Patents

Literature

32results about How to "Effective smoothing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

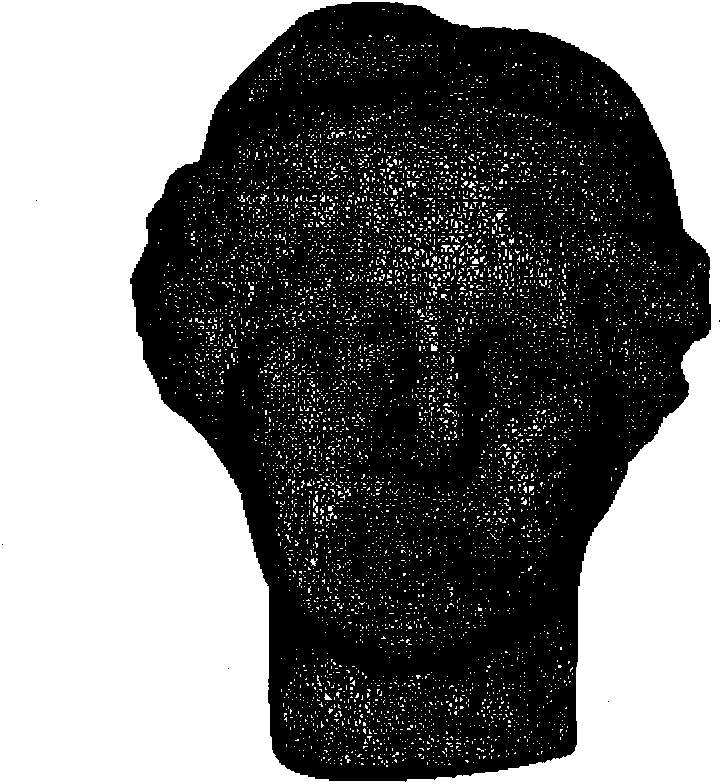

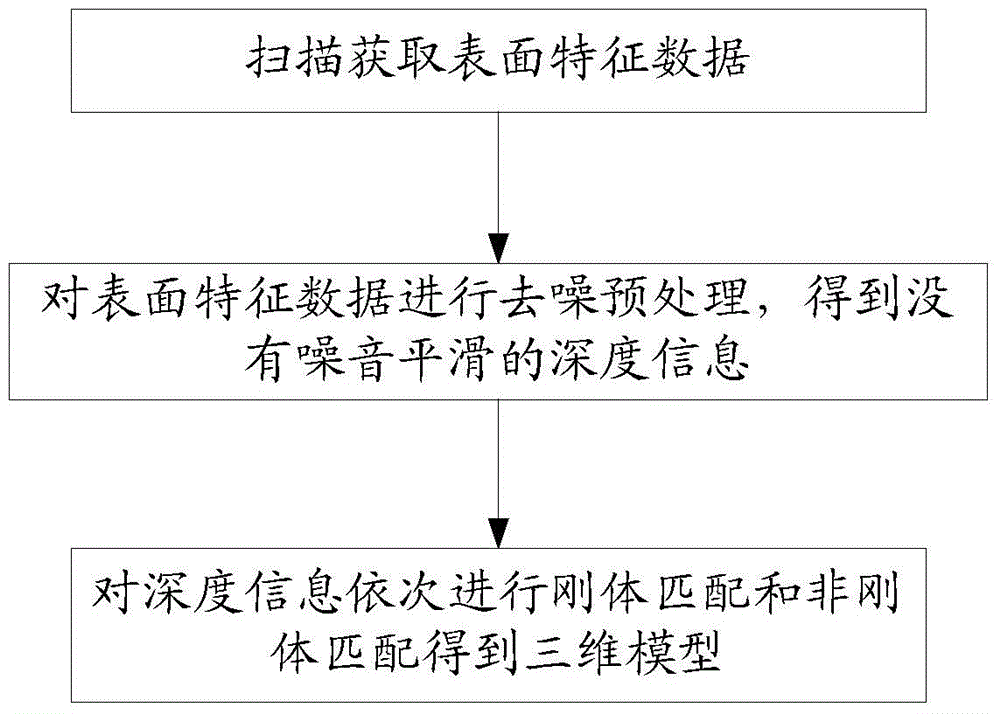

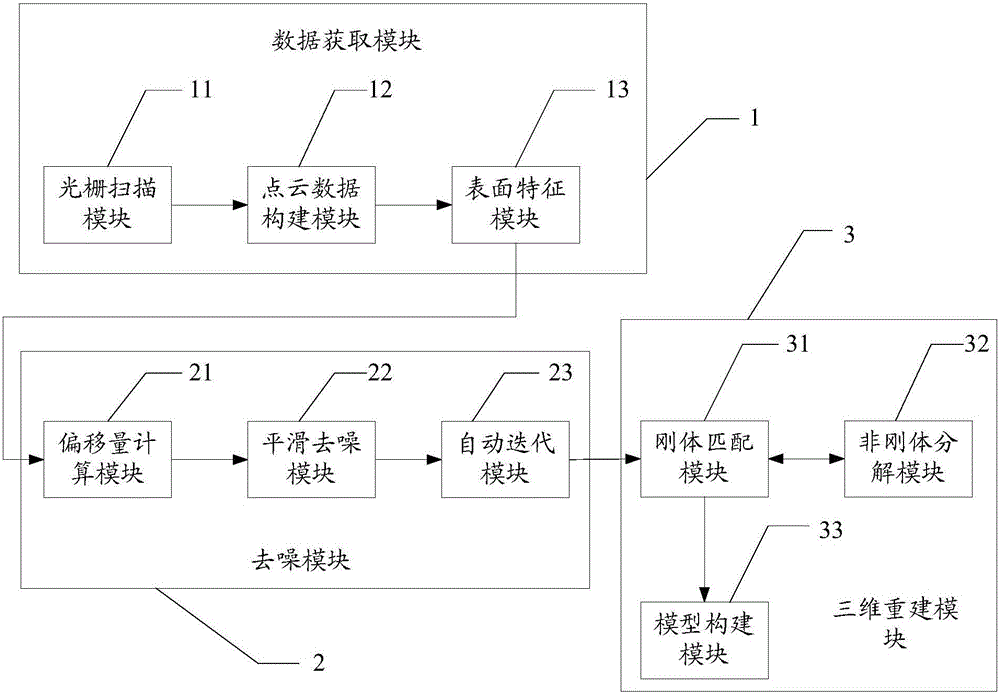

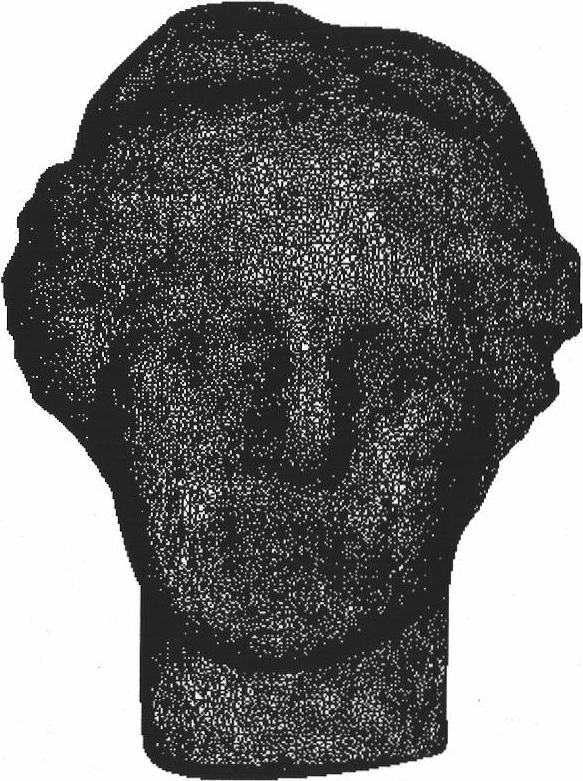

Digital human body three-dimensional reconstruction method and system based on Kinect device

ActiveCN103955963AShort scan timeShort computing time3D modellingReconstruction methodSystem stability

