Pump for a selective catalytic reduction (SCR) system in vehicles

A technology of SCR system and vehicle, applied in parts of pumping devices for elastic fluids, pumps with flexible working elements, pumps, etc., can solve difficult mixing, no long life, difficult injection of urea solution into exhaust gas flow, etc. problem, achieving long service life, reduced unusable volume, longevity and optimal accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

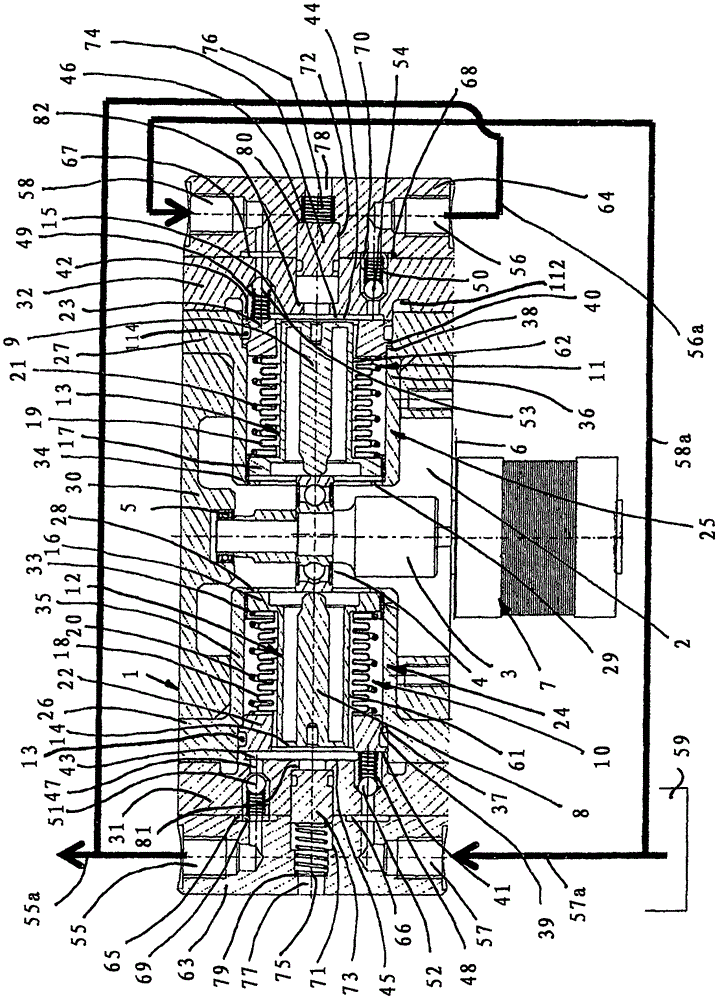

[0043] The described pump is used for SCR (Selective Catalytic Reduction System). With this pump, the urea solution is injected into the exhaust system before the SCR catalytic converter of the diesel vehicle to reduce harmful nitrogen oxides in the exhaust, or to remove it. The urea solution is dosed through a pump or an ejector, so that the nitrogen oxides are reliably removed from the exhaust gas or greatly reduced, so that they do not constitute an impact on the environment.

[0044] according to figure 1 The pump has a housing 1. It has a central drive chamber 2 for the drive shaft 3, which has a fixed eccentric disk 4. The free end of the drive shaft 3 can be rotated in a bearing 5 provided on the inner wall of the housing 1. The drive shaft 3 extends from the drive chamber 2 and from the housing 1 through the mounting plate 6. The motor 7 is connected to the mounting plate 6, which closes the drive chamber 2 to the outside, its motor shaft is the drive shaft 3, and rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com