Emulsifying wax composition, preparation method and applications thereof

A composition and technology for emulsifying wax, applied in the direction of wax coatings, etc., can solve the problems of large average particle size, large expansion rate of water absorption thickness, poor stability of emulsifying wax, etc., and achieve the effect of small average particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

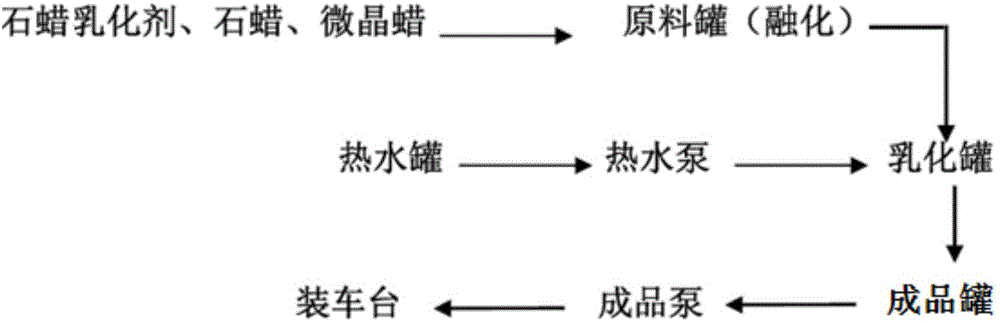

[0023] According to the present invention, the preparation method of the above-mentioned emulsified wax composition comprises: mixing paraffin wax emulsifier, paraffin wax and microcrystalline wax, and heating with or without a stabilizer, and then mixing and emulsifying the obtained mixture with water .

[0024] According to the present invention, based on 100 parts by weight of the emulsified wax composition, the amount of paraffin wax can be 15-50 parts by weight, the amount of microcrystalline wax can be 0.1-5 parts by weight, and the amount of paraffin wax emulsifier The amount can be 1-6 parts by weight, and the amount of water can be 40-80 parts by weight; preferably, based on 100 parts by weight of the emulsified wax composition, the amount of paraffin wax can be 25-40 parts by weight, The amount of the microcrystalline wax is 0.5-3 parts by weight, the amount of the paraffin emulsifier is 2-4 parts by weight, and the amount of the water is 55-70 parts by weight.

[0...

Embodiment 1

[0057] This example is used to illustrate the emulsified wax composition provided by the present invention and its preparation method.

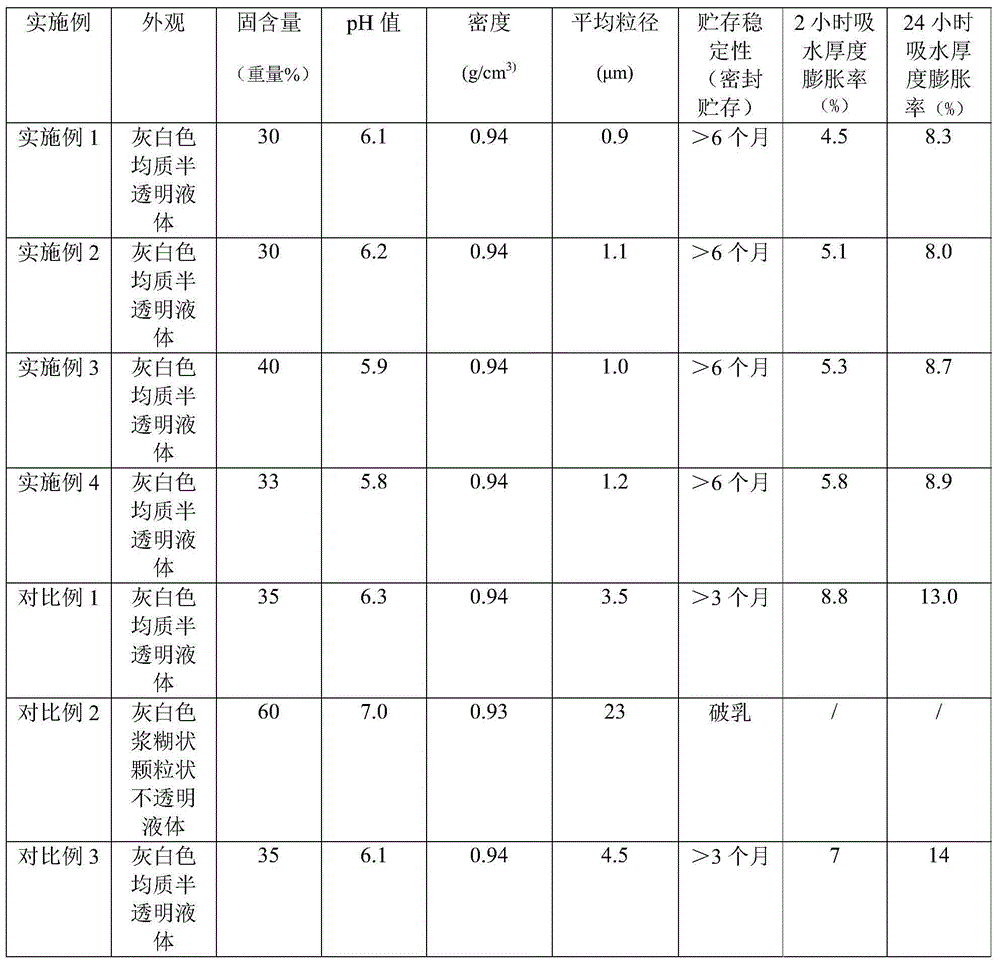

[0058] Raw materials are weighed according to parts by weight, and the specific formula of raw materials is as follows: No. 56 semi-refined paraffin wax (Yanshan Petrochemical production) 25% by weight, No. 70 microcrystalline wax 3.0% by weight (Jingmen Petrochemical Company production), emulsifier (Henan Provincial Road Pure Chemical Technology Co., Ltd., AG-105 cationic paraffin emulsifier, mainly containing lauryltrimethylammonium chloride) 2.0% by weight, calcium stearate 0.1% by weight, water 69.9% by weight.

[0059] Select paraffin wax, microcrystalline wax, emulsifier and stabilizer according to the above proportions, put them into a melting tank for heating, heat to 110°C and keep warm until they are completely melted to form a uniform mixture, and transport the resulting mixture to an emulsification tank , add hot water heated to 8...

Embodiment 2

[0064] This example is used to illustrate the reference emulsified wax composition and its preparation method.

[0065] Prepare the emulsified wax composition according to the method of Example 1, the difference is that the specific formula of the raw materials is as follows: No. 56 semi-refined paraffin wax (produced by Yanshan Petrochemical) 25% by weight, No. 70 microcrystalline wax 3.0% by weight (produced by Jingmen Petrochemical Company) , Emulsifier (Jiangsu Haian Petrochemical Plant, A-105 nonionic paraffin emulsifier, main component is fatty acid polyoxyethylene ester) 2.0% by weight, calcium stearate 0.1% by weight, water 69.9% by weight. An emulsified wax composition product is obtained. The obtained emulsified wax product is analyzed, and the obtained results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com