Airless tire and automobile

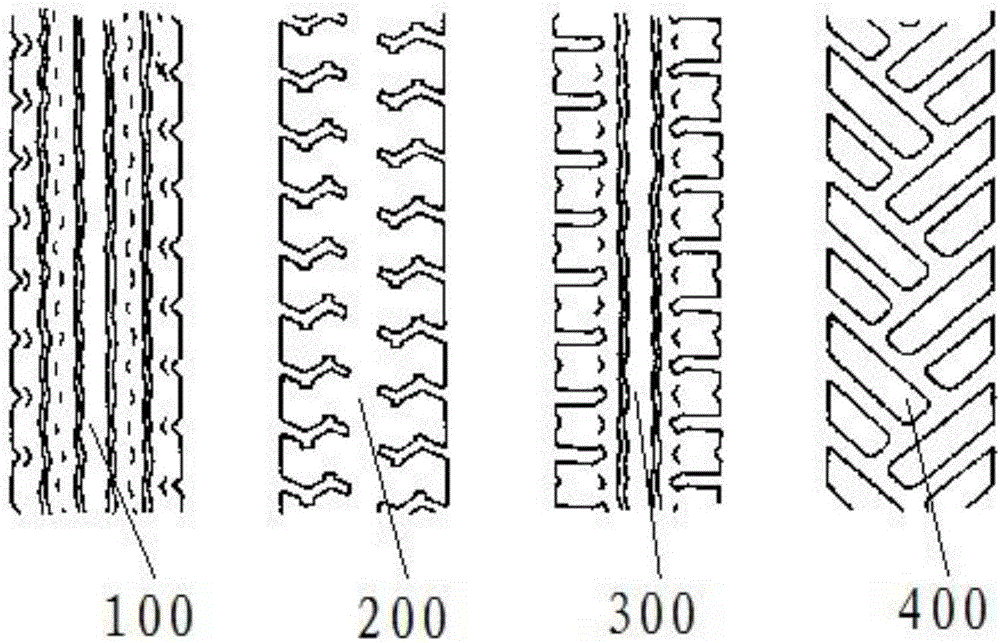

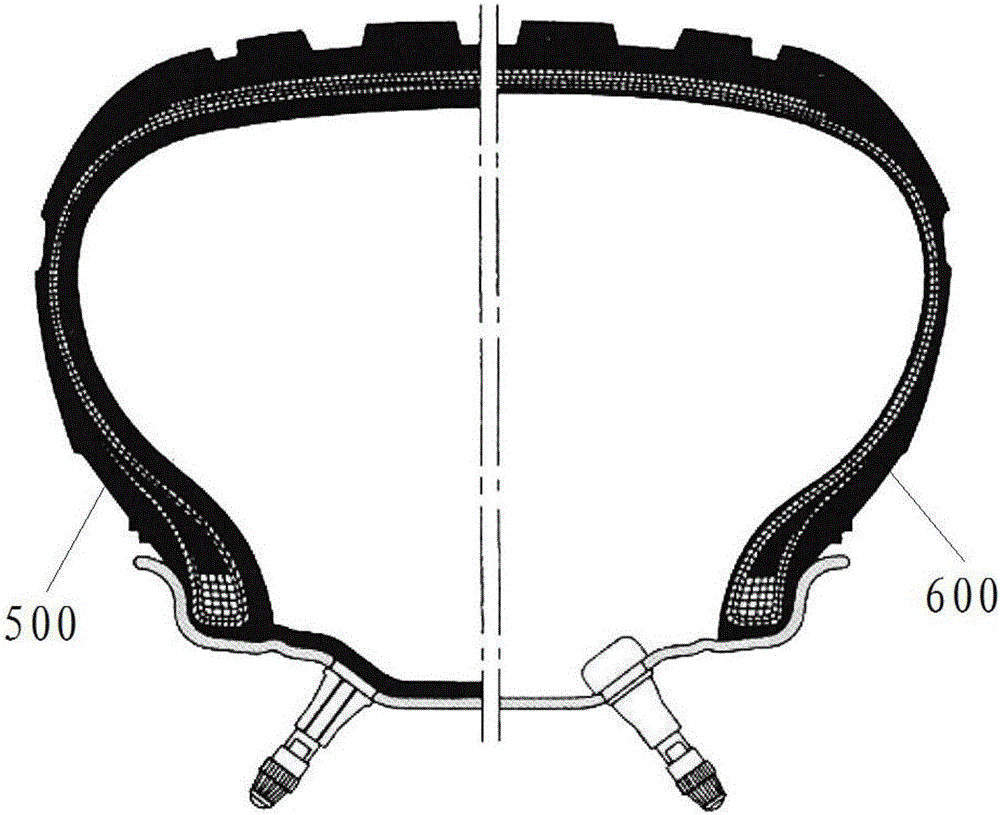

An airless tire and spoke technology, applied in the direction of wheels, vehicle parts, spoked wheels, etc., can solve the problems of poor buffer capacity, braking and acceleration lag, poor vehicle ride comfort, etc., to prevent tire blowout, reduce deformation, The effect of improving the buffer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

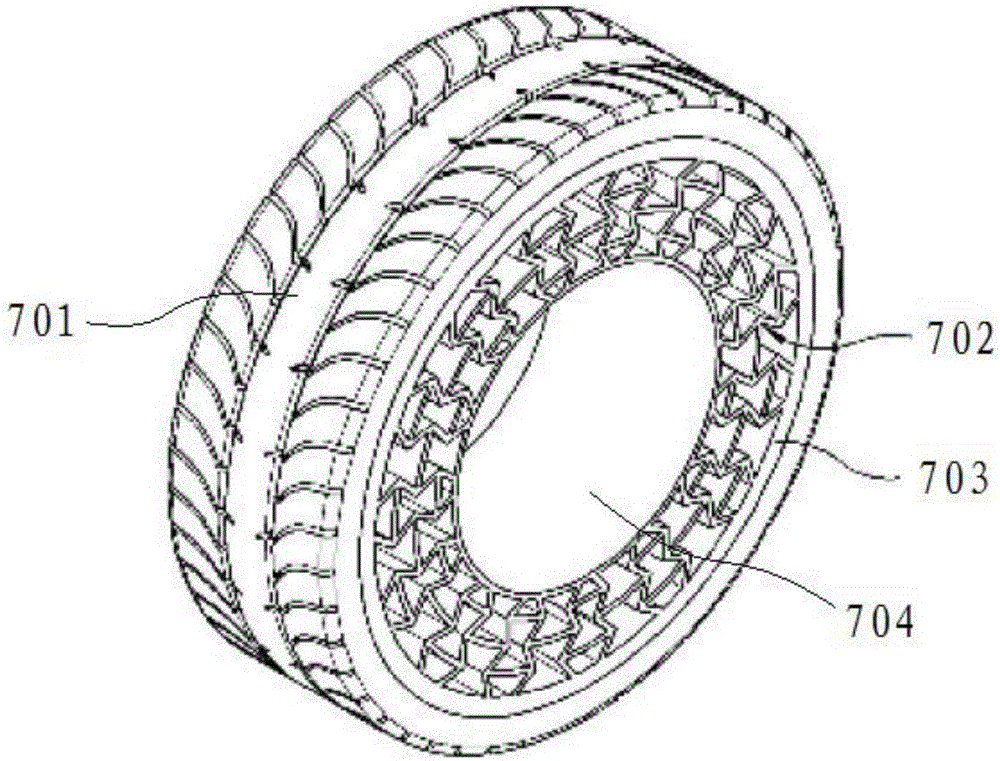

[0036] Embodiments of the present invention: as Figure 4-Figure 9 As shown, an airless tire includes a rubber tread 1 and a spoke 2, the rubber tread 1 is set on the spoke 2, and the spoke 2 is made of non-metallic material; the spoke 2 includes a spoke outer ring 21 , the spoke middle ring 22 and the spoke inner ring 23, the spoke outer ring 21 is fixedly connected with the spoke middle ring 22 through the outer spoke 24, and the spoke middle ring 22 is fixedly connected with the spoke inner ring 23 through the inner spoke 25 . The thickness of the outer spokes 24 is smaller than the thickness of the inner spokes 25 .

[0037] Further, the outer spokes 24 are on the outside of the tangent to the intersection with the spoke inner ring 22, and the inner spokes 25 are on the outside of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com