Intensive bus duct

A busway, intensive technology, used in busbar installation, cooling busbar devices, fully enclosed busbar devices, etc., to achieve the effect of improving overload capacity, reducing noise, and facilitating tapping and feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

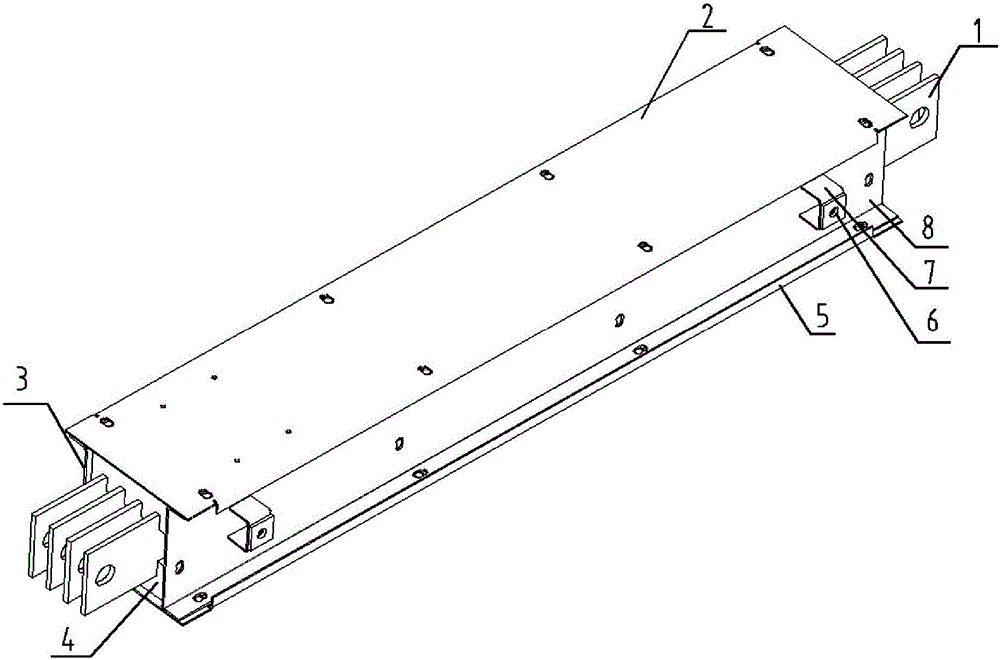

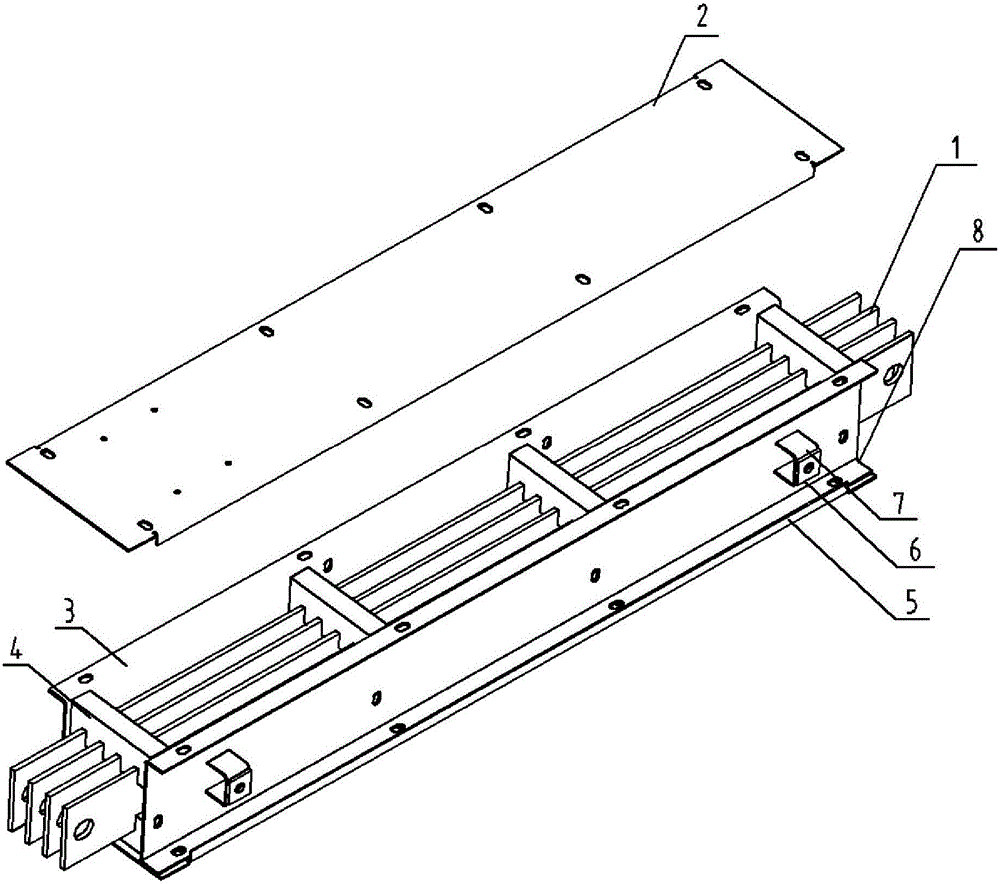

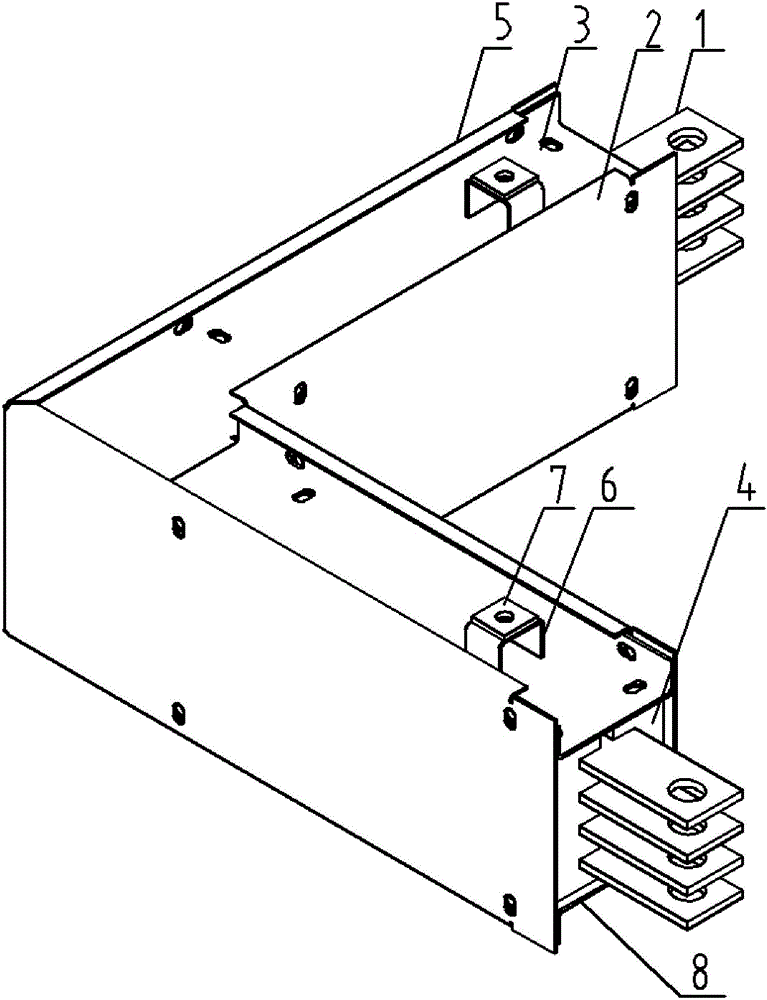

[0024] like figure 1 and figure 2 As shown, a dense bus duct includes a tank body and an insulating support 4 and a conductive component 1 located inside the tank body. The insulating support 4 supports the conductive component 1, so that there is a gap between the conductive component 1 and the inner wall of the tank. The gap, the conductive component 1 is arranged along the length direction of the tank body and its end protrudes from the end of the tank body. The conductive component 1 is composed of a plurality of busbars arranged in parallel and spaced apart from each other and the two ends are respectively flush. The distance between any adjacent two of the busbars is equal, 16-20mm. In this embodiment, the conductive component 1 is composed of four busbars, which are A-phase busbar, B-phase busbar, C-phase busbar and N-phase busbar arranged in sequence, A-phase busbar, B-phase busbar, C-phase busbar and N-phase busbar. The plugging method of the phase busbar is double...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com