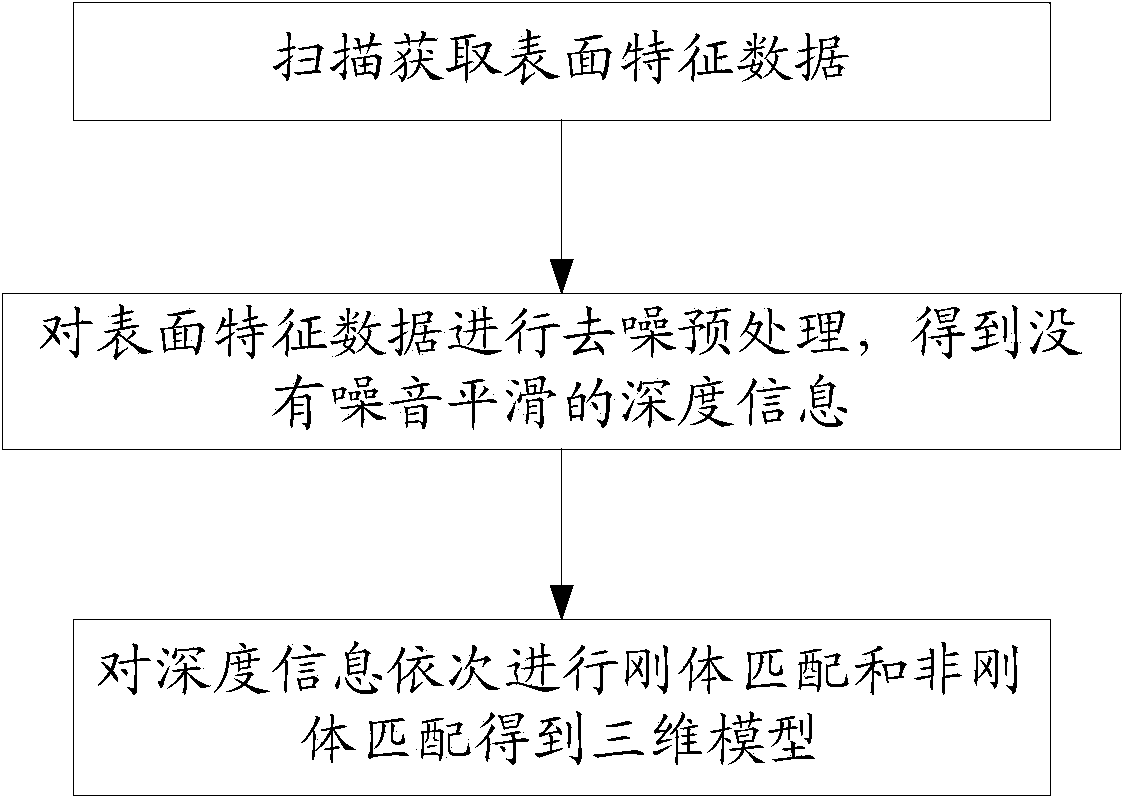

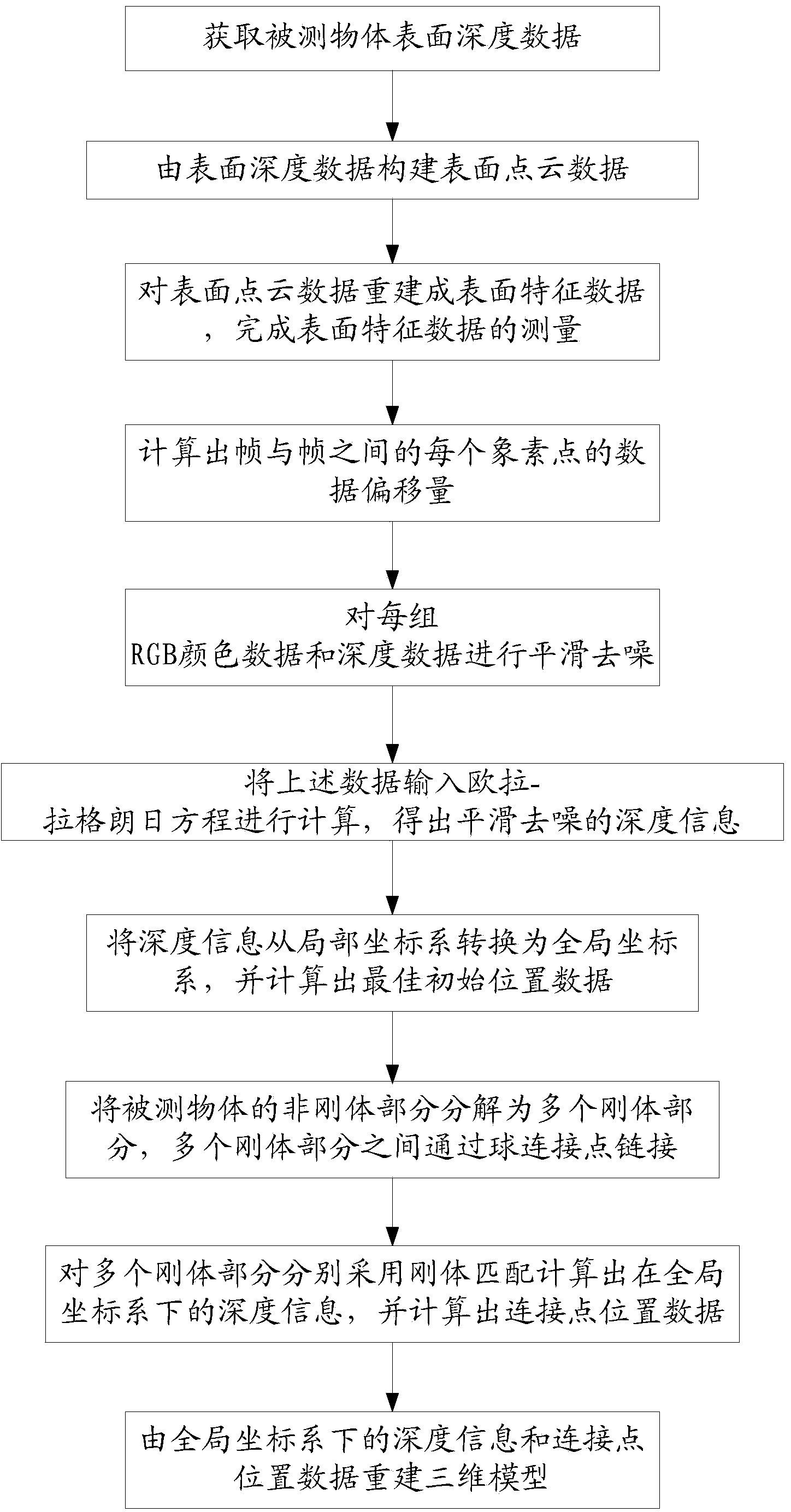

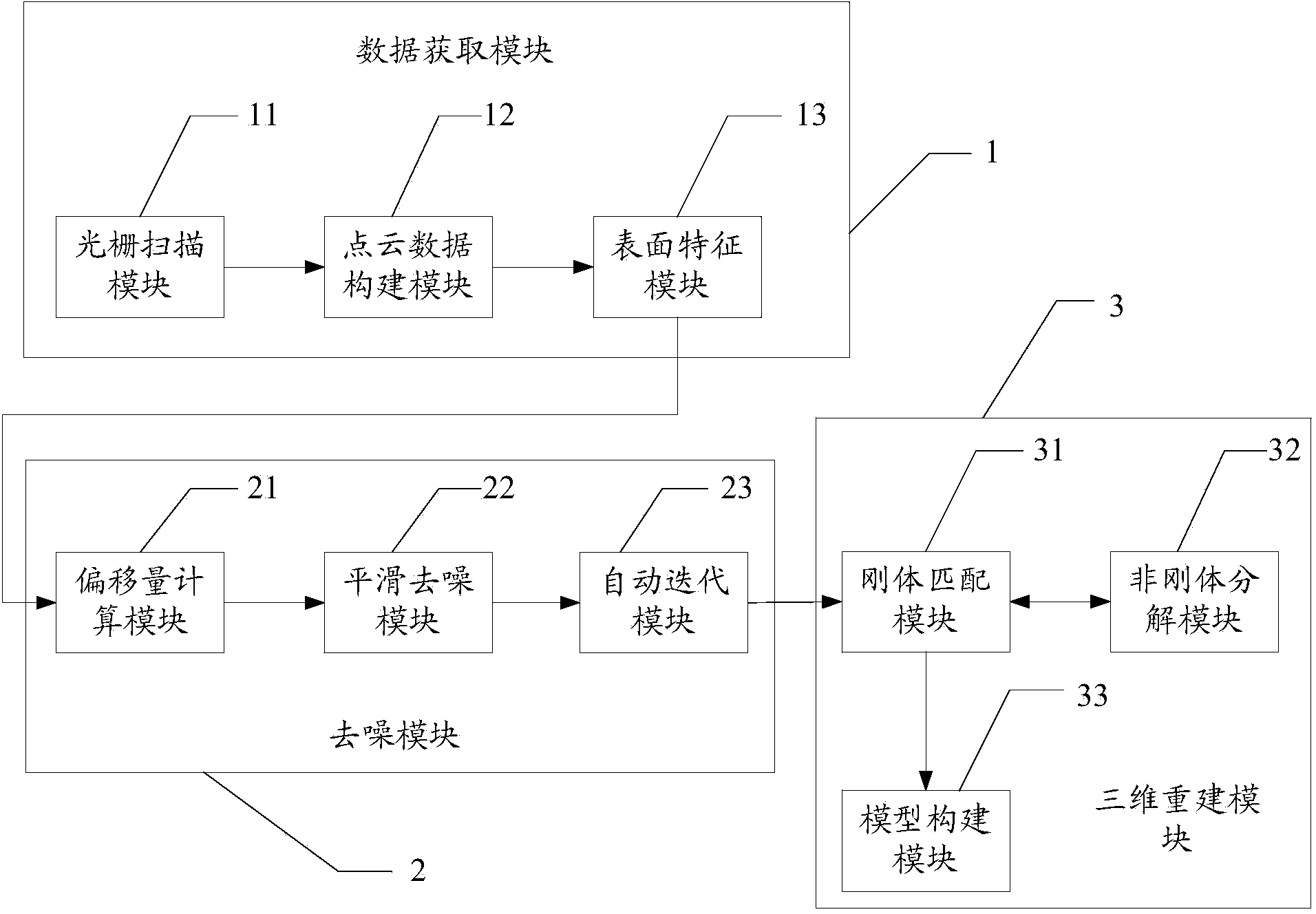

The invention relates to a digital human body three-dimensional reconstruction method based on a Kinect device. The method specifically includes the following steps that firstly, scanning is performed, and surface feature data are obtained; secondly, denoising preprocessing is performed on the surface feature data, and smooth depth information without noise is obtained; thirdly, rigid-body matching and non-rigid-body matching are sequentially performed on the depth information, and a three-dimensional model is obtained. According to the digital human body three-dimensional reconstruction method, the scanning time is short, the scanning process is simple, a hardware device needed in scanning is simple, coordination with other people or instructions learning in advance are not needed in the scanning process, the result geometric accuracy is high, the face structure, the clothes texture structure and the like are quite clear, due to a test, the system stability is high, a one-button mode is adopted in a whole system, a user does not need to set any parameter or change, a final result can be obtained as long as one button is pressed, the operation time is short, and a color map is automatically generated.

