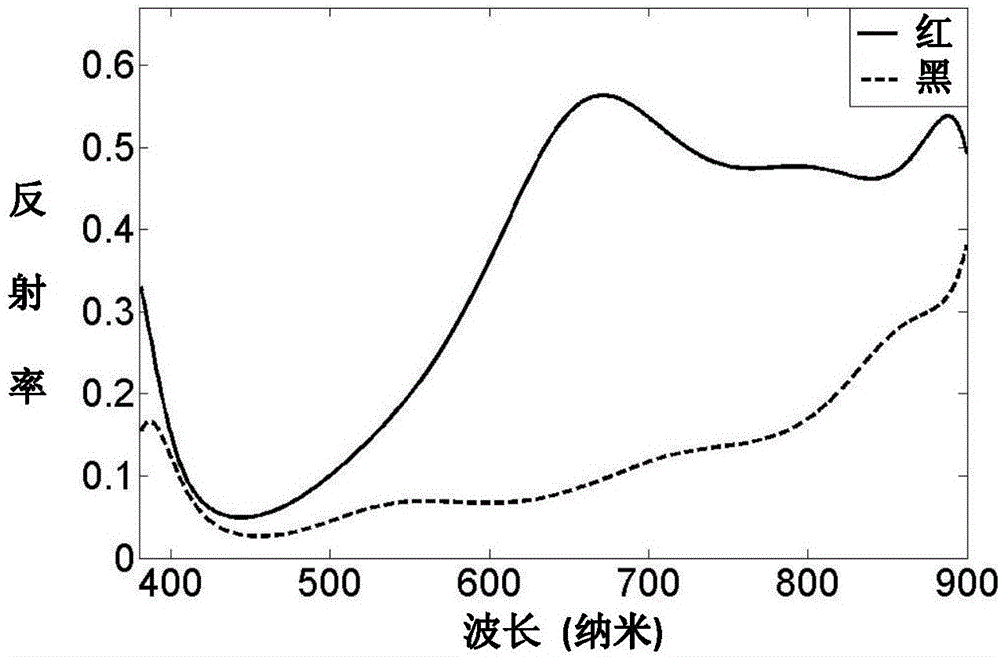

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

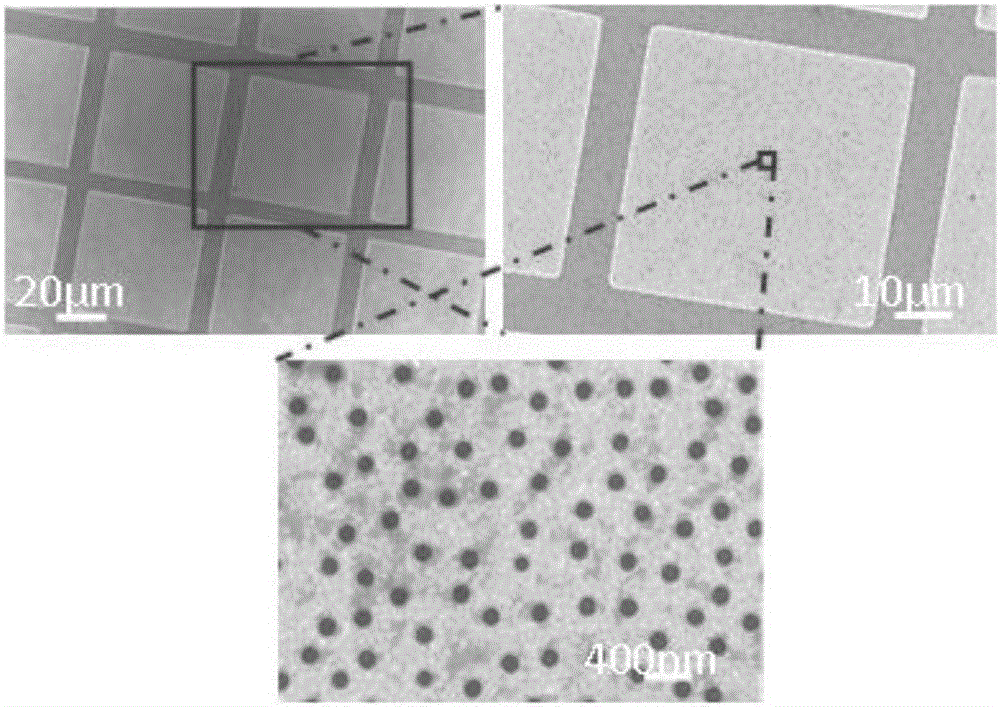

[0042] Embodiment 1: first prepare following various solutions:

[0043] 1. 0.1M sodium dodecylbenzenesulfonate solution (NaDBS): Weigh 34.8g sodium dodecylbenzenesulfonate and dissolve it in 1L deionized water, heat it to fully dissolve to form a colorless transparent solution, respectively The solution was stirred with a magnetic centrifuge for 20 minutes and then sonicated for an additional 20 minutes.

