A kind of construction method of pipeline piercing pool

A construction method and pipeline technology, applied in the direction of pipes, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve the problems of poor appearance of the wall surface, enhance the anti-seepage ability, reduce the production cost, and reduce the leakage of the pool wall. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

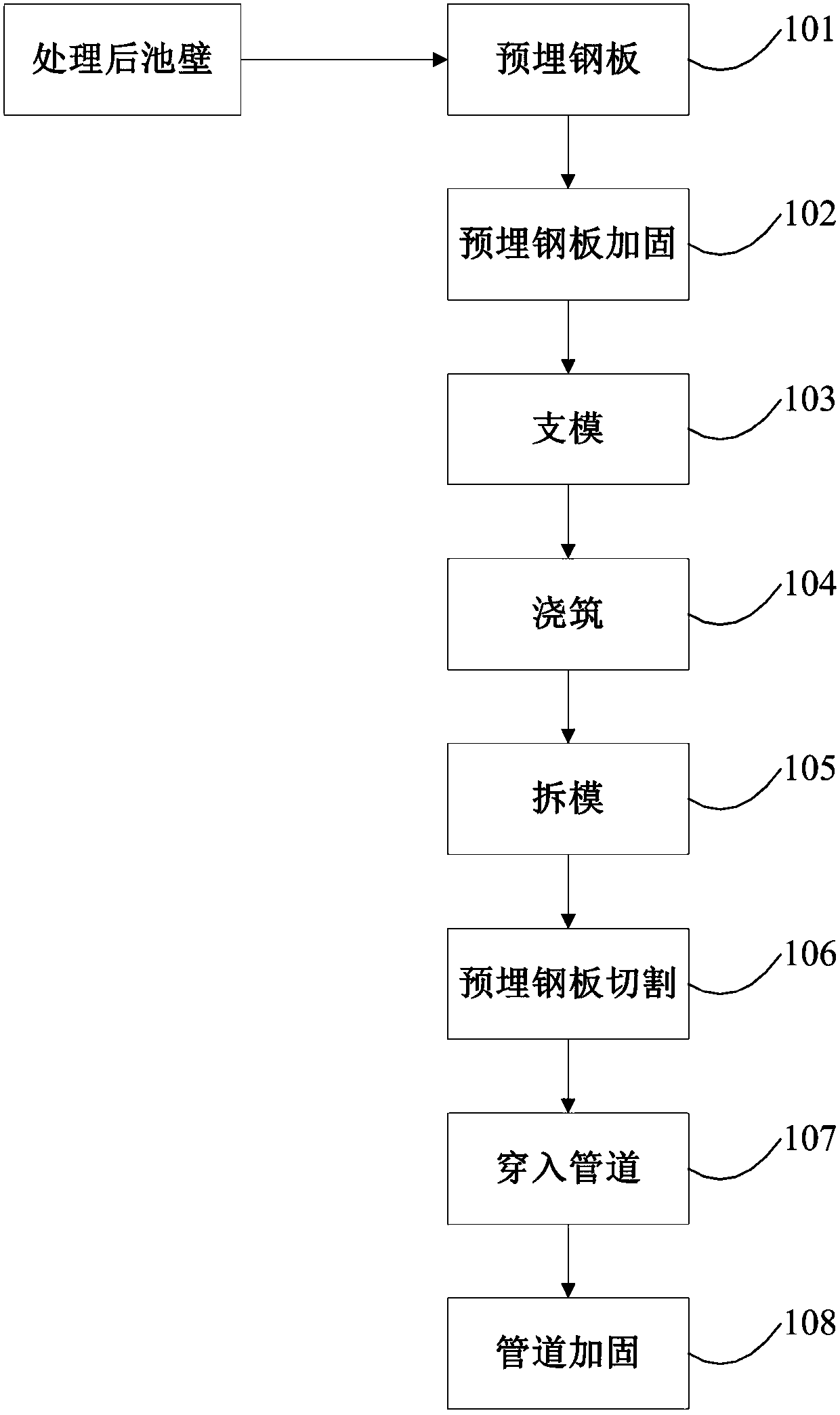

[0026] Such as figure 1 Shown, the present invention provides a kind of construction method of pipeline penetrating pool, it is characterized in that comprising the following steps:

[0027] Step one 101, after the steel bars on the pool wall are bound and rolled, the pool wall of the reserved pipeline is set out and positioned and the steel plate is pre-embedded in the middle of the pool wall along the vertical direction; in the first step, the steel plate can be pre-embedded Its edge is welded to stop the water sheet, which can better prevent leakage. The steel plate in the present invention adopts a square shape, each side is 200mm wider than the pipeline wall, and the thickness is slightly thicker than the pipeline wall thickness. It can be used as a waste steel plate. Because it is embedded in concrete, the steel plate can be derusted.

[0028] Step 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com