Owner:崔岩

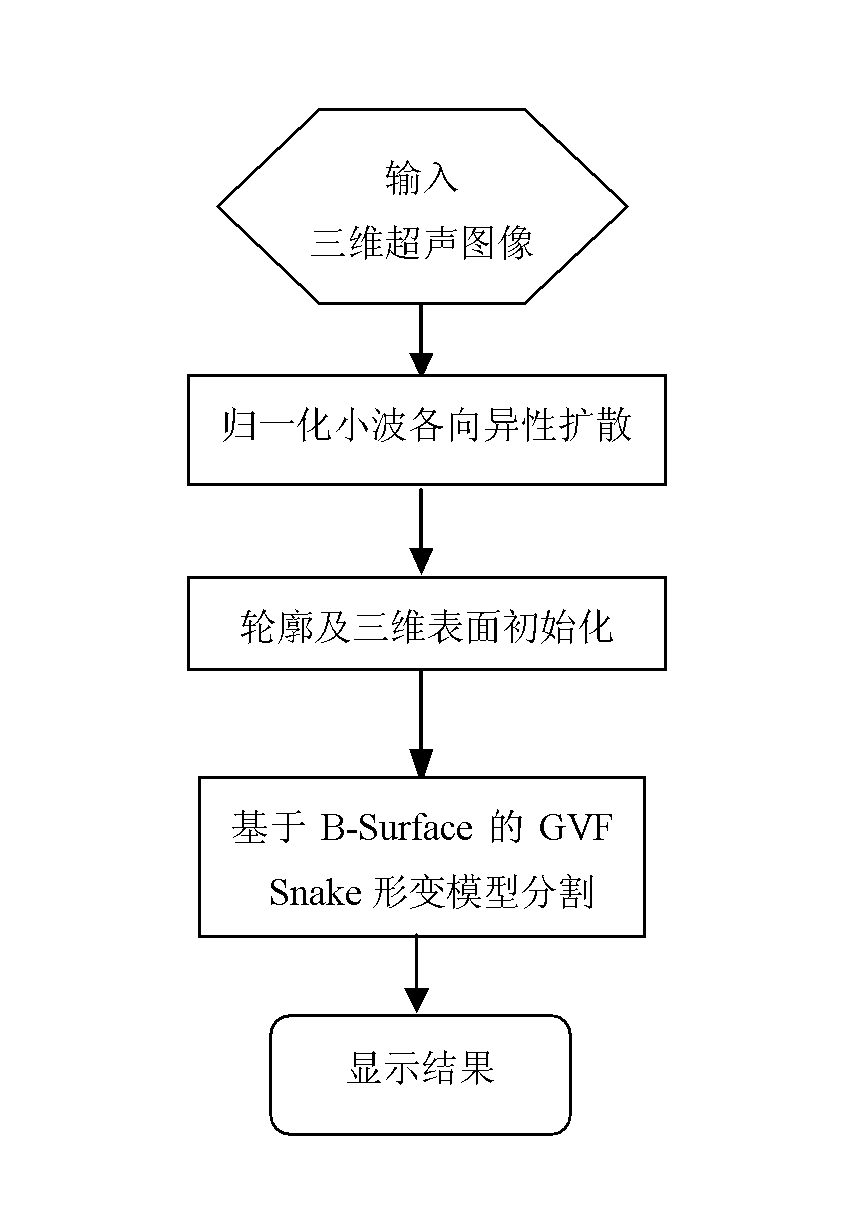

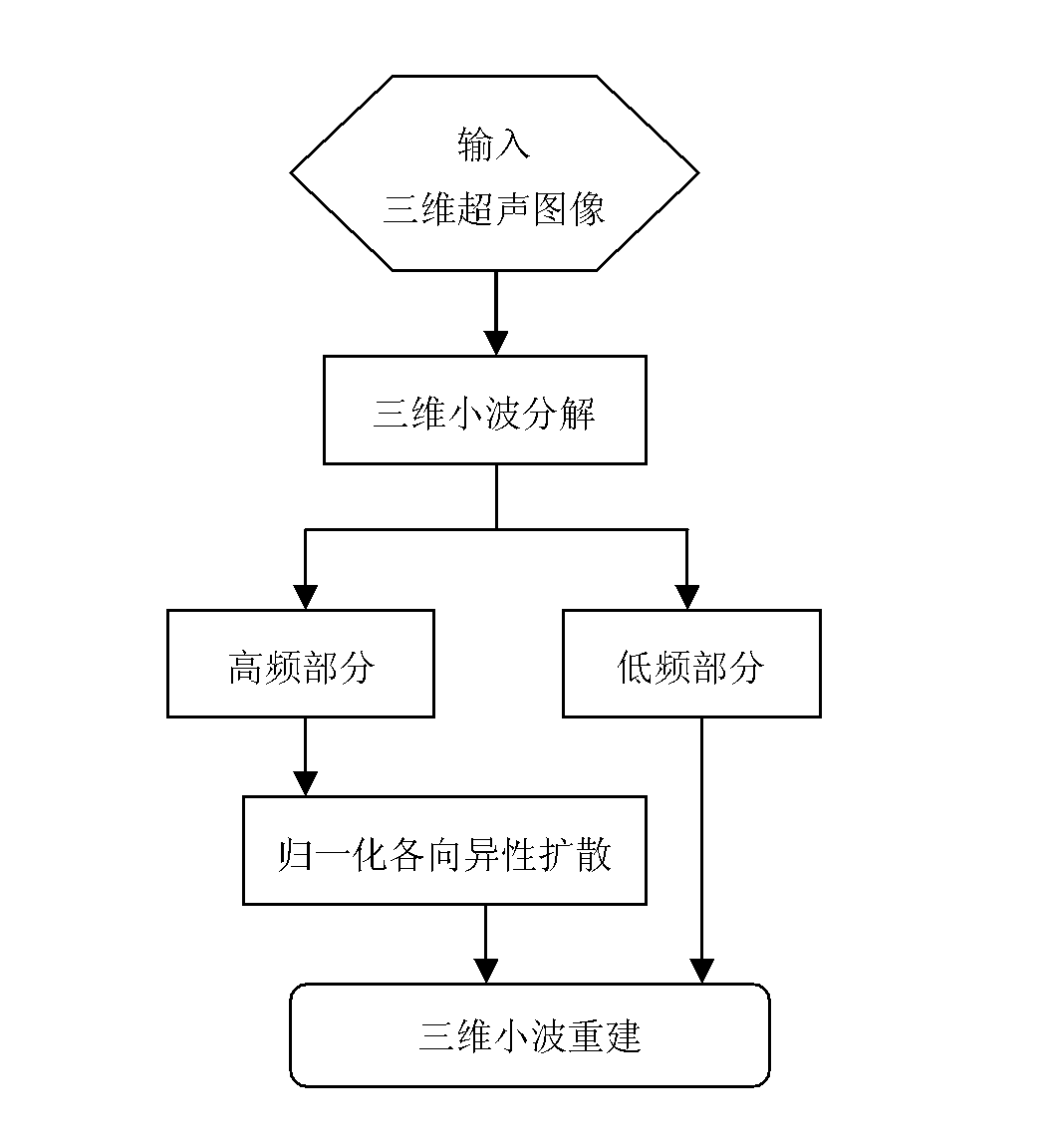

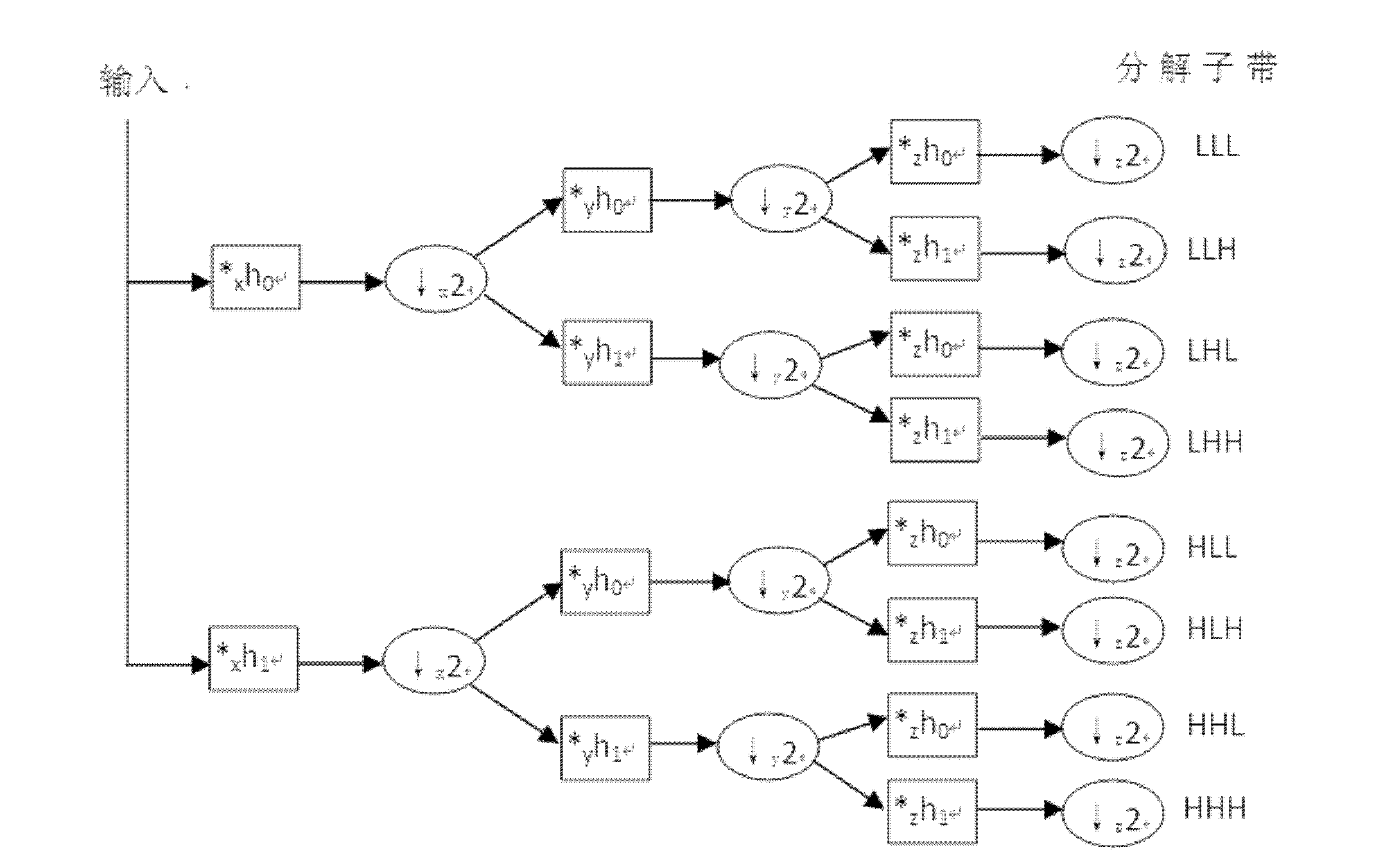

Method for segmenting three-dimensional ultrasonic image

InactiveCN102402788AEffective smoothingAccurate segmentationImage enhancementImage analysisComputed tomographyResonance

The invention discloses a method for segmenting a three-dimensional ultrasonic image, belonging to the technical field of the digital image processing. The method comprises the following steps: (1) preprocessing spots of the three-dimensional ultrasonic image by adopting a normalized anisotropic diffusion method of a three-dimensional wavelet according to the characteristics of the three-dimensional ultrasonic image to remove spot noise; (2) initializing the preprocessed three-dimensional ultrasonic image by adopting a Canny edge detection operator; and (3) segmenting the three-dimensional ultrasonic image three-dimensionally by using a B-Surface and GVF Snake based three-dimensional deformation model. The method disclosed by the invention can be used to rapidly and accurately segment the three-dimensional ultrasonic image and particularly has strong noise robustness. The method for automatically segmenting the three-dimensional ultrasonic image can be also used for segmenting other three-dimensional images such as CT (computed tomography) images, MRI (magnetic resonance images) and PET (position-emission tomography) images, thereby having high application value.

