Carbon rod filter element

A technology of filter elements and carbon rods, which is applied in the field of water treatment, can solve problems such as difficult treatment, difficult purification, complex components, etc., and achieve the effects of reducing costs, enhancing filtering effects, and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Take 5 ordinary sintered activated carbon rods with an outer diameter of 45mm, an inner diameter of 20mm, and a length of 180mm, and carry out different packaging according to the following methods:

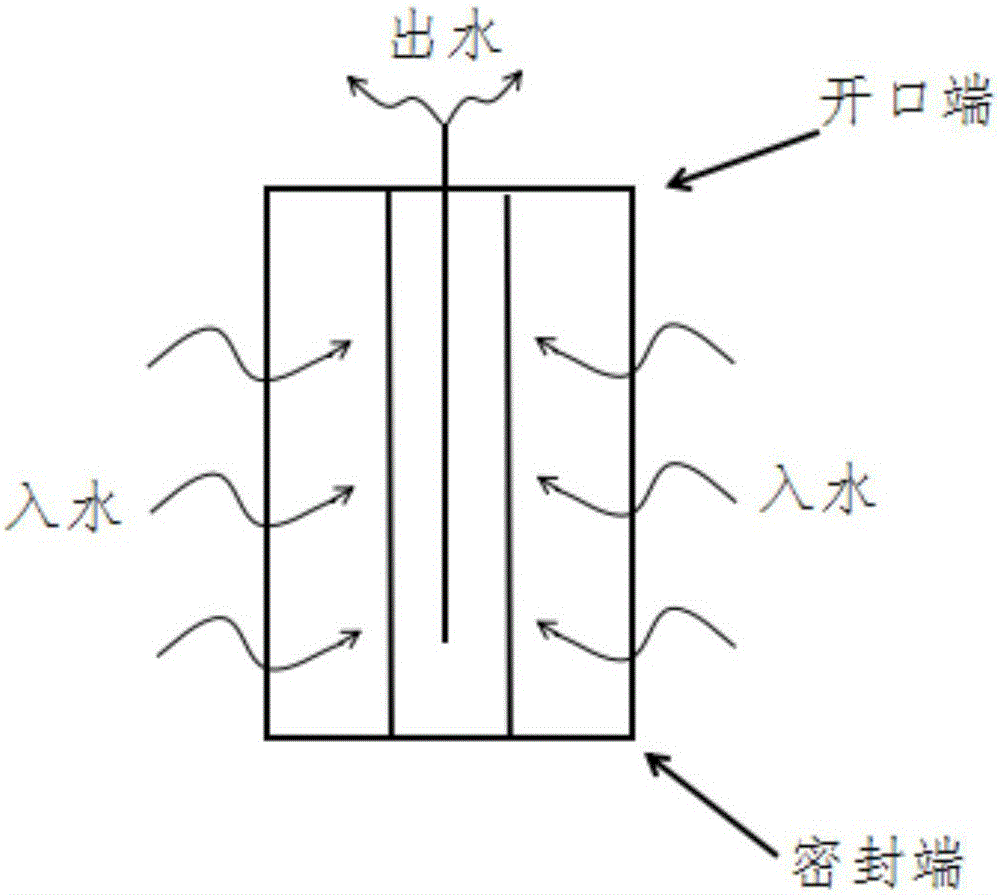

[0023] Carry out ordinary packaging of the carbon rod, one end is sealed with the lower end cap, and the other end is sealed with the upper end cap, which is used as the water outlet, which is recorded as sample A1;