[0044] 2. 0.1 M pyrrole mixed solution: Weigh 314 μL of pyrrole (Pyrrole) solution and add it to the prepared 40 mL sodium dodecylbenzenesulfonate (NaDBS) solution. The solution was then stirred with a magnetic centrifuge for 20 minutes and deoxygenated and sonicated for 20 minutes at a temperature of 35°C.

[0045] 3. Mix 0.1M sodium dodecylbenzenesulfonate solution with 0.1M silver chloride solution: weigh 4.3g of silver chloride and dissolve in 1L of deionized water, and stir the solution with a magnetic centrifuge for 20 minutes. Take out 500mL of silver chloride solu...

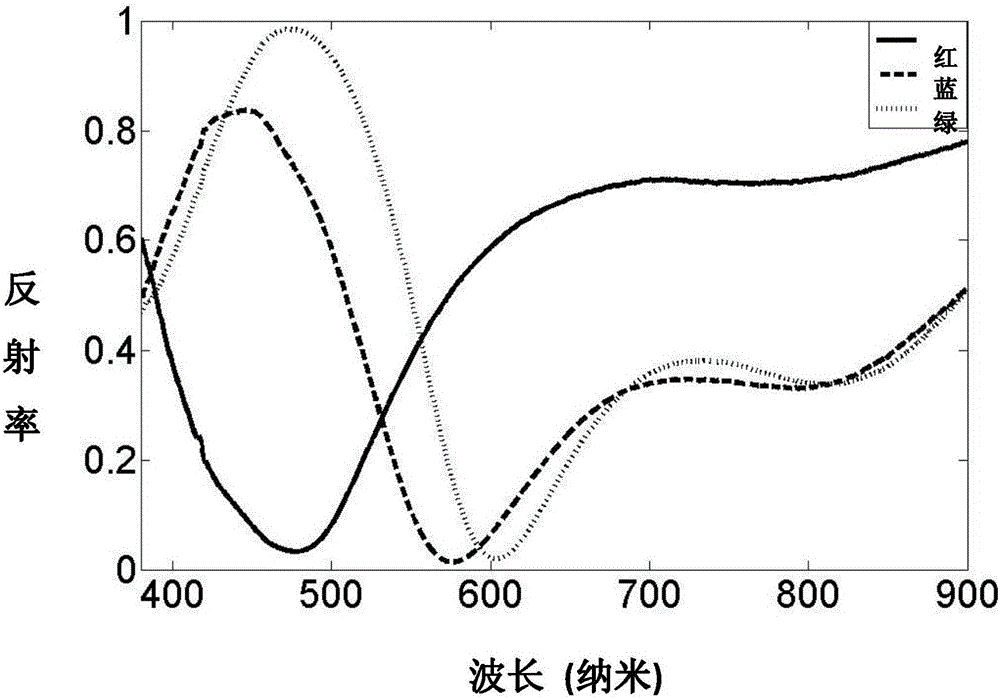

Embodiment 2

[0060] Embodiment 2: In this embodiment, the production of reflective blue light nanomaterial substrates is mainly introduced. The plastic substrate (PET) was immersed in 95% alcohol solution for cleaning and ultrasonically treated for 5 minutes. The substrate was then removed, rinsed with deionized water and dried. The source materials of chromium, silver and alumina are heated with an electron gun, and 5nm of chromium, 150nm of silver and 83nm of alumina are evaporated respectively. Others are the same as in Example 1.

Embodiment 3

[0061] Embodiment 3: In this embodiment, the production of reflective green light nanomaterial substrates is mainly introduced. The plastic substrate (PET) was immersed in 95% alcohol solution for cleaning and ultrasonically treated for 5 minutes. The substrate was then removed, rinsed with deionized water and dried. The source materials of chromium, silver, and alumina are heated with an electron gun, and 5nm of chromium, 150nm of silver, and 93nm of alumina are evaporated respectively. Others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com