Owner:SOUTH CHINA UNIV OF TECH

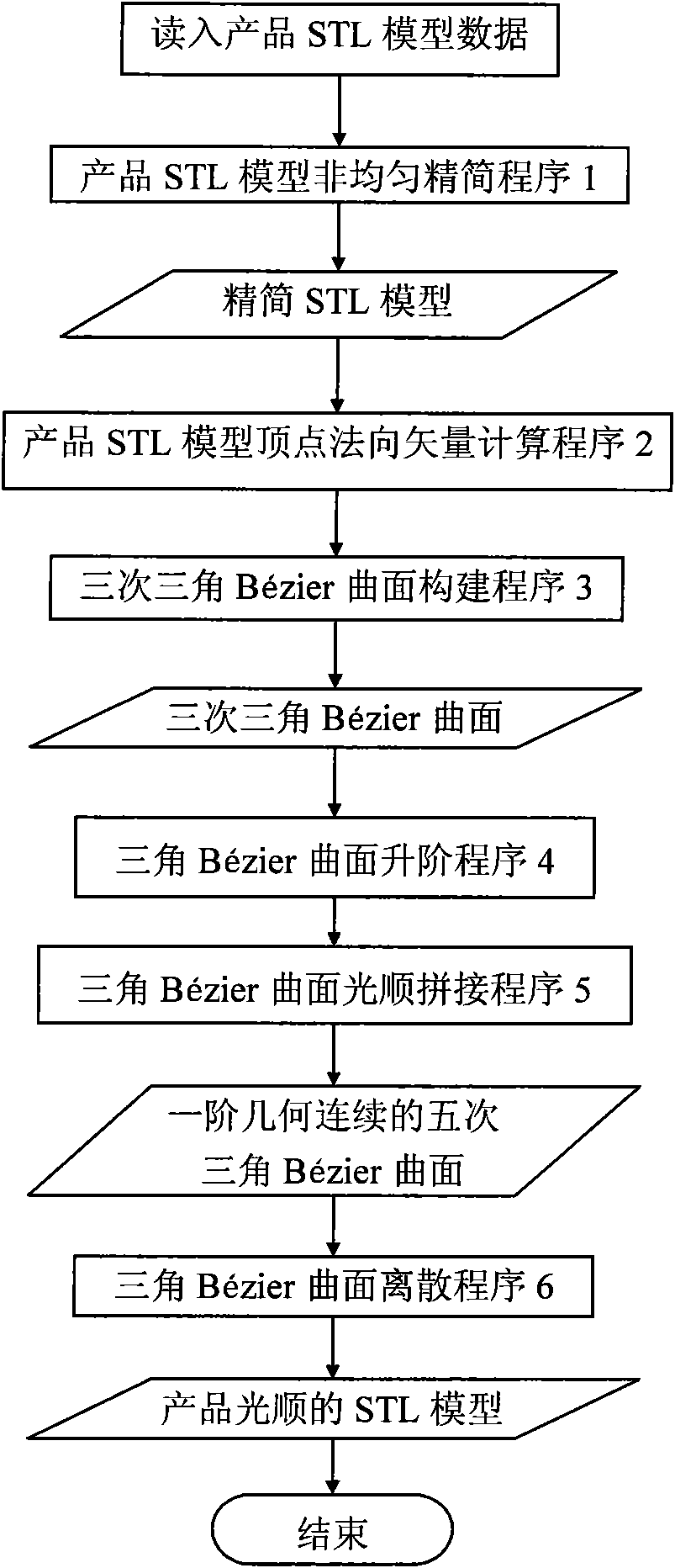

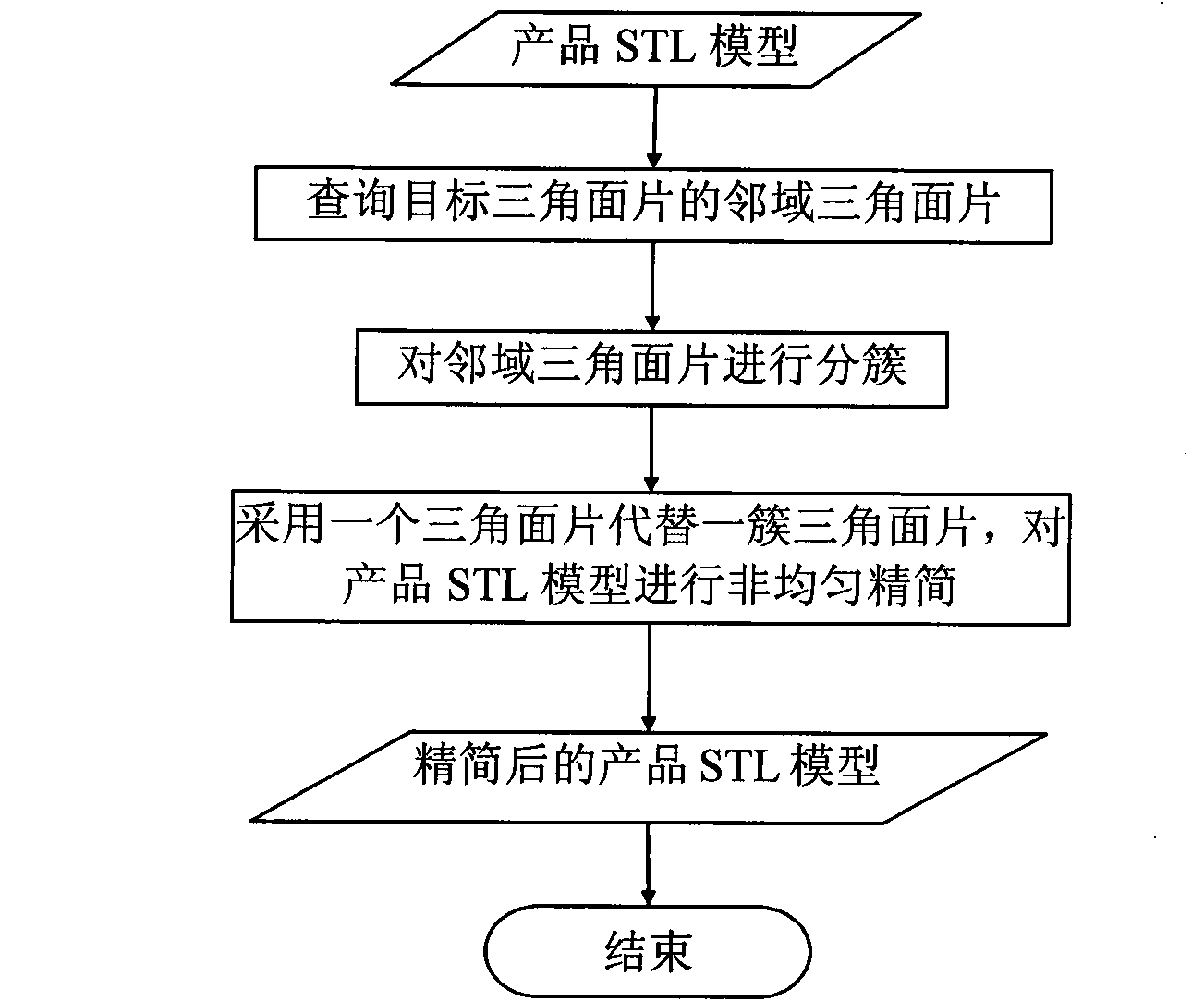

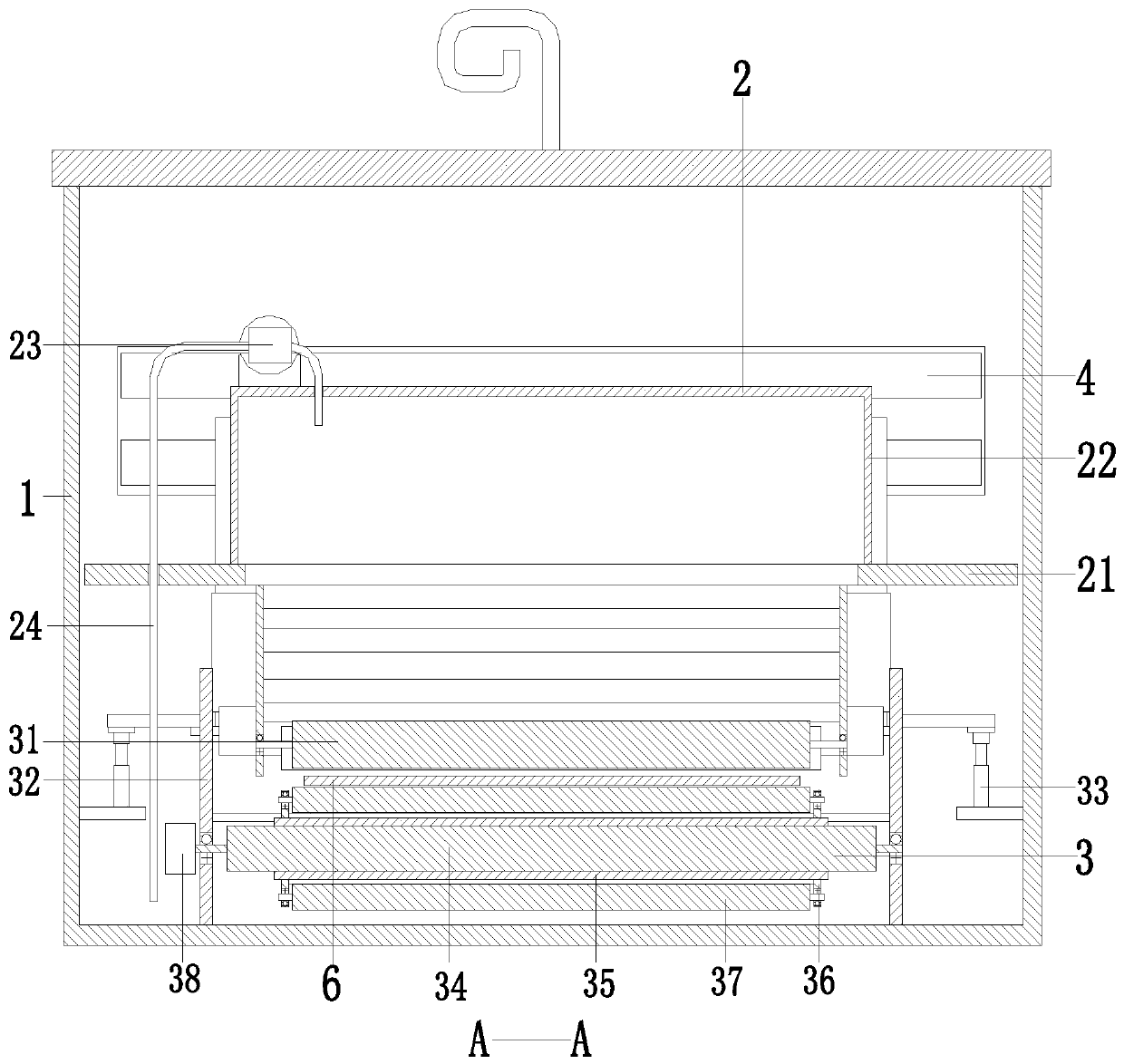

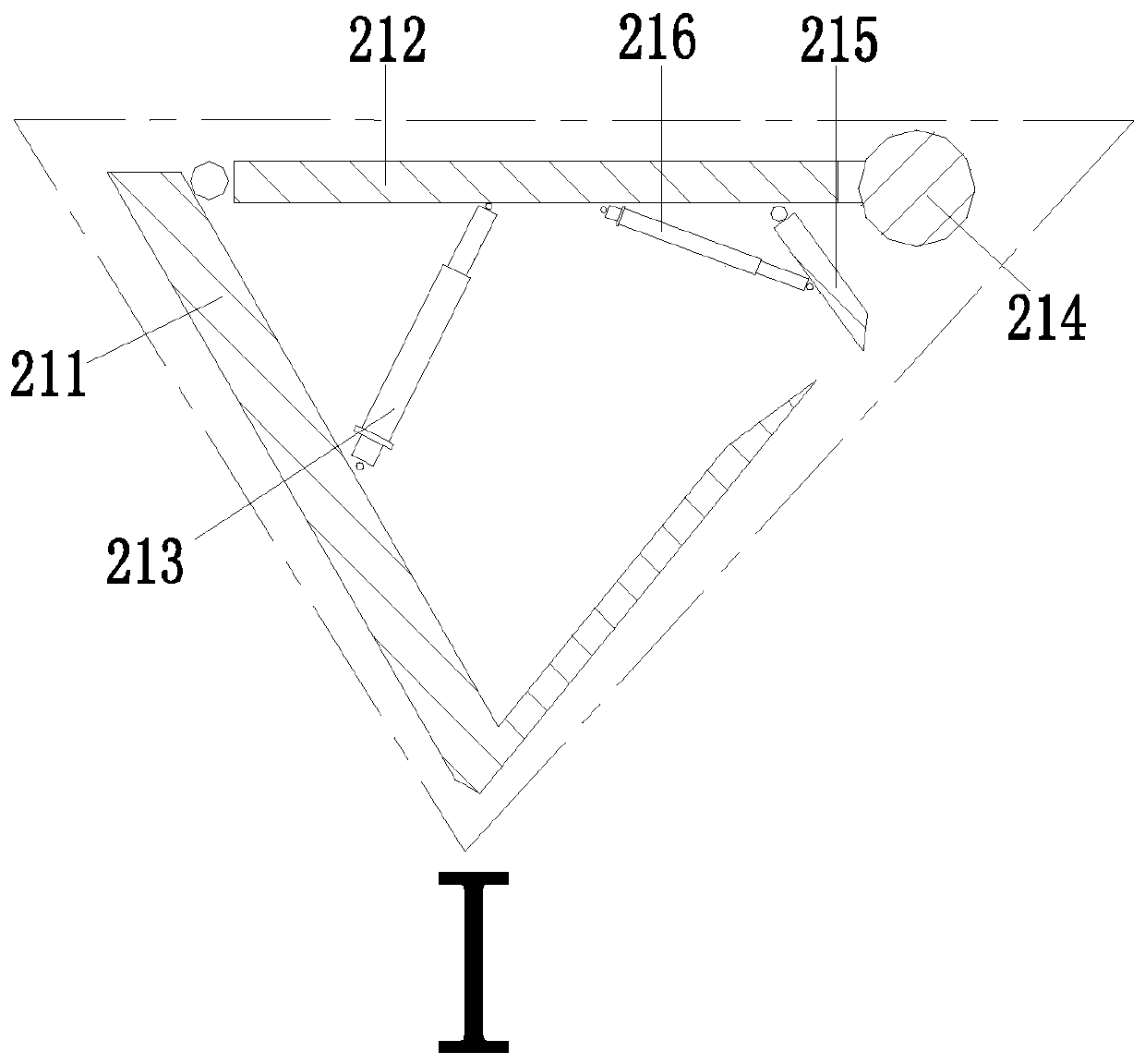

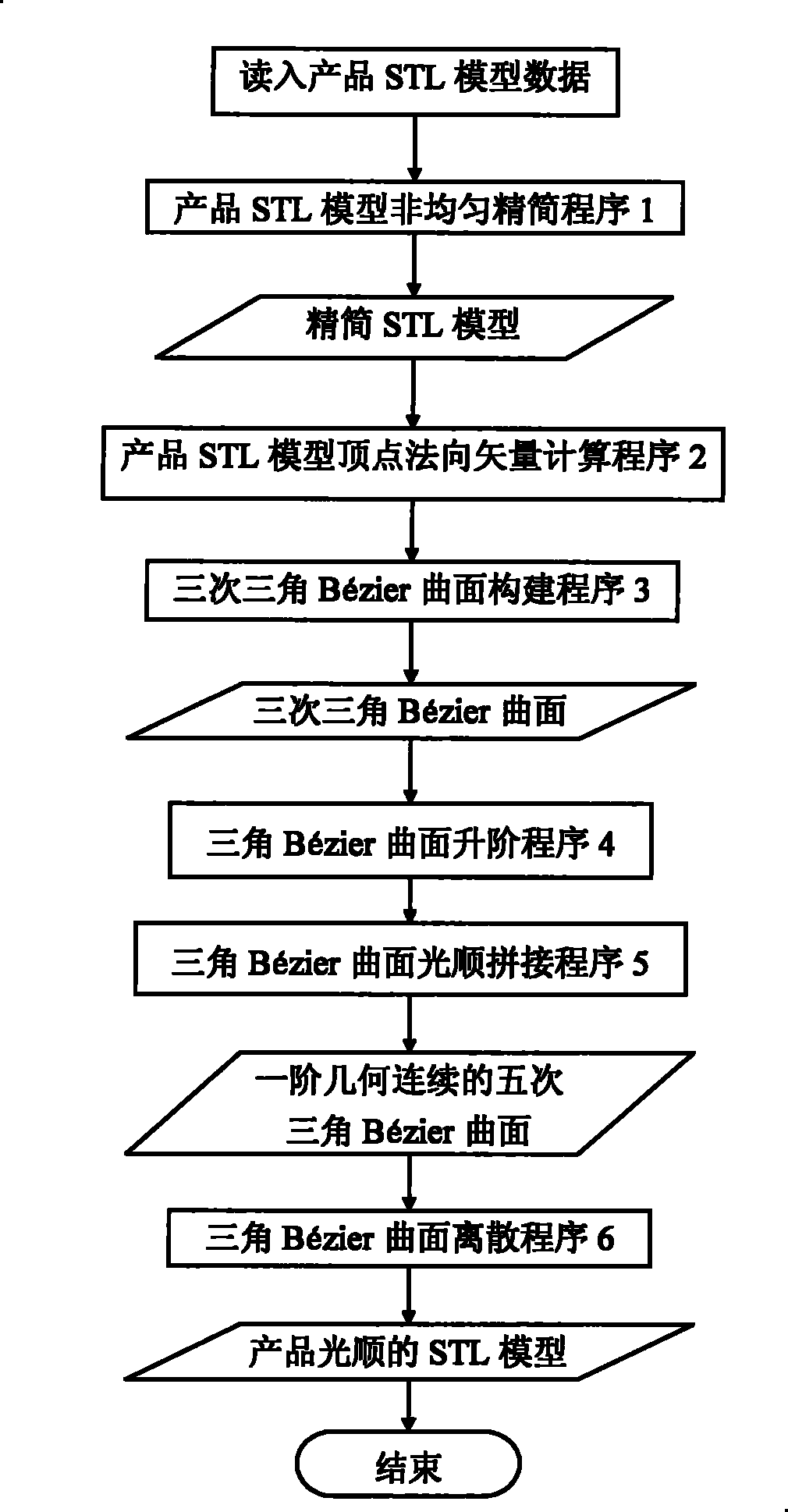

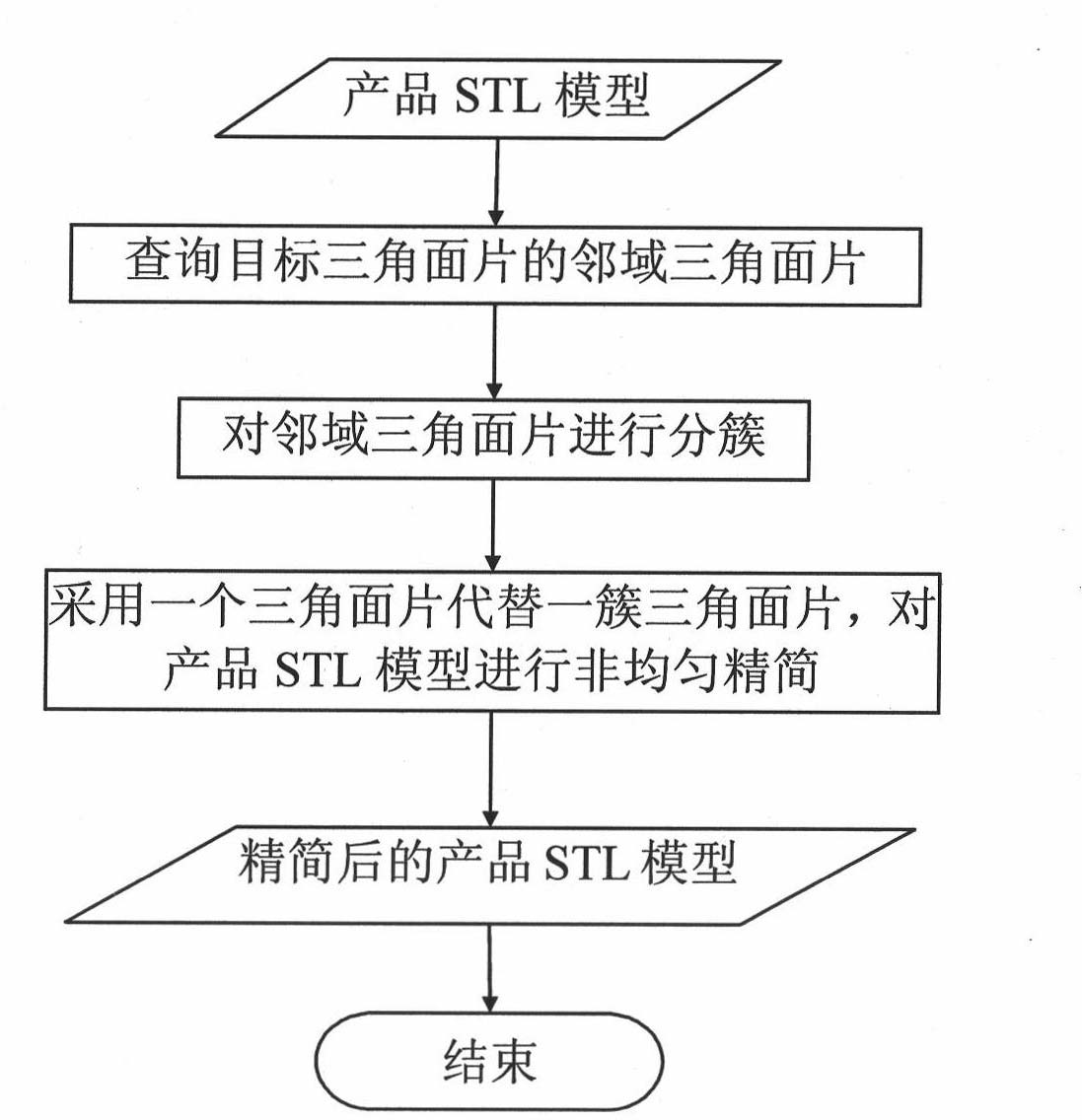

Triangle Bezier curved surface-based method for fairing STL model of products

Owner:SHANDONG UNIV OF TECH

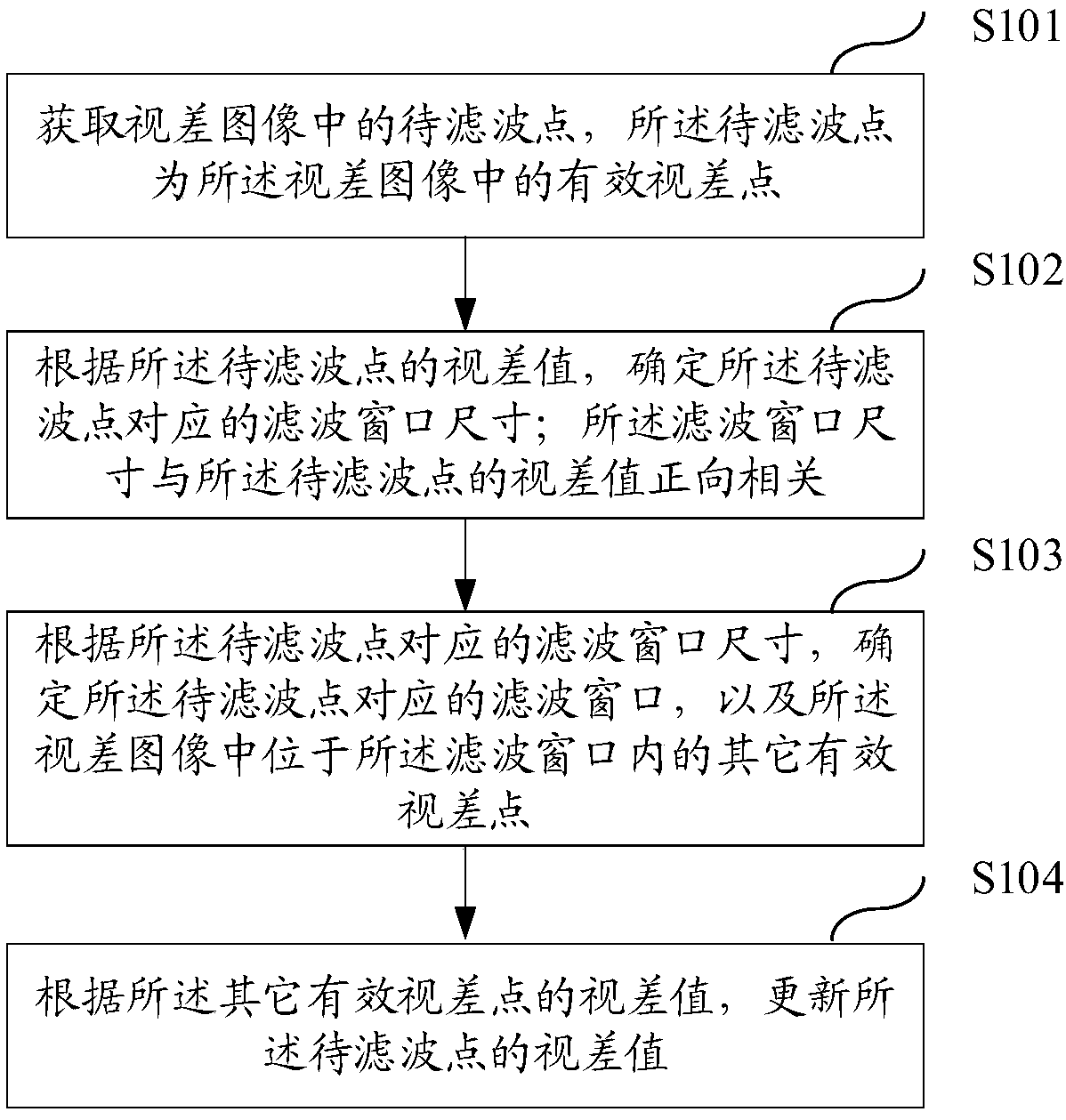

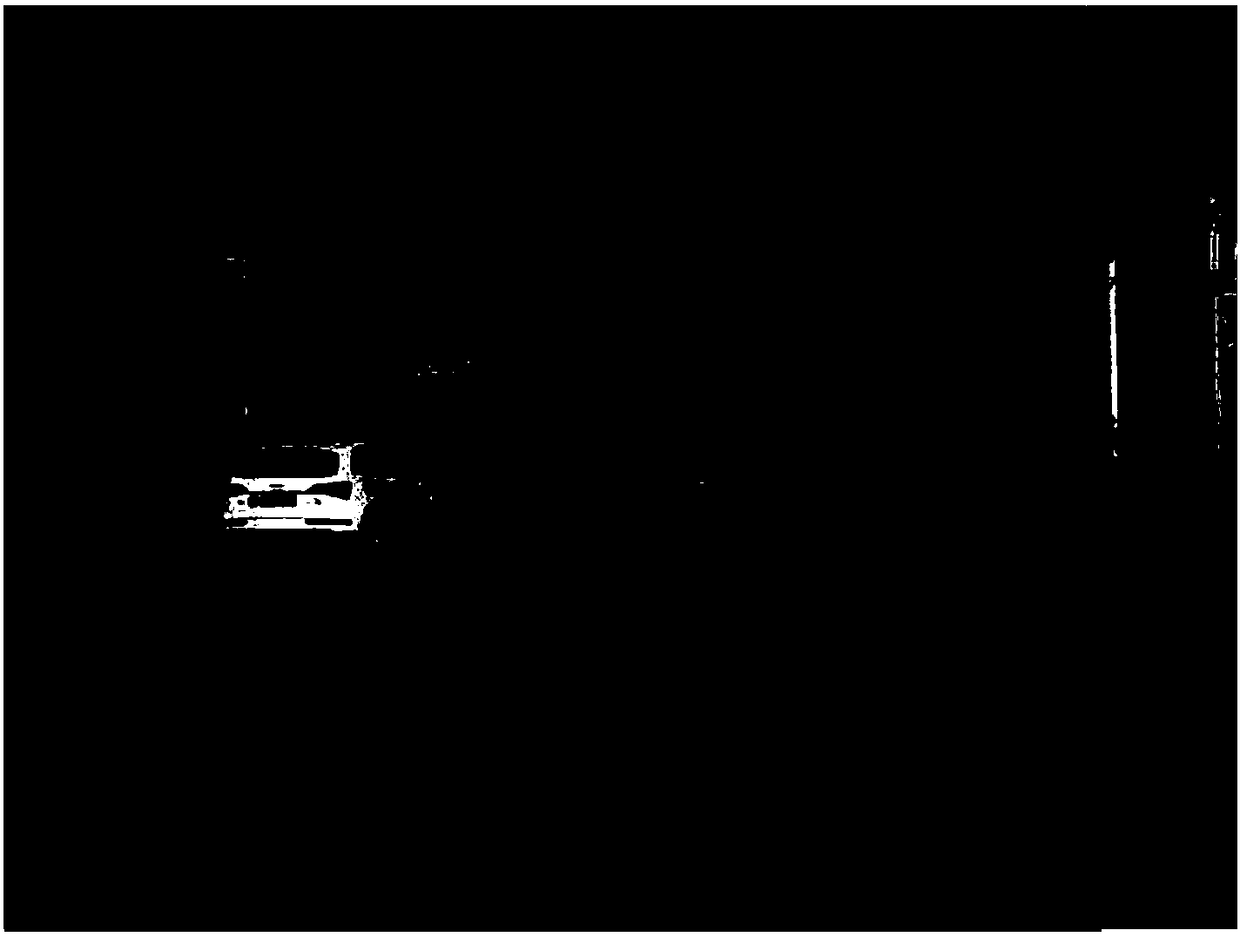

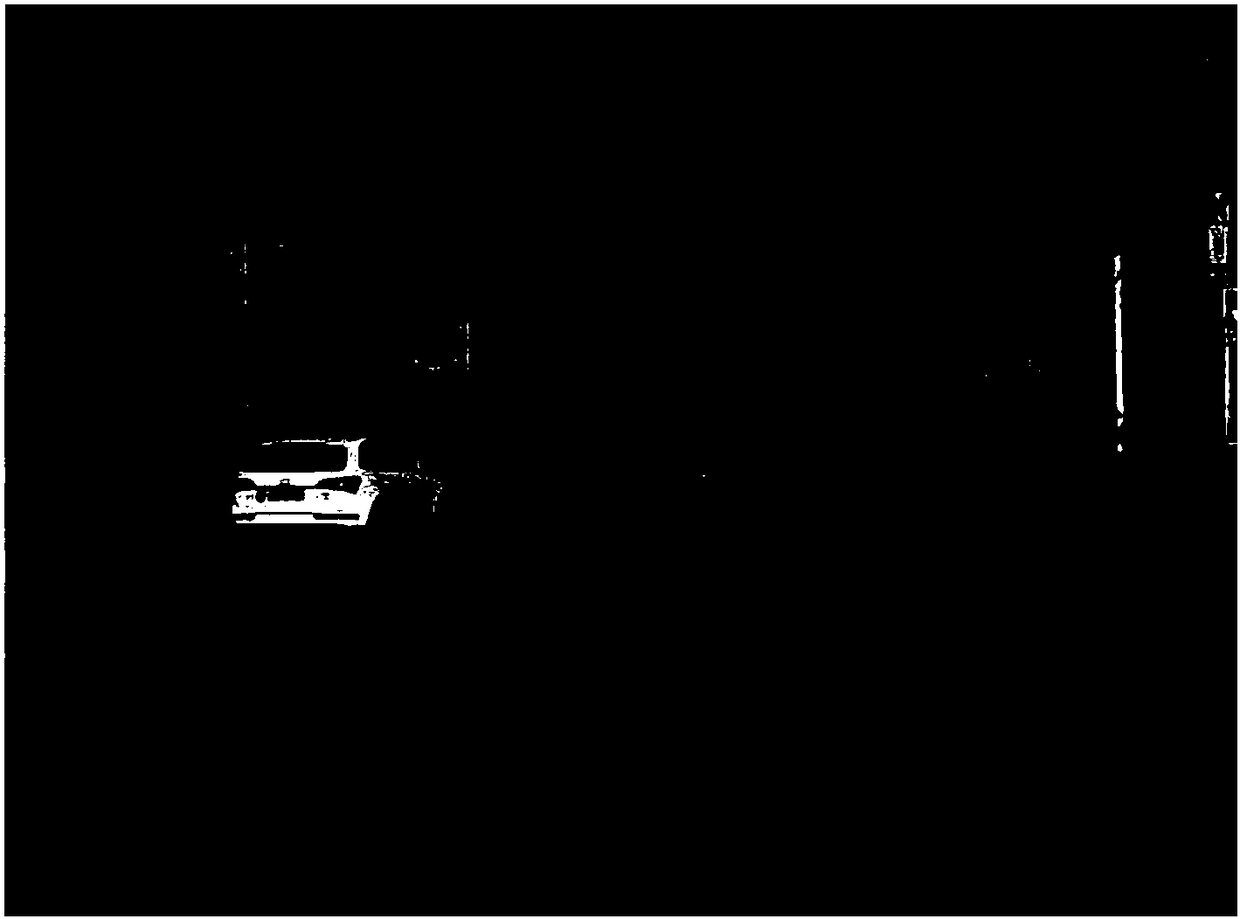

Parallax correction method, device and terminal

ActiveCN108182666AEffective smoothingImprove denoising effectImage enhancementParallaxComputer graphics (images)

The embodiment of the invention discloses a parallax correction method, device and terminal. The method comprises: acquiring a point to be filtered in a parallax image, determining a filtering windowsize according to the parallax value of the point to be filtered, wherein the size is positively correlated with the parallax value; determining the filtering window of the point to be filtered and updating the parallax value of the point to be filtered according to the parallax value of the valid parallax point in the filtering window. Since the filtering window size can be set to be positively correlated with the parallax value of the point to be filtered, in view that the parallax value is inversely proportional to the distance and the different filtering effects are required according to different distances, and the closer the distance is, the larger the filtering window of the point to be filtered is, and the farther the distance is, the smaller the filtering window of the point to befiltered is. When the parallax value of the point to be filtered is corrected, the filtering effect of the parallax points at different distances can be well balanced according to the parallax valuesof other valid parallax points in the filtering window, thereby effectively smoothing the parallax image and reducing the late detection and recognition difficulty.

