A Current Decoupling Method Under Position Sensorless Control

A current decoupling and sensor technology, which is applied in the direction of controlling generators, controlling electromechanical brakes, controlling electromechanical transmissions, etc., can solve problems such as lack of research, and achieve the effects of improving estimation accuracy, sufficient decoupling, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

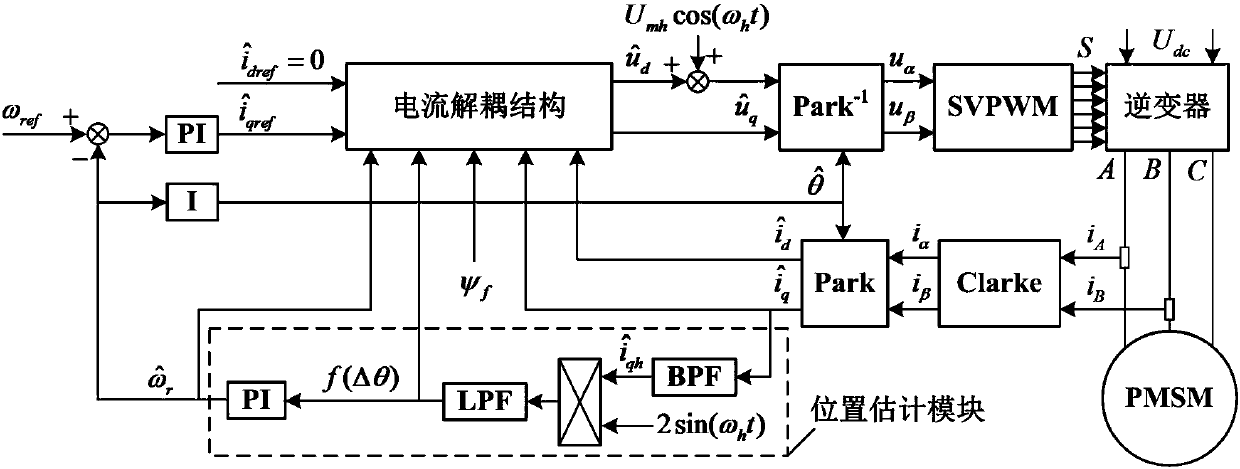

[0042] Such as Figure 5 Shown, the specific implementation steps of the present invention are:

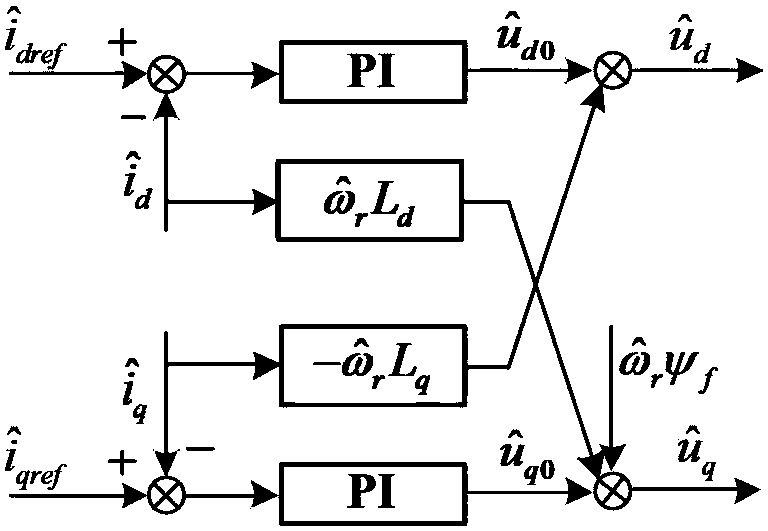

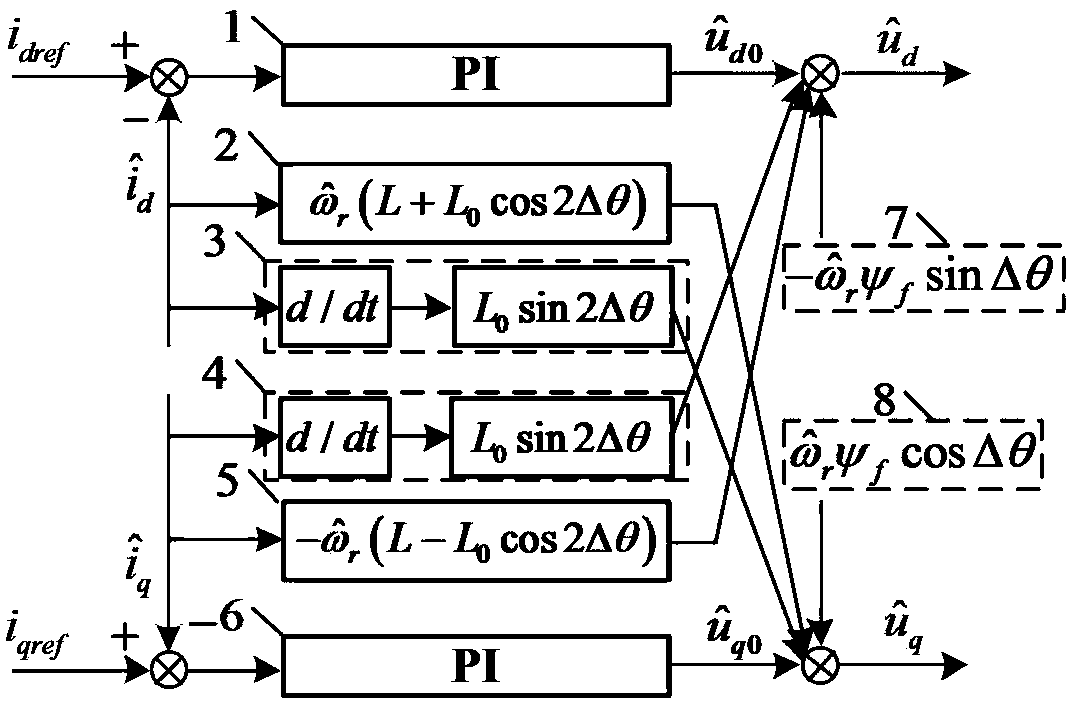

[0043] 1) The decoupling algorithm is used to obtain the estimated direct-axis and quadrature-axis voltage reference values.

[0044] 1.1) Obtain the estimated direct axis voltage reference value

[0045] 1.1.1) will estimate the direct axis current reference value with the estimated direct axis current feedback value The difference of the PI regulator is used as the input to read the output of the PI regulator in and The initial value of is 0.

[0046] 1.1.2) will estimate the quadrature axis current feedback value Estimated Rotor Angular Velocity and quadrature axis inductance L q Multiply the three to calculate the estimated quadrature axis current feedback value related items in and The initial value of 0; L q It is the parameter of the motor body, which can generally be obtained directly from the nameplate.

[0047] 1.1.3) will estimate the derivativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com