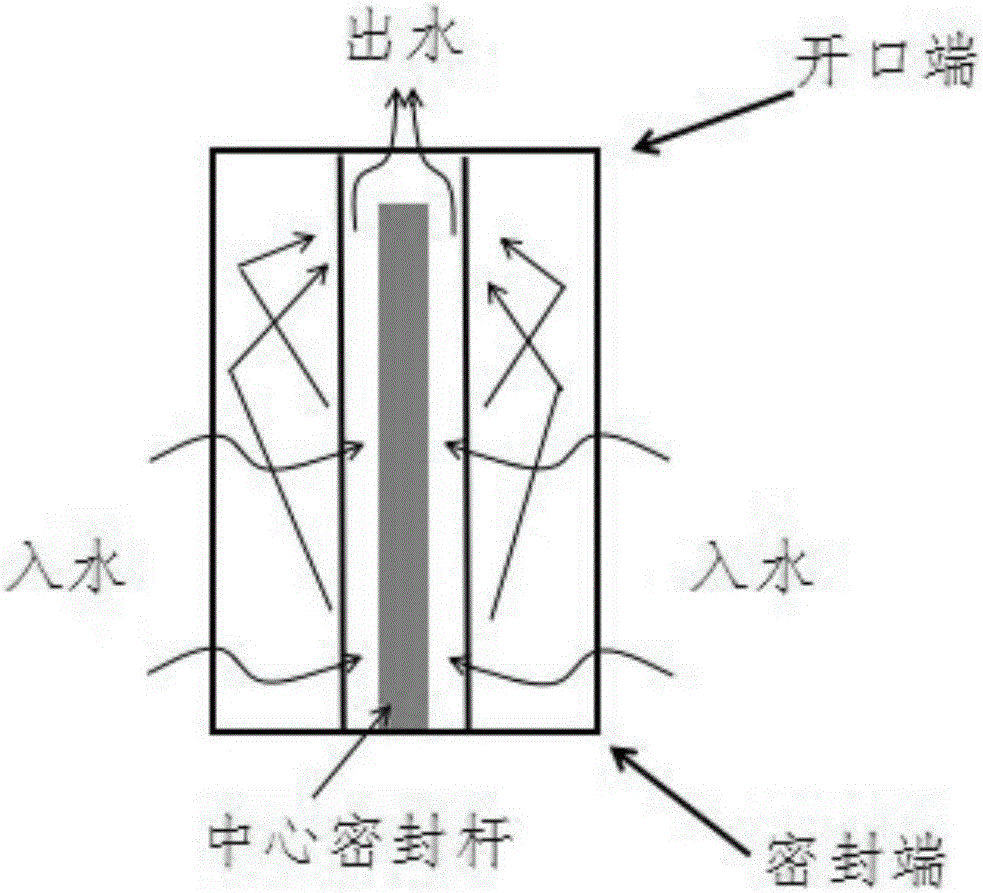

[0024] Take a cylinder with a diameter of 10mm and a length of 120mm and fix it in a carbon rod, then seal one end of it with the lower end cap, and the other end with the upper end cap, as the water outlet, and record it as sample B1;

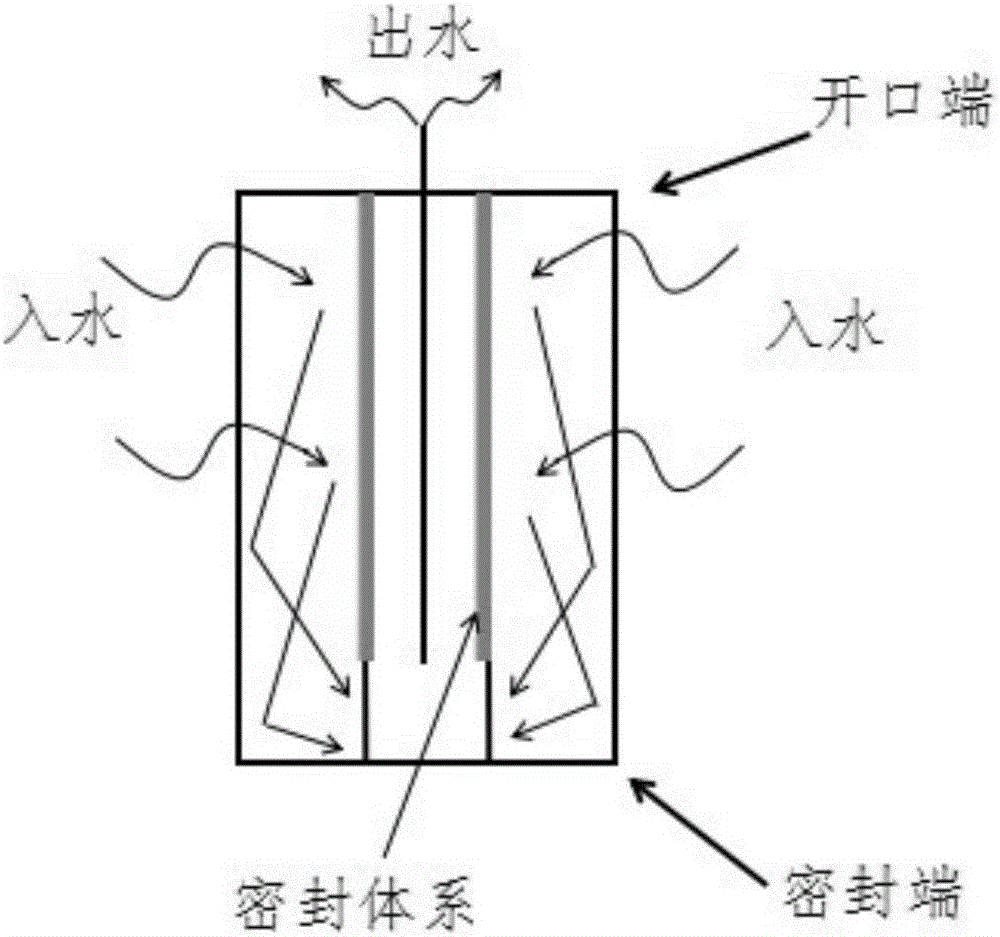

[0025] Seal the inner wall of the carbon rod by 120mm, then seal one end with the lower end cap, and the other end with the upper end cap, as the water outlet, which is recorded as sample C1;

[0026] Take a cylinder with a diameter of 12mm and a length of 150mm and fix it in a carbon rod, then seal one end of it with the low...

Embodiment 2

[0029] Take 5 antibacterial activated carbon rods with an outer diameter of 45mm, an inner diameter of 20mm, and a length of 180mm (produced by Huizhou Yinjia Environmental Protection Technology Co., Ltd.), and carry out different packaging according to the following methods:

[0030] Carry out ordinary packaging of the carbon rod, one end is sealed with the lower end cap, and the other end is sealed with the upper end cap, which is used as the water outlet, which is recorded as sample A2;

[0031] Take a cylinder with a diameter of 10mm and a length of 120mm and fix it in a carbon rod, then seal one end of it with the lower end cap, and the other end with the upper end cap, as the water outlet, and record it as sample B2;

[0032] Seal the inner wall of the carbon rod by 120mm, then seal one end with the lower end cap, and the other end with the upper end cap, as the water outlet, which is recorded as sample C2;

[0033] Take a cylinder with a diameter of 12mm and a length of...

Embodiment 3

[0036] Take 5 pieces of scale-inhibiting carbon membranes with an outer diameter of 45mm, an inner diameter of 20mm, and a length of 180mm (produced by Huizhou Yinjia Environmental Protection Technology Co., Ltd.), and carry out different packaging according to the following methods:

[0037] Carry out ordinary packaging of the carbon rod, one end is sealed with the lower end cap, and the other end is sealed with the upper end cap, which is used as the water outlet, which is recorded as sample A3;

[0038] Take a cylinder with a diameter of 10mm and a length of 120mm and fix it in a carbon rod, then seal one end of it with the lower end cap, and the other end with the upper end cap, as the water outlet, and record it as sample B3;

[0039] Seal the inner wall of the carbon rod by 120mm, then seal one end with the lower end cap, and the other end with the upper end cap, as the water outlet, which is recorded as sample C3;

[0040] Take a cylinder with a diameter of 12mm and a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com