Owner:HISENSE

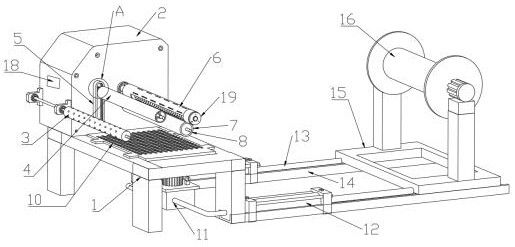

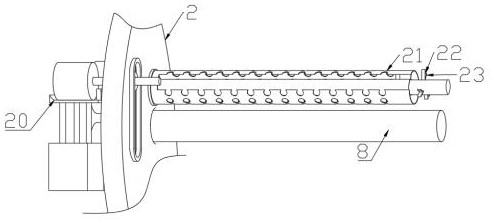

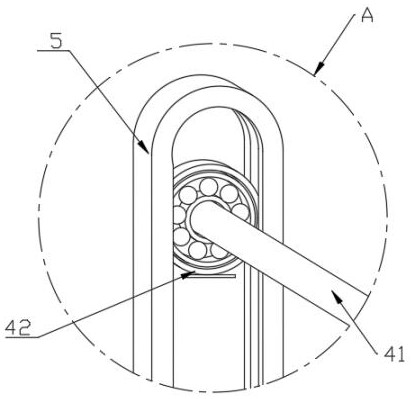

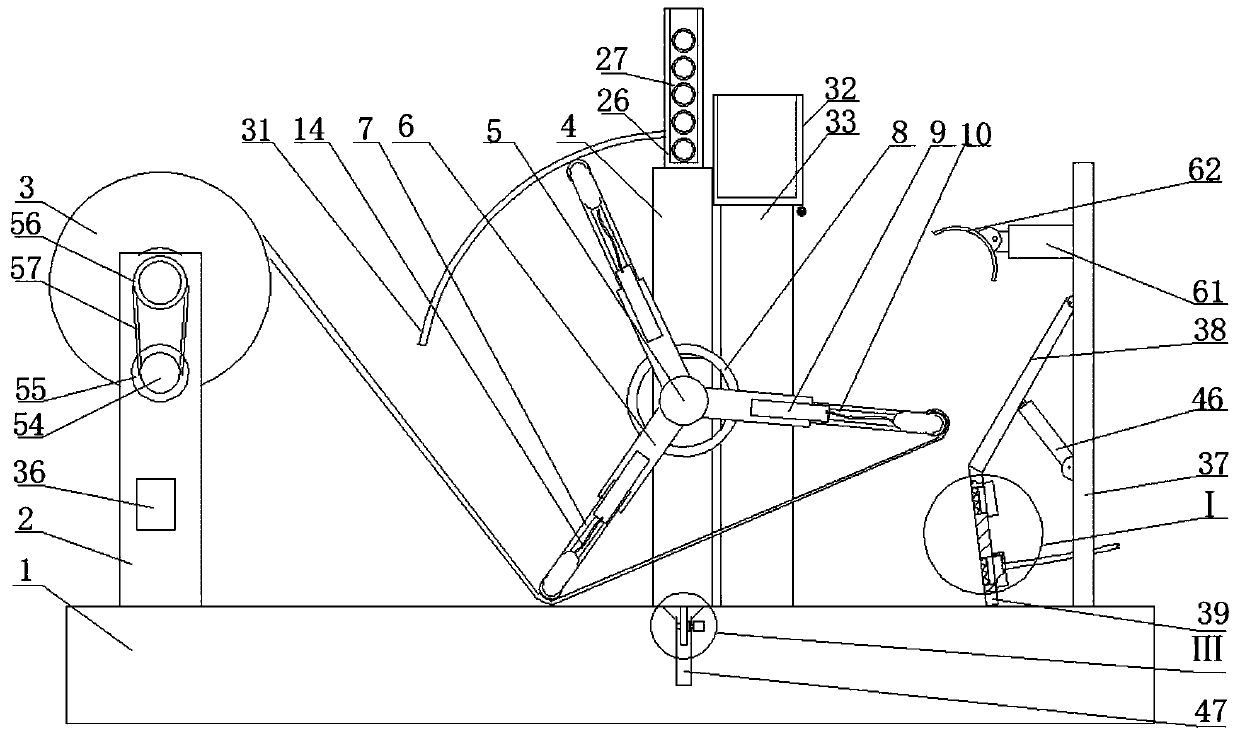

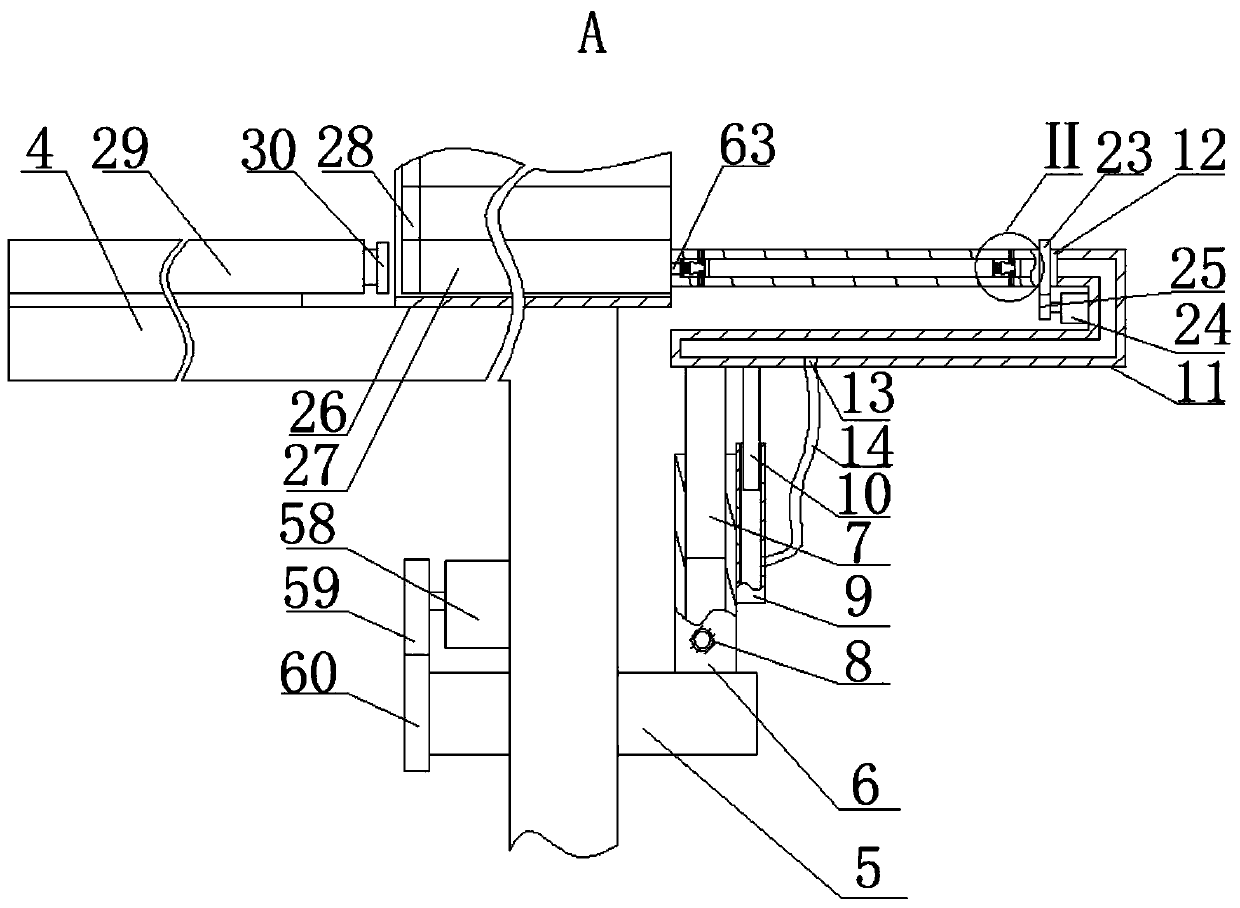

