Position compensation device and method in annular rolled piece machining process

A technology of compensation device and compensation method, which is applied in the direction of rolling mill control device, metal processing equipment, metal rolling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

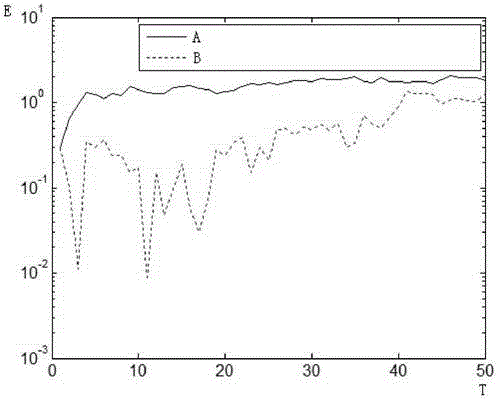

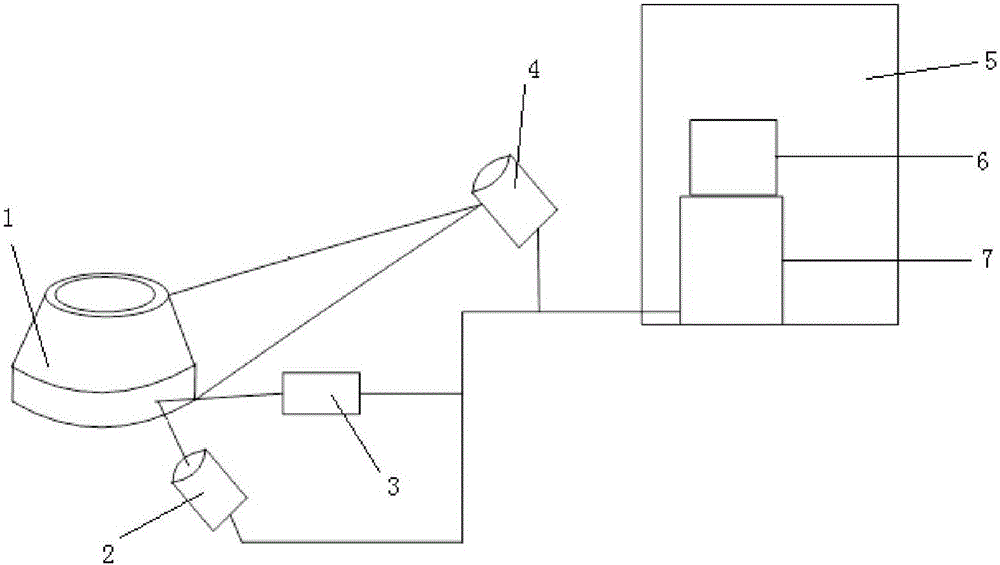

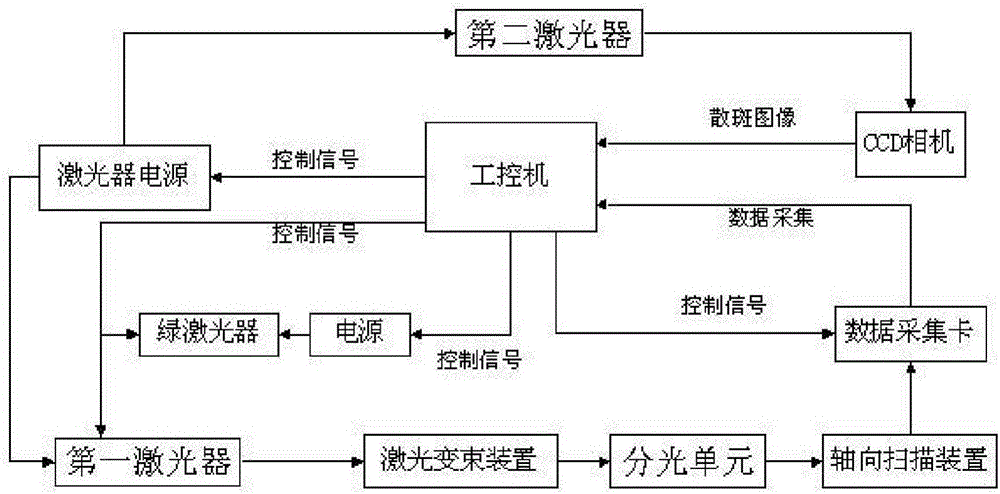

[0047] figure 1 Shown is the position compensation device of the ring rolling piece of the present invention, which uses a laser to detect the size of the ring rolling piece online, including: a laser scanning unit 4, which collects the data of the ring rolling piece 1 during the rolling process; laser speckle imaging A unit, which is synchronized with the laser scanning unit 4, forms a speckle image on the surface of the ring rolling piece 1; and a control unit 7, which controls the laser scanning unit 4 and the laser speckle imaging unit, based on the data collected by the laser scanning unit 4 and the speckle image formed by the laser speckle imaging unit to calculate the radius compensation amount of the ring rolling piece 1 . Since the radius of the ring rolling piece 1 gradually increases during the rolling process, it is neces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com