Directional coupler used for measuring microwave power of gyrotron traveling wave tube and manufacturing method for directional coupler

A directional coupler, microwave power technology, applied in the direction of waveguide type devices, electrical components, connecting devices, etc., can solve the problem of large influence of microwave absorption characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

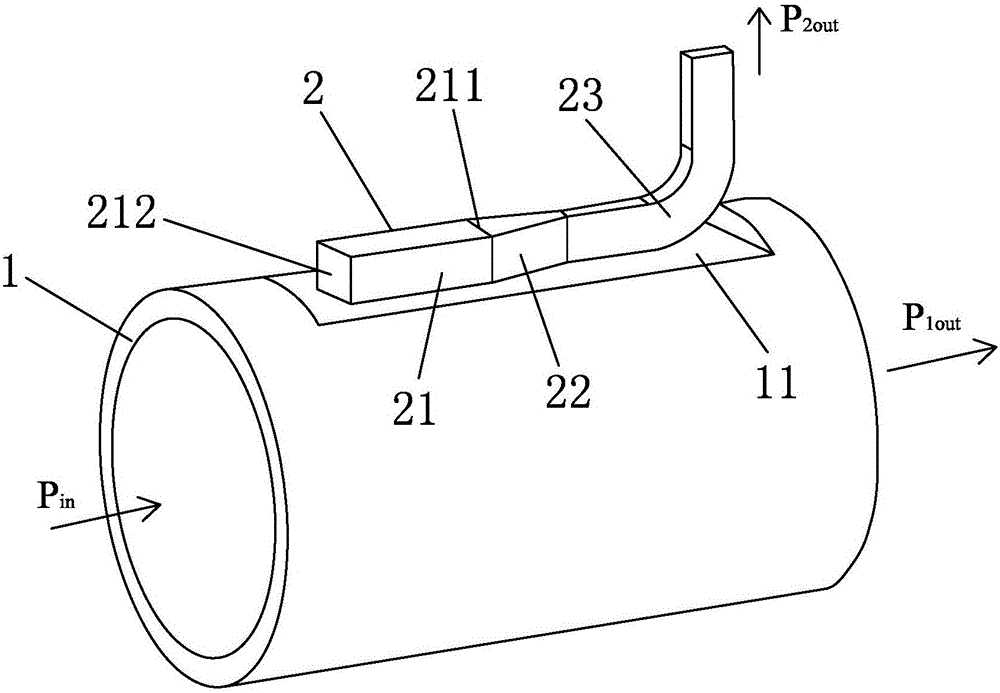

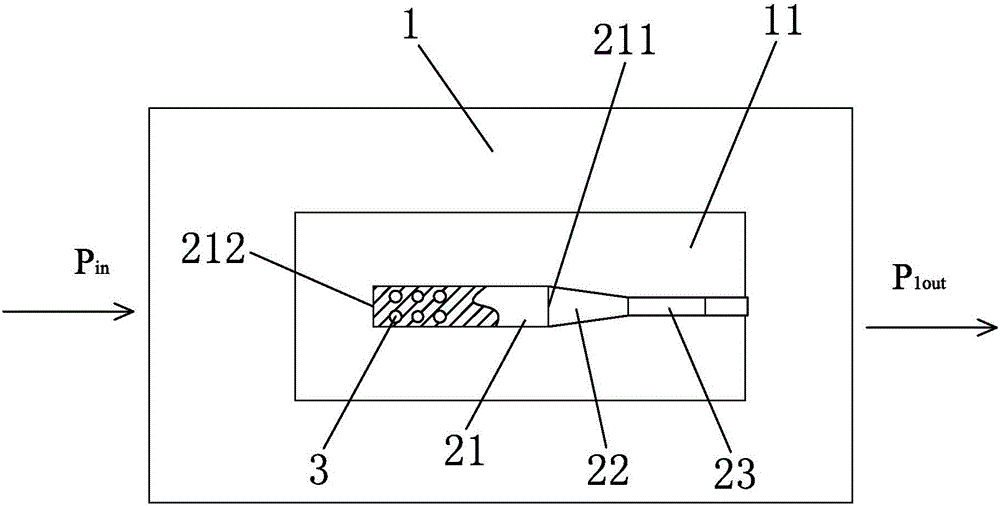

[0081] Such as Figures 1 to 4 As shown, a directional coupler for microwave power measurement of a gyrotron traveling wave tube, the coupler is a three-port device, which includes a main waveguide 1 and a matching secondary waveguide 2 arranged on the side wall of the main waveguide 1 , the outer surface 11 of the side wall of the circular waveguide 1 connected and fixed to the secondary waveguide 2 is arranged in a plane.

