Widening processing structure of prefabricated channel steel of prefabricated erected simply-supported beam between tunnels and construction method thereof

A technology of simply supported beams and steel structures, which is applied in the erection/assembly of bridges, bridges, bridge construction, etc., which can solve the problems of long construction period for on-site pouring, difficulty in placing materials and construction machines and tools, etc., to simplify on-site construction procedures and shorten The effect of construction period and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in combination with specific embodiments.

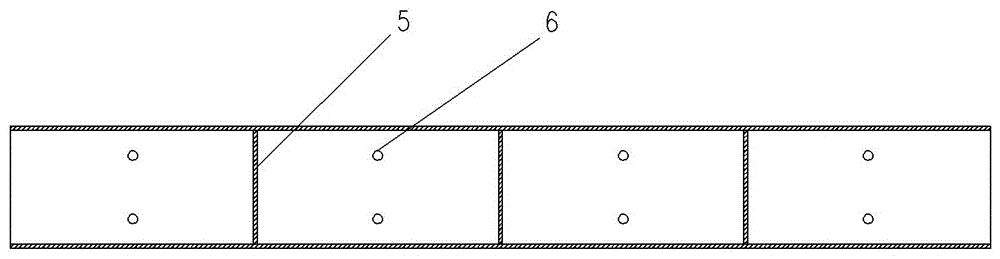

[0028] The present invention relates to a prefabricated and erected simply supported beam prefabricated channel steel widening structure between tunnels, which can be prefabricated and preassembled in the beam yard, and can be disassembled and transported in place by a beam transport vehicle or an integrated machine for transport and frame erection. Connect and pour the later cast-in-place vertical walls, etc. It can greatly simplify the on-site construction process and effectively shorten the construction period, and has obvious economic benefits.

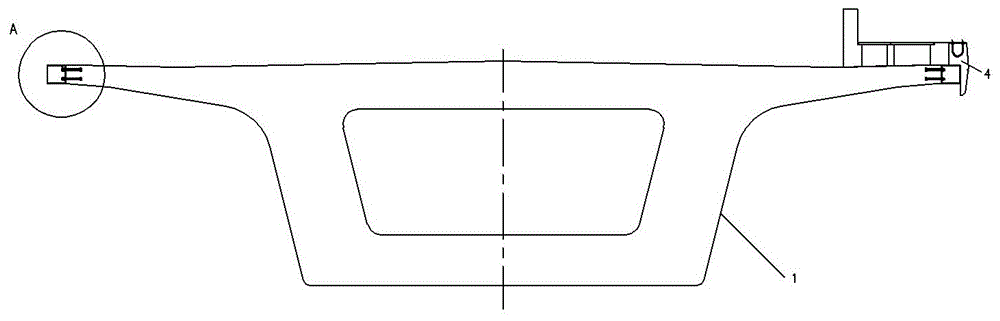

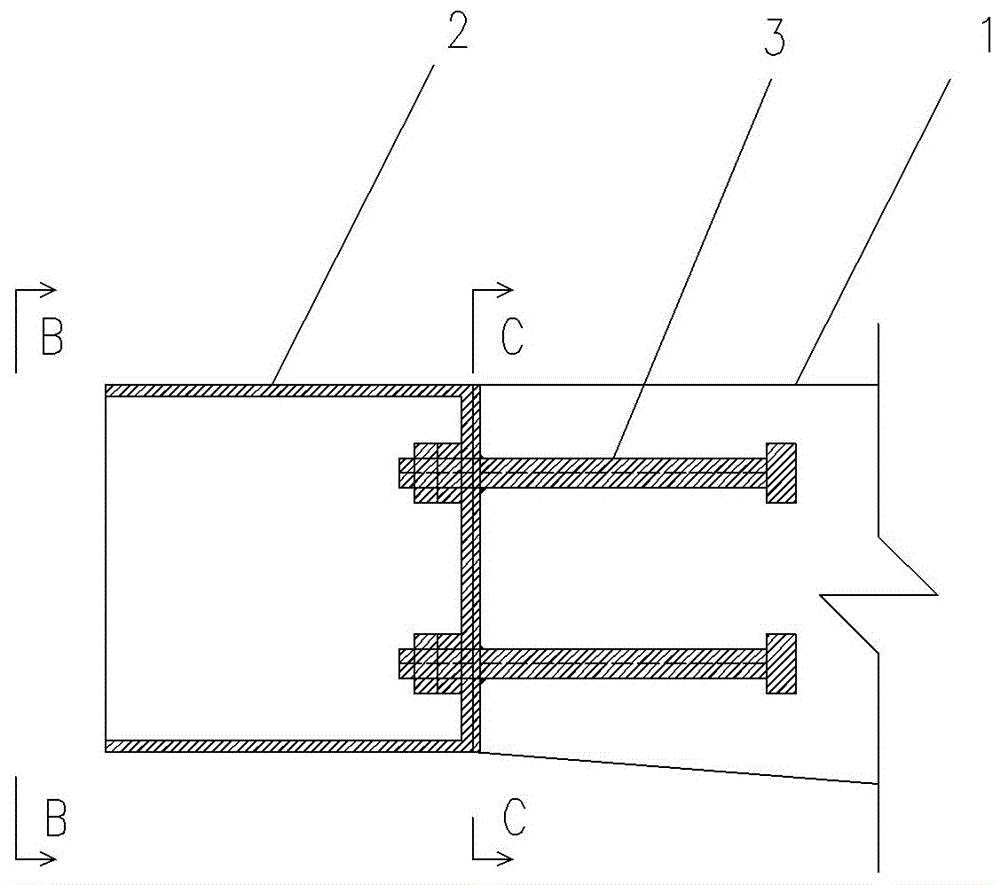

[0029] The present invention makes the prefabricated box girder 1 transition from the original standard beam width of 12.6m to the prefabricated box girder beam width of 12.1m, and the prefabricated channel steel member 2 is arranged outside the flange end face of the prefabricated box girder 1, and the prefabricated channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com