Numerically-controlled finish-milling device and finish-milling method for steel rail weld joints

A rail and precision milling technology, applied to milling machine equipment, milling machine equipment details, metal processing equipment, etc., can solve problems such as high labor intensity, processing error scrap rate, and inconvenient replacement of faulty maintenance parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

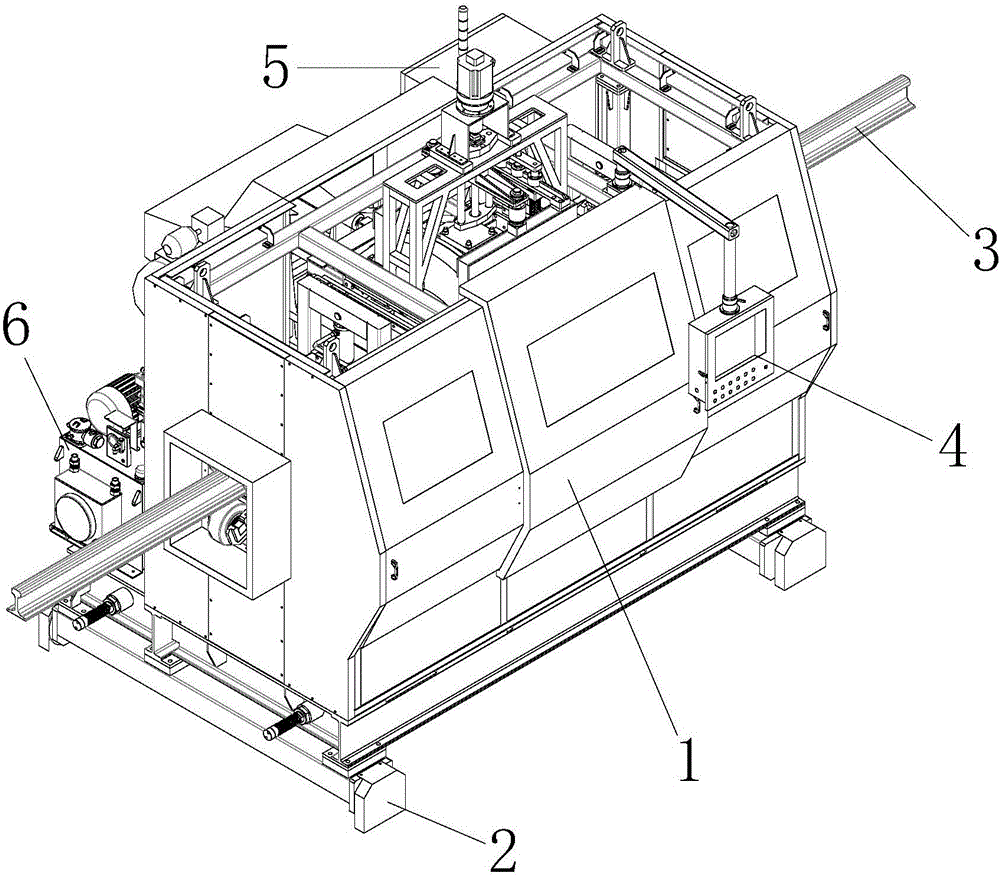

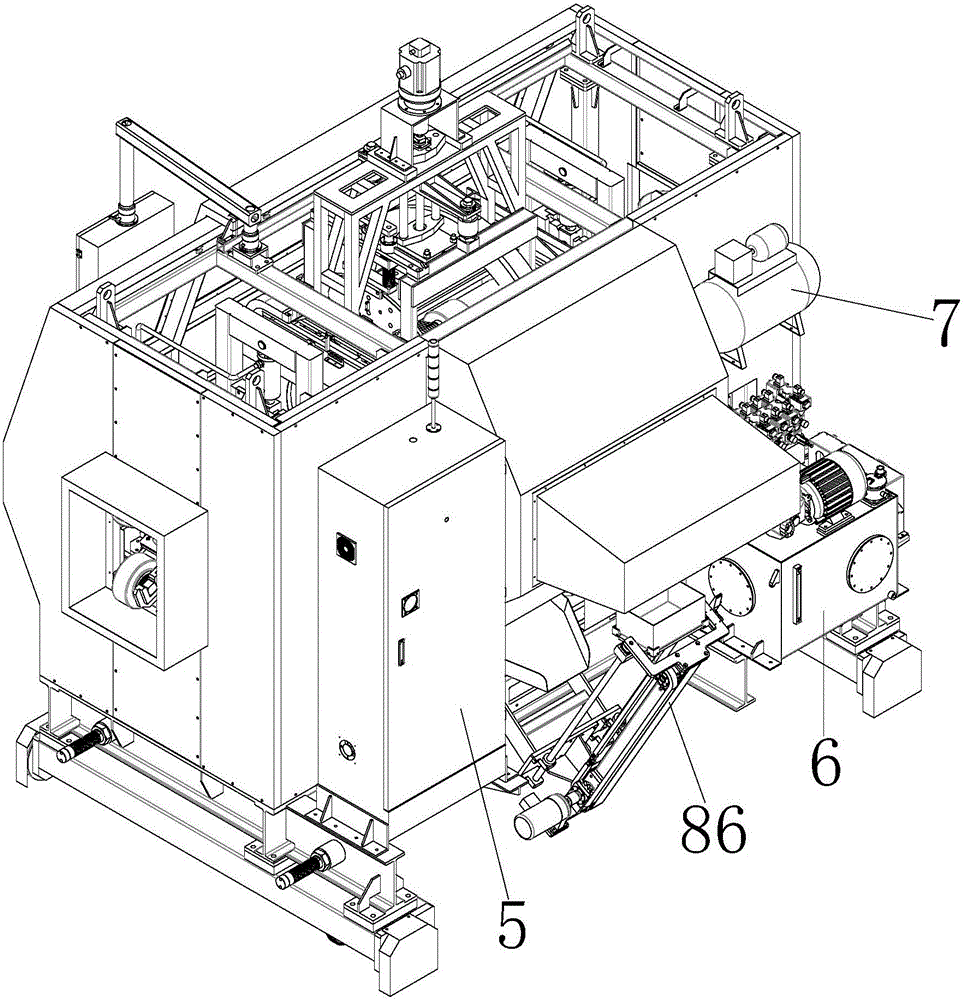

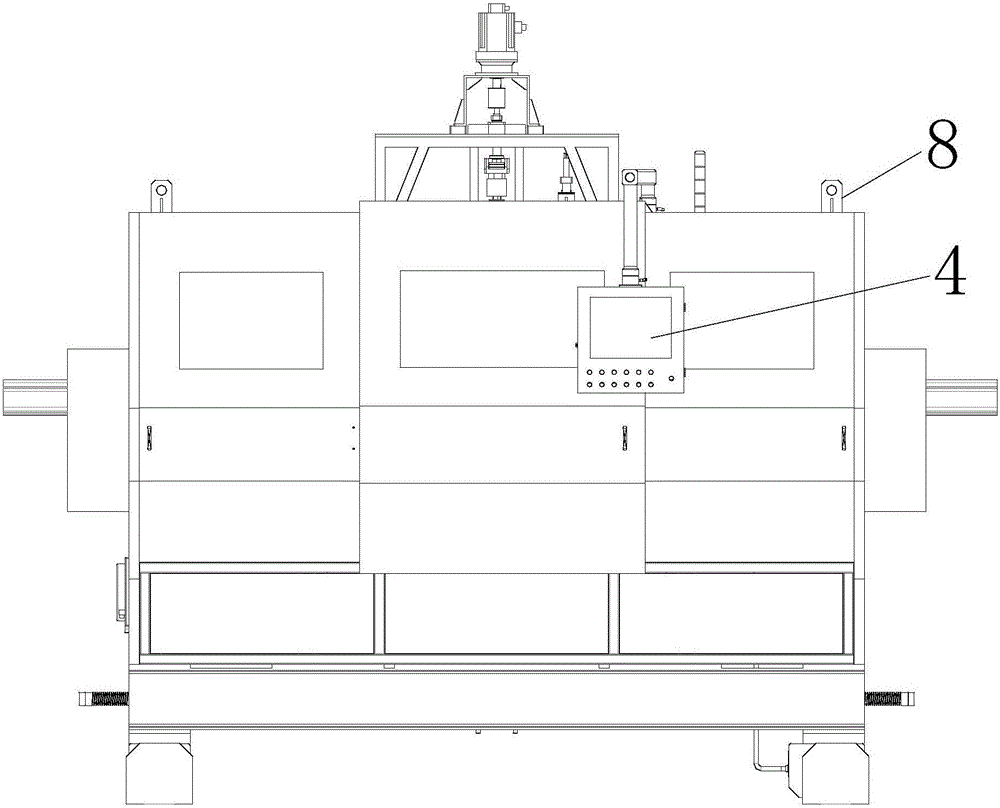

[0083] Embodiment 1: as Figure 1-5 As shown, the present invention provides a rail weld numerical control precision milling equipment, the equipment is assembled from the following major parts, the installation and connection of the equipment mainly adopts the fastening method of screws and positioning pins, and the external three-phase power supply required by the equipment 380V; specifically includes: the base walking assembly 2 that controls the left and right movement of the equipment, the shell door assembly 1 set on the base walking assembly 2, two sets of rail clamping mechanisms 9 and the CNC precision milling mechanism 10. Among them: the shell door assembly 1 is equipped with an operation box assembly 4, an electric cabinet 5, a hydraulic system 6 and an air compressor 7, the operation box assembly 4 is connected with the electric cabinet 5, and the operation box assembly 4 is the operating system of the equipment, which can realize The human-machine interface only ...

Embodiment 2

[0096] Embodiment 2: as Figure 21-22 As shown, referring to the above-mentioned accompanying drawings at the same time; the present invention provides a finishing milling method of a rail weld CNC finish milling equipment, comprising:

[0097] Part 1: Seam Finding and Rail Positioning and Clamping

[0098] The first step: Start the CNC precision milling equipment for rail welds, the traveling oil motor, the lower compression cylinder, the small horizontal compression cylinder, and the large horizontal positioning cylinder are in the initial state, the vertical servo feed mechanism, the horizontal servo feed mechanism, and the milling cutter The head rotation servo mechanism is at the origin state, and the counterweight cylinder of the counterweight mechanism is ventilated and jacked up without control to retract.

[0099] Step 2: Find the weld: start the walking oil motor, which can manually control the left and right walking interchange, and stop quickly. During this period...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com