[0082] The main waveguide 1 has an input port P in and the output port P 1out The circular waveguide; the secondary waveguide 2 includes a square waveguide 21, a transition waveguide 22 and an output port P 2out a rectangular waveguide 23; the square waveguide 21 in the secondary waveguide 2 has one end port 211 connected to the transition waveguide 22, and the other end port 212 is a closed port, and the closed port 212 is also the closed port of the secondary waveguide 2;

[0083] Between the inner cavity of the circular waveguide and the inner cavit...

Embodiment 2

[0092] Such as Figures 1 to 6 Shown, the present invention provides a kind of manufacturing method of above-mentioned directional coupler, and this method comprises the following steps:

[0093] S1. According to the output characteristics of the gyrotron TWT and the power detection range of the measuring instrument, determine the design goal of the directional coupler, which includes the working frequency band, coupling degree and working bandwidth;

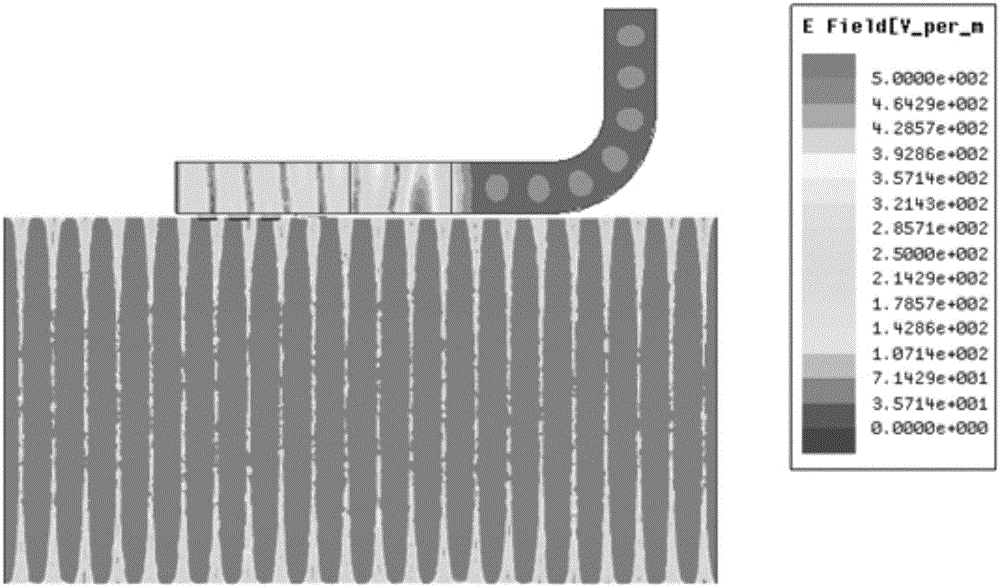

[0094]S2. According to the design goal of the directional coupler, determine the initial condition of the coupling hole on the directional coupler. The initial condition of the coupling hole includes the shape of the coupling hole and the distribution mode of the coupling hole; the shape of the coupling hole in this embodiment is a circle shape, the coupling holes are distributed in double rows along the axial direction of the circular waveguide;

[0095] S3. According to the shape of the coupling holes and the distribution mod...

Embodiment 3

[0119] Such as Figure 1 to Figure 4 , Figure 7 , 8 Shown, the present invention provides another kind of manufacturing method of above-mentioned directional coupler, and this method comprises the steps:

[0120] S1. According to the output characteristics of the gyrotron TWT and the power detection range of the measuring instrument, determine the design goal of the directional coupler, which includes the working frequency band, coupling degree and working bandwidth;

[0121] S2. According to the design goal of the directional coupler, determine the initial condition of the coupling hole on the directional coupler. The initial condition of the coupling hole includes the shape of the coupling hole and the distribution mode of the coupling hole; the shape of the coupling hole in this embodiment is a circle shape, the coupling holes are distributed in double rows along the axial direction of the circular waveguide;

[0122] S3. According to the shape of the coupling holes and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com