Method and device for forming wall through rolling groove

A roller trough and wall-forming technology, which is applied to sheet pile walls, earth movers/excavators, construction, etc., can solve problems such as difficult control of the quality of consolidated bodies, troubles for engineering designers, and strong ground adaptability, etc., to achieve Excellent performance, novel structure, and strong stratum adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

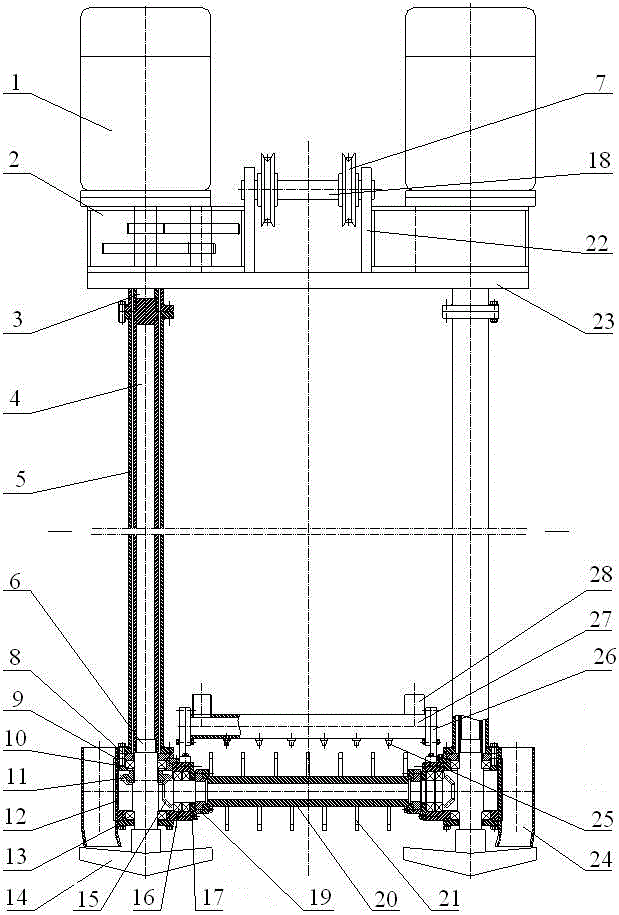

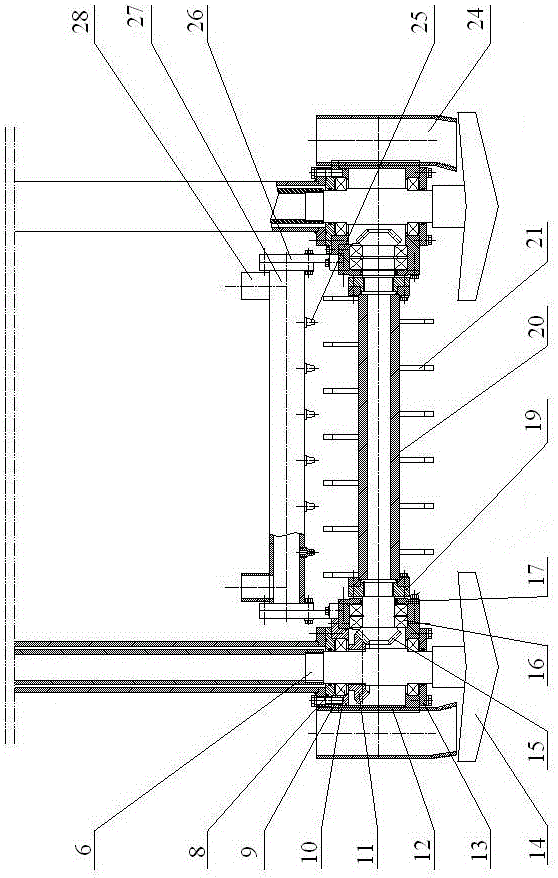

[0030] The structure of the roller groove wall forming device is: the drilling tool system on both sides is fixedly connected with the lifting device, the two ends of the bottom roller system are respectively connected with the drilling tool system, and the flushing pipe assembly is arranged on the upper part of the roller;

[0031] The structure of the drilling tool system is: the motor 1 is connected to the drill pipe 4 through the output shaft 3 of the reduction box 2, the outer tube 5 is located outside the drill pipe 4, the upper end of the transmission shaft 6 is connected to the drill pipe 4, and the lower end is connected to the drill bit 14 , the bearing seat 9 is fixedly connected to the housing 12, the transmission shaft 6 is rotationally connected to the bearing 10, the gear 11 is fixedly connected to the transmission shaft 6, and the upper cover 8 and the lower cover 13 are respectively connected to the housing;

[0032] The structure of the bottom roller system is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com