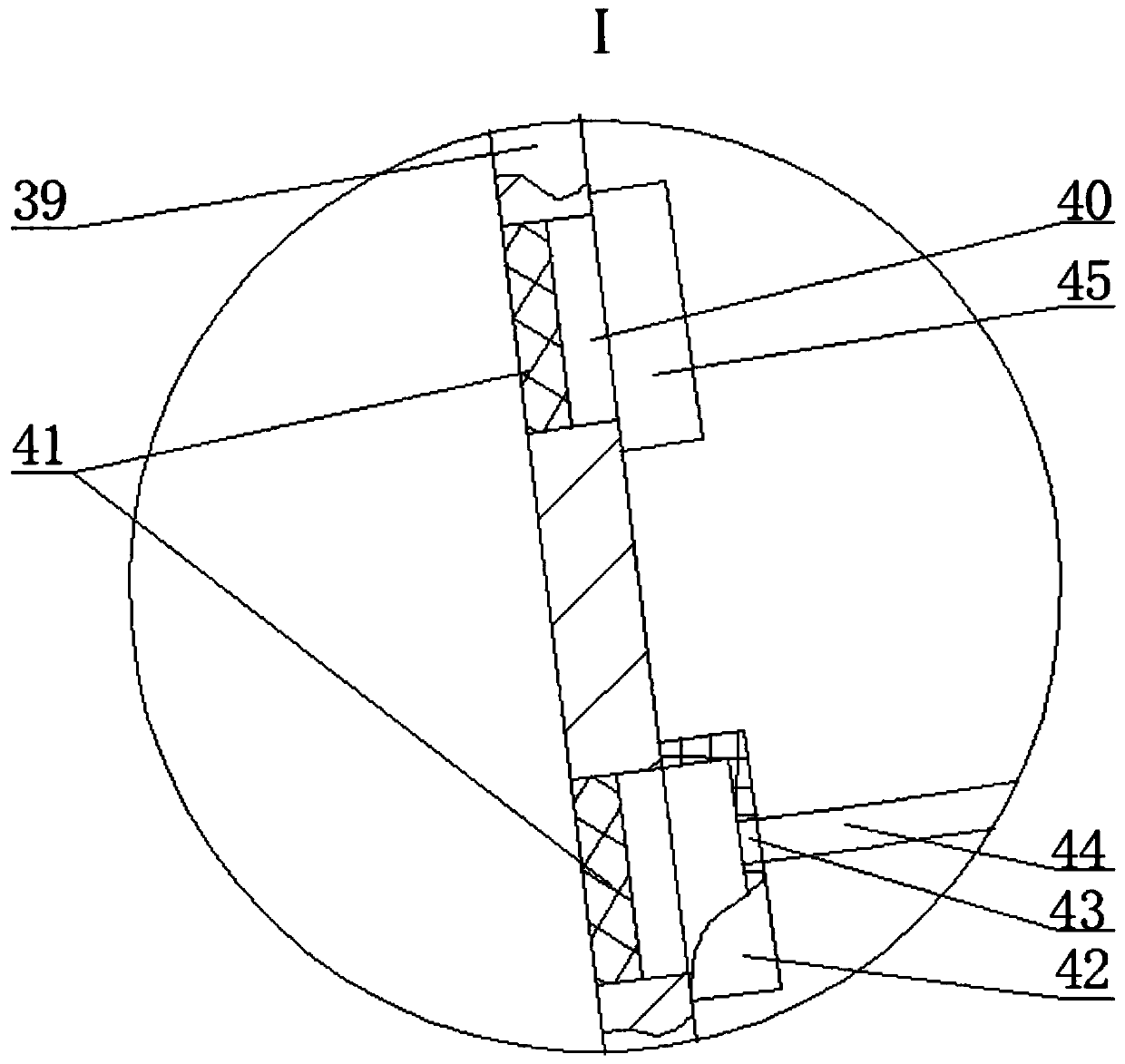

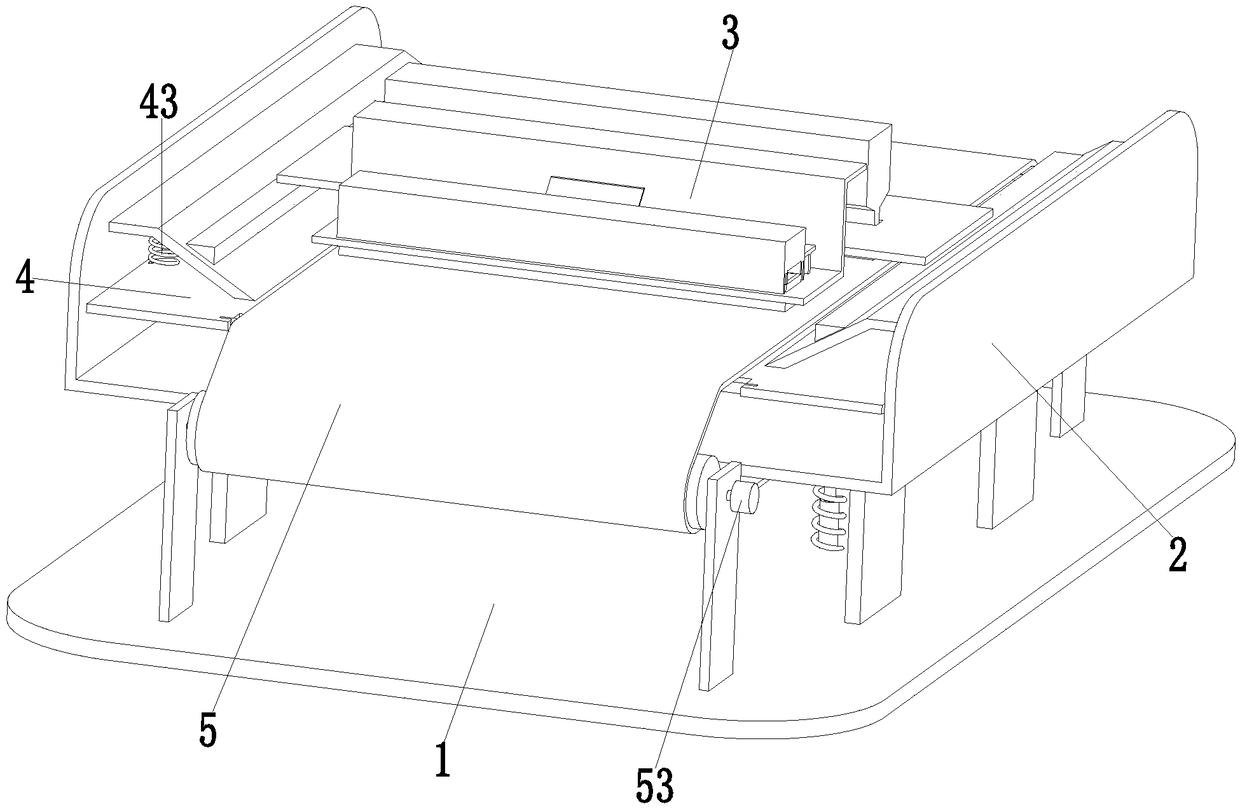

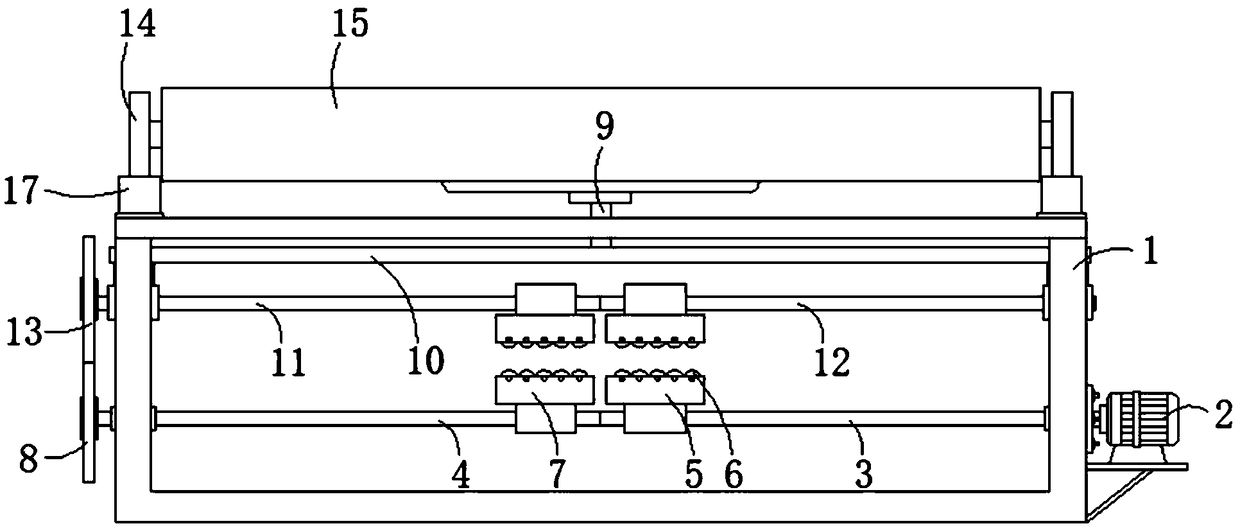

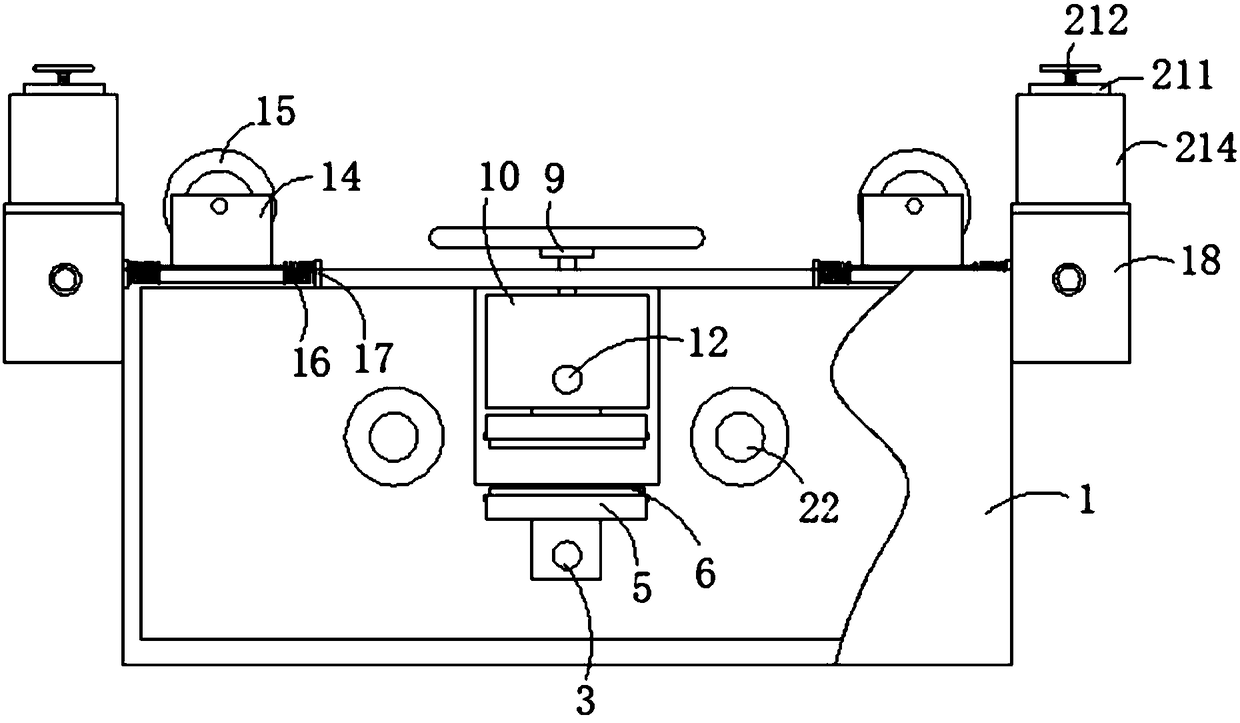

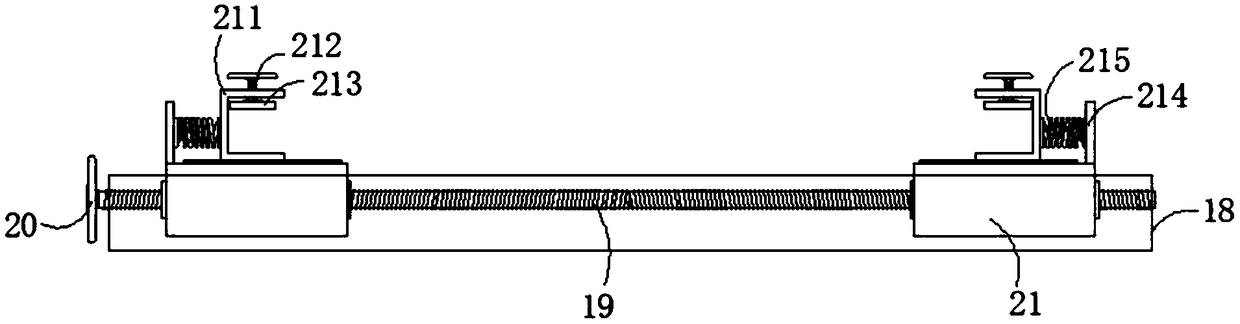

