3D printing method of low melting point metal fused deposition based on continuous fiber pulling

A low-melting-point metal, continuous fiber technology, applied in the field of metal 3D printing, can solve the problems of difficult to form fine structures, large droplet volume, restricted development space, etc., to avoid internal defects, improve mechanical properties and functionality. , the effect of improving print resolution and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings.

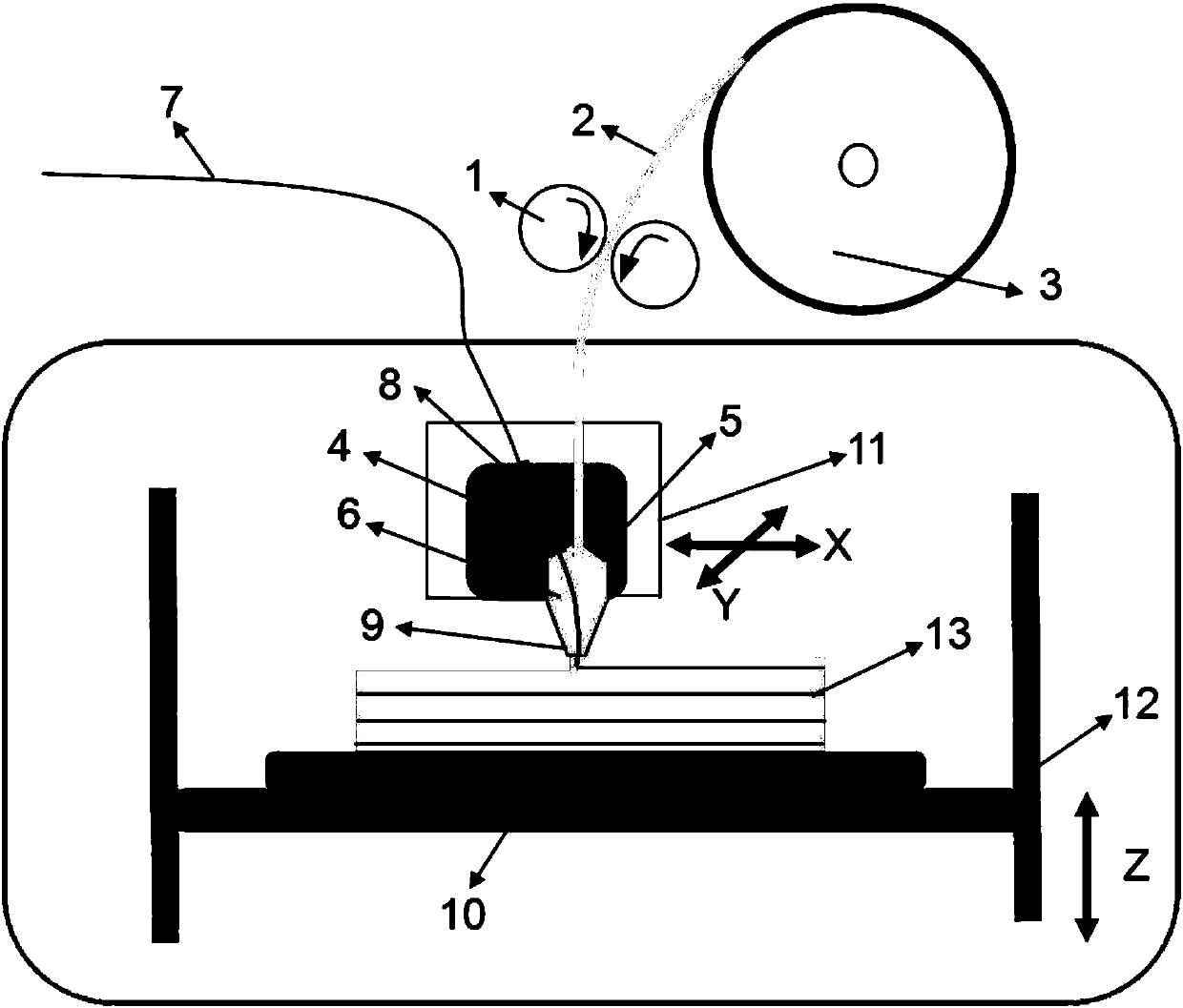

[0018] 1) Refer to figure 1 , the wire feed roller 1 pulls the low-melting point metal wire 2 out of the wire tray 3, and feeds it into the 3D printing head 4 connected to the XY mechanical movement mechanism 11, and melts it in the melting chamber 5 of the 3D printing head 4 Liquid metal 6, the low-melting point metal wire 2 is Bi, Sn, Pb or In-based alloy; at the same time, the continuous fiber filament 7 enters the melting chamber 5 through the microporous channel 8 of the 3D printing head 4, the described Continuous fiber filament 7 is carbon fiber, glass fiber, metal fiber or organic synthetic fiber;

[0019] 2) The continuous fiber filament 7 in the melting chamber 5 is infiltrated with the liquid metal 6, and is extruded from the nozzle 9 of the 3D printing head 4 together. Under the traction of the continuous fiber filament 7, the liquid metal 6 does...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com