Automatic cleaning equipment

A technology for automatic cleaning and equipment, applied in cleaning methods and utensils, cleaning methods using tools, chemical instruments and methods, etc., can solve the problems of increasing production costs and bulky cleaning devices, and achieve low production costs and good cleaning effects , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0016] The application principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

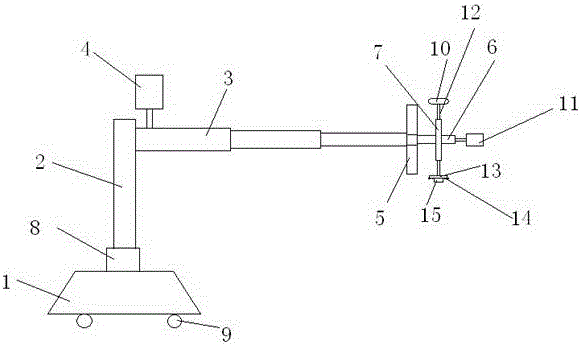

[0017] Such as figure 1 As shown, a kind of automatic cleaning equipment comprises base 1, column 2, telescopic bar 3, cleaning device; Described column 2 is installed on the base, and described telescopic bar 3 is driven by first motor 4, and one end thereof Link to each other with the top of column 2; Described cleaning device comprises first supporting plate 5, rotating shaft 6, runner 7, spray washing head, cleaning head, air dryer 10, one side of first supporting plate 5 and tele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com