RFID-based maintenance recording system and method for workshop production equipment

A technology for maintenance records and production equipment, applied in the direction of collaborative devices, instruments, calculations, etc., can solve the problems of low reliability, poor sharing, inconvenience, etc., and achieve RFID signal interference prevention, large storage capacity, and easy use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

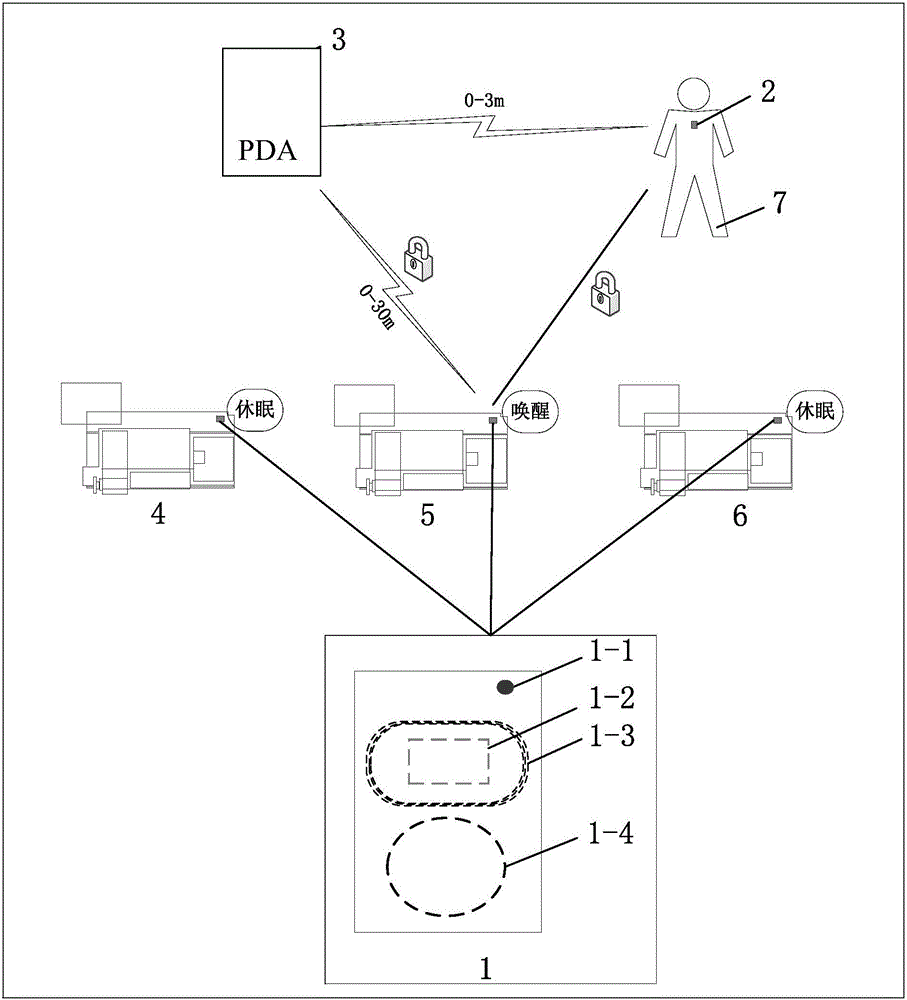

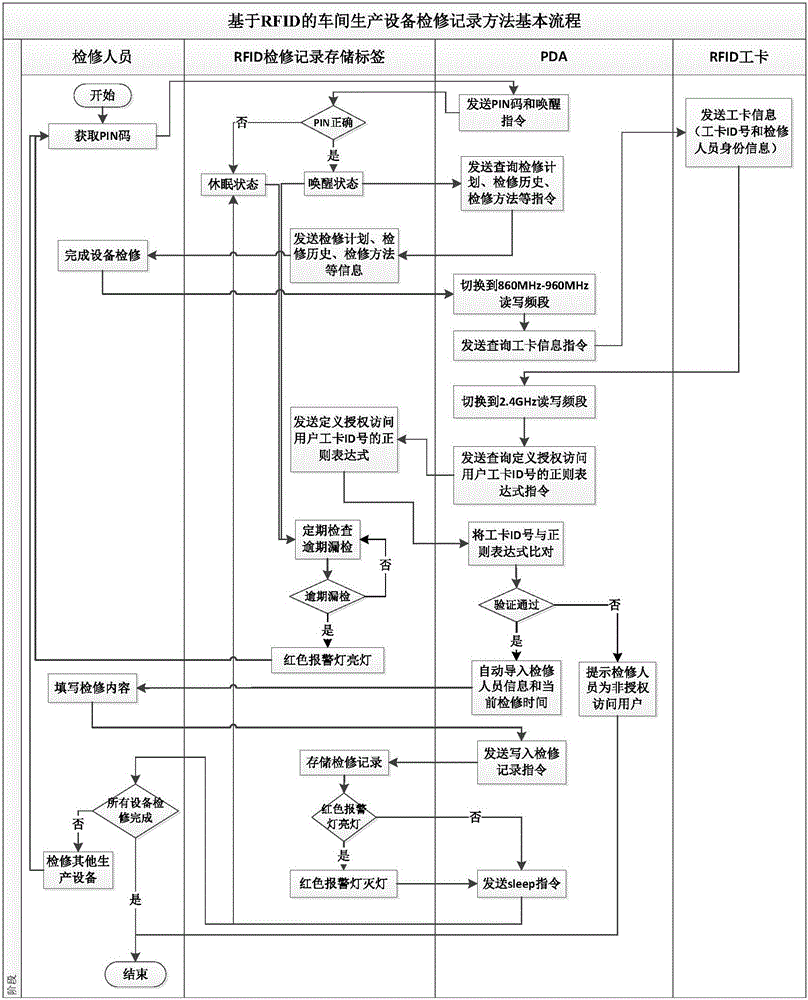

[0039] Such as figure 1 As shown, there are several production equipment distributed in the workshop, and each equipment is equipped with an active RFID tag, that is, the maintenance record storage label, the label has an alarm indicator light, the working voltage is 3.6V, the working frequency is 2.4GHz, and the storage capacity It is 512KB, and the effective reading distance is up to 30m. The battery used is a button battery. It records the basic information of the production equipment, authorized access users, maintenance methods, maintenance history and maintenance plan, and has an overdue alarm function. The overdue alarm function is mainly through The red warning light is used to trigger the alarm. The basic information of the equipment, authorized access users, maintenance methods and maintenance plans are written in advance by the management personnel of the equipment management department. The authorized access users are encrypted and stored, and maintenance personnel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com