Steam generator design abundance calculating method

A technology of steam generator and calculation method, which is applied in the direction of calculation, instrument, special data processing application, etc., to achieve the effect of increasing accuracy and reducing risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with specific embodiments.

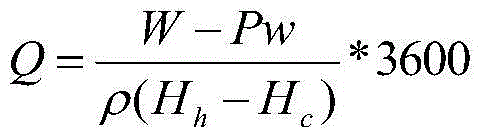

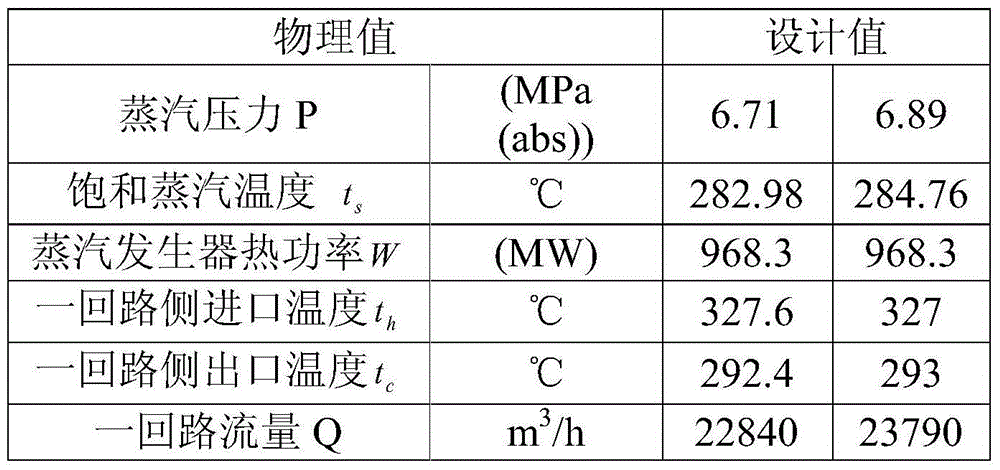

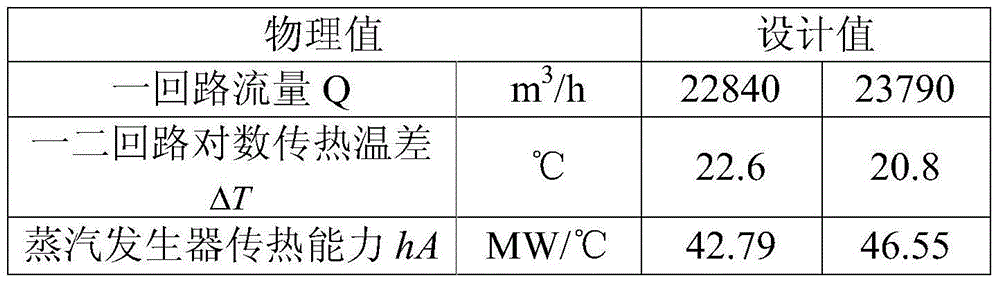

[0018] After the reactor reaches full-power steady-state operation, confirm the actual operating conditions and thermal power of the steam generator, confirm the heat transfer capacity of the steam generator, and compare it with the design value to confirm the margin of the evaporator. In the present invention, hA in the heat transfer calculation formula W=hAΔT is regarded as a unified expression form of heat transfer capacity, and the heat transfer coefficient and heat transfer area are not calculated separately.

[0019] The main steps of the steam generator design margin calculation method of the present invention include: after the first and second loops of the nuclear power plant are in full power and stable operation, shut down the steam generator for blowdown; conduct heat balance measurement of the first and second loops to obtain test data and results; according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com