Lubrication system for hot rolling of vertical roller mill plate blank

A lubrication system and vertical roll mill technology, applied in the field of lubrication systems, can solve the problems of affecting the quality of the edge, frequent roll changes, and increased surface wear of vertical rolls, etc., so as to improve the surface quality of products, reduce power consumption, and reduce friction coefficient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

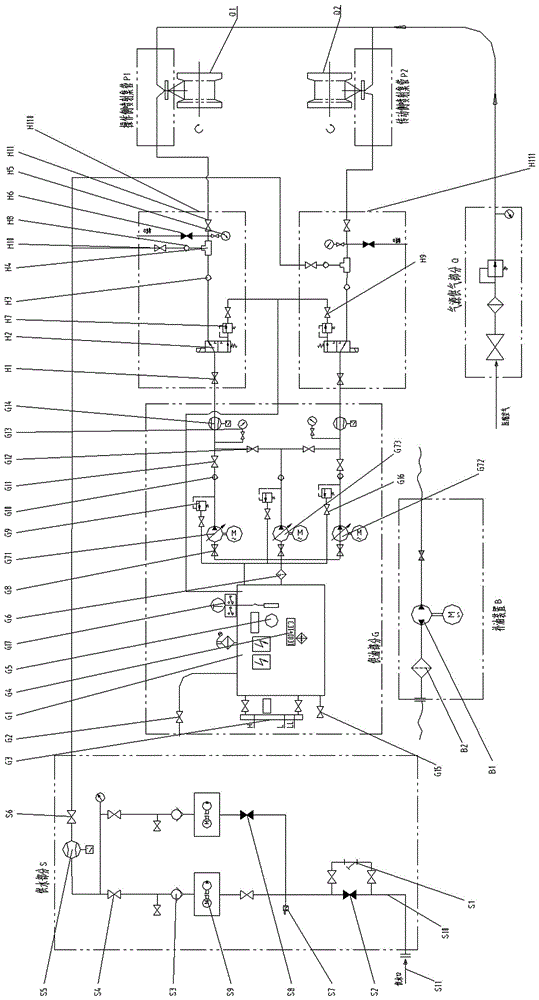

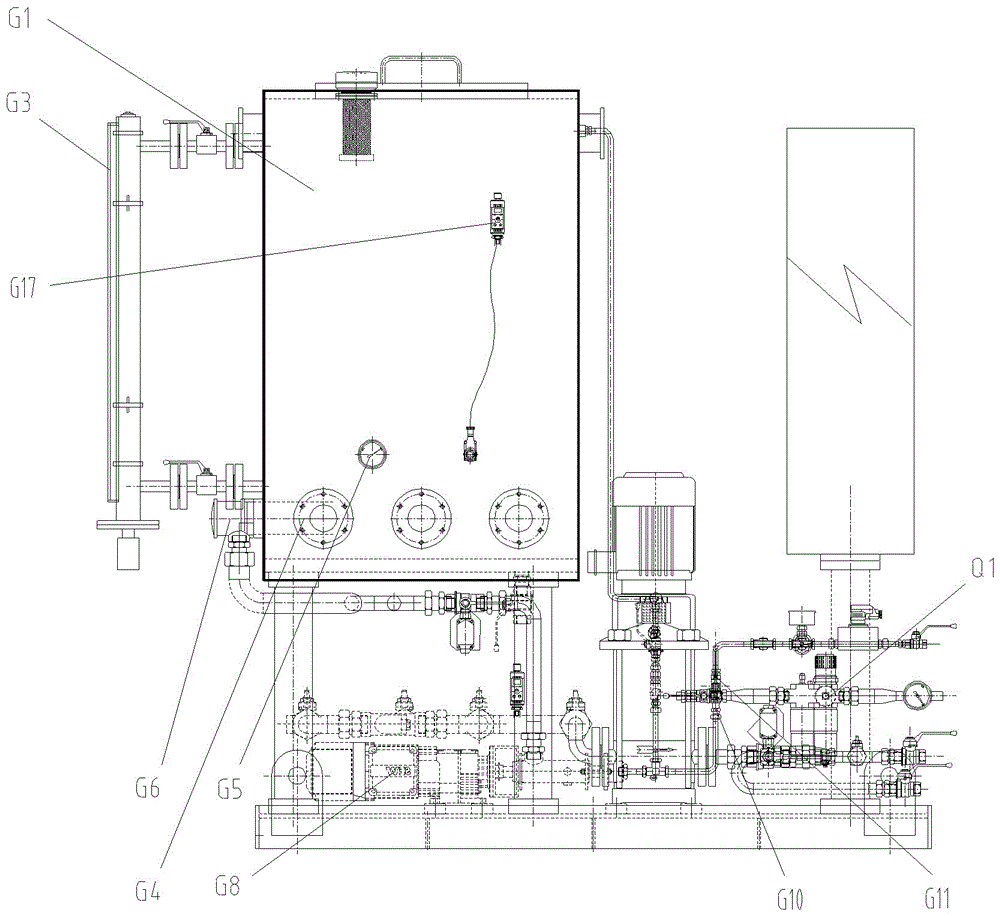

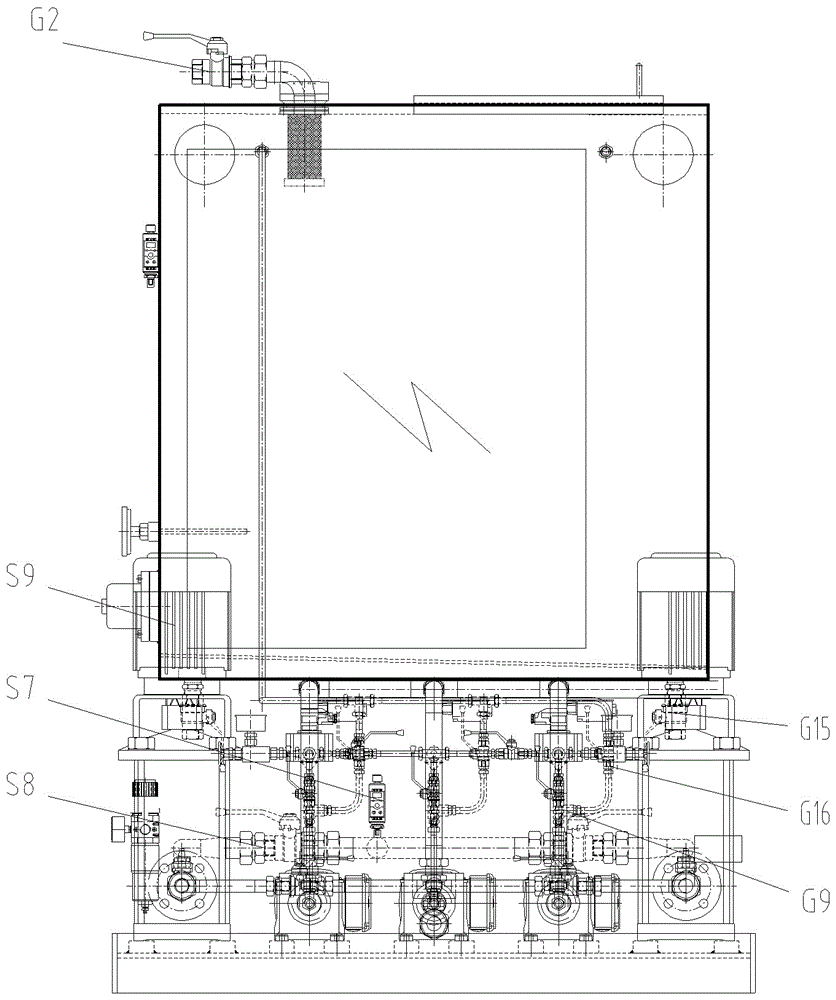

[0041] Such as figure 1 As shown, the lubrication system for hot slab rolling of the vertical roller mill of the present invention includes an oil supply part G, a water supply part S, a mixing control part, a spray header device, an air supply Q and an oil supply device B , the mixing control part is connected with the injection header device, the centrifugal water pump S9 of the water supply part S sends water to the mixer H4 of the mixing control part, and the metering pump of the oil supply part G sends the oil in the oil storage tank G1 to the mixing control part In the mixer H4, the oil replenishment device B is used to replenish lubricatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com