Wind energy collector based on flexible polymer piezoelectric material

A flexible polymer, piezoelectric material technology, applied in wind power generation, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve the problems of high manufacturing cost, high starting wind speed, large size, etc. , to achieve the effect of easy production process, extended service life and good output performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention will be further described below in conjunction with the drawings.

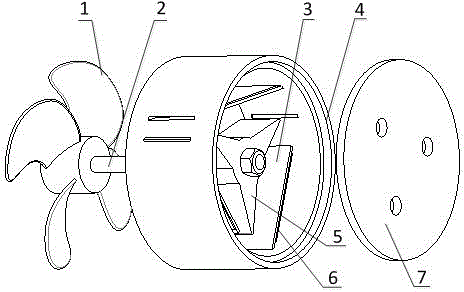

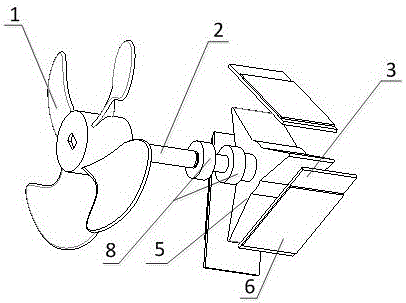

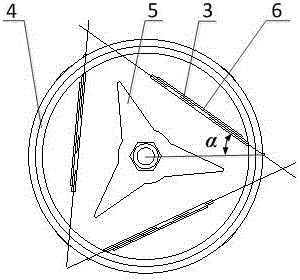

[0019] Such as figure 1 with figure 2 As shown, a wind energy harvester based on a flexible polymer piezoelectric material includes a blade 1, a rotating shaft 2, a flexible material 3, a cylindrical shell 4, a rotating disk 5, a piezoelectric film 6 and a top cover 7, and the rotating shaft 2 passes The bearing 8 is fixed on the cylindrical housing 4 with only one degree of freedom of rotation. One end of the rotating shaft 2 is connected to the blade 1, and the other end is connected to the turntable 5; the flexible material 3 and the piezoelectric film 6 constitute a flexible piezoelectric polymer cantilever beam, A plurality of flexible piezoelectric polymer cantilever beams are uniformly fixed on the cylindrical housing 4, and the top cover 7 is installed at the bottom of the cylindrical housing 4. The wind drives the blade 1 to rotate, and the rotating shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com