A two-stage telescopic roadheader combined cutter head with adjustable opening ratio

A telescopic and opening ratio technology, which is applied in mining equipment, earthwork drilling, tunnels, etc., can solve problems such as large overturning moment, poor geological adaptability, and radial unbalanced force of the cutter head, so as to improve the effective service life and economical Considerable performance and the effect of improving geological adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

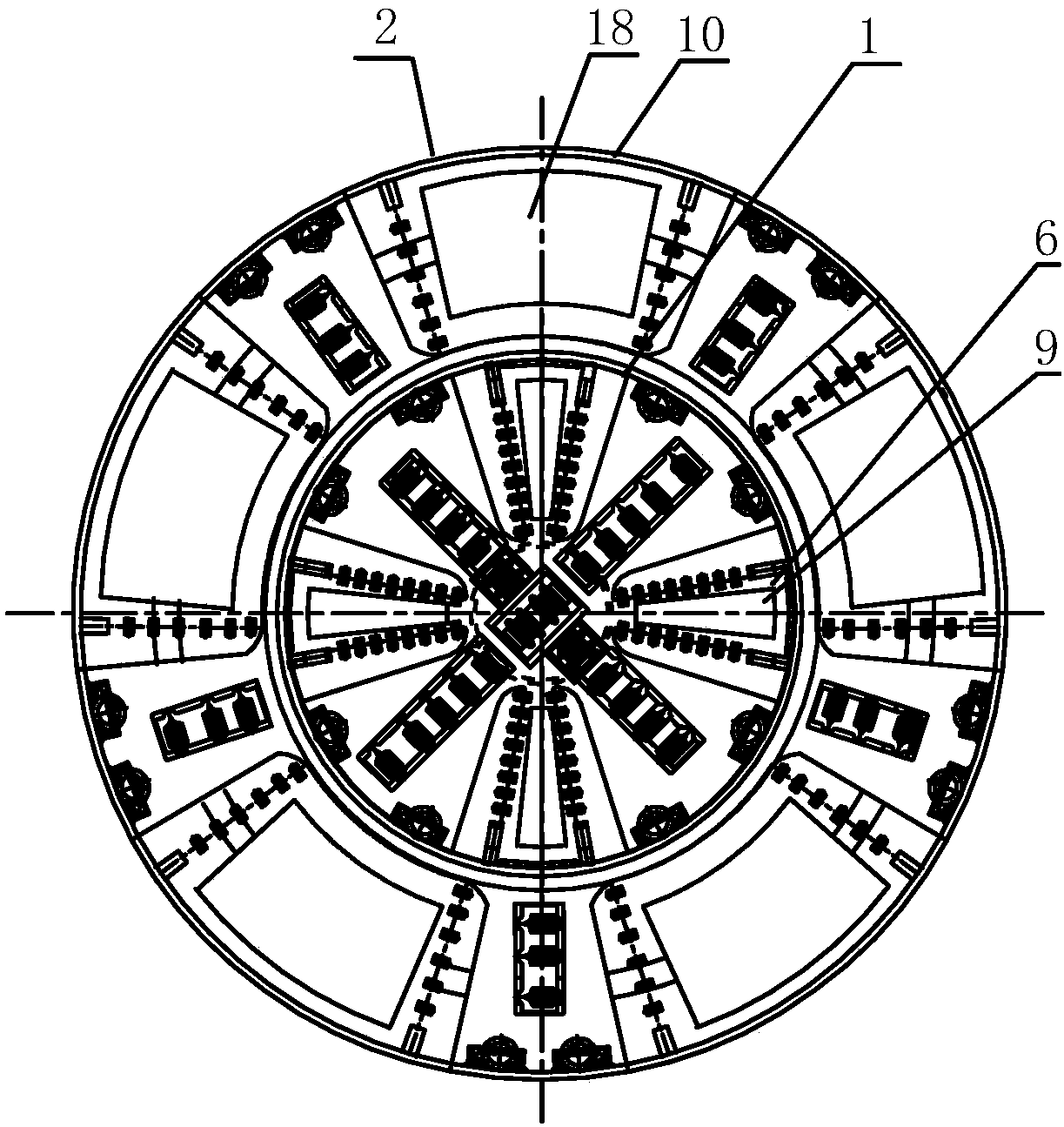

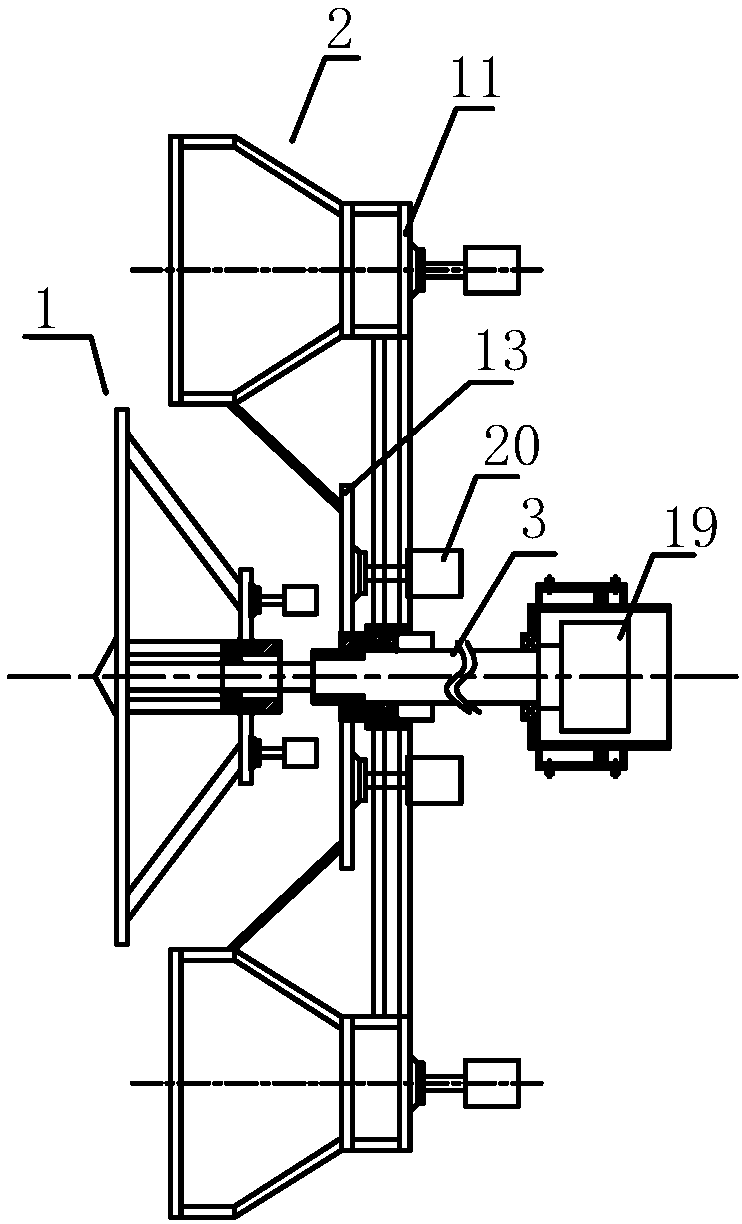

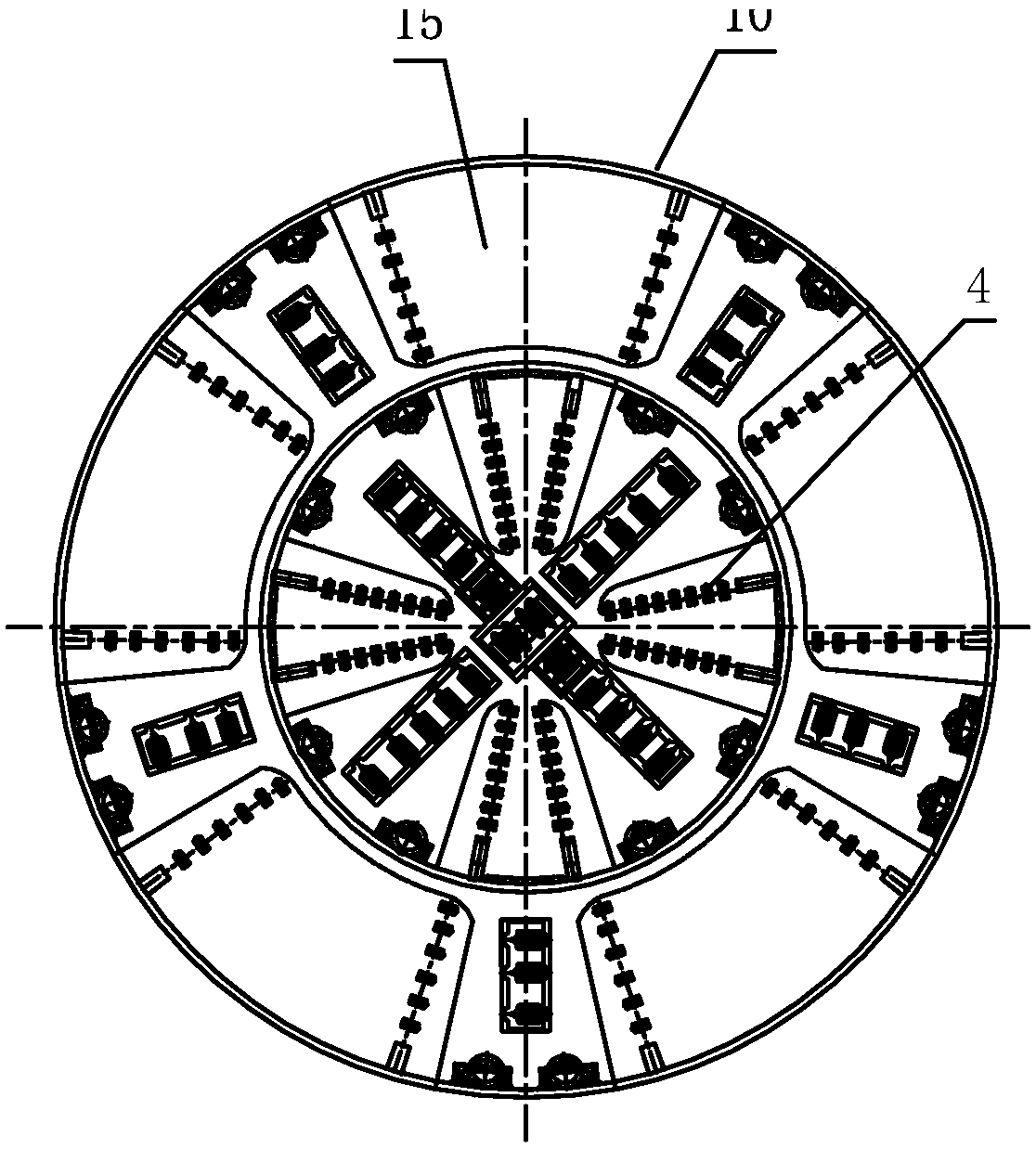

[0029] Embodiment: The specific process of the combined cutter head of the two-stage telescopic roadheader with adjustable opening ratio of the present invention is:

[0030] In this embodiment, the driving device includes a drive shaft 3 driven by a motor, and the axial propulsion device can adopt a hydraulic cylinder system, which includes a main hydraulic cylinder 19 for axially pushing the drive shaft and a plurality of hydraulic cylinders for axially pushing the drive shaft. Cutter telescopic hydraulic cylinders 20 for pushing the cutterheads at all levels and a plurality of sheet disk telescopic hydraulic cylinders 21 for axially pushing the cutterhead webs at all levels, such as figure 2 , Figure 9 ,with Figure 10 shown.

[0031]In the present invention, the first-stage cutter head 4 is connected to the drive shaft 3, and the first-stage cutter head web disc 5 is connected to the drive shaft through splines to realize the coaxial rotation of the first-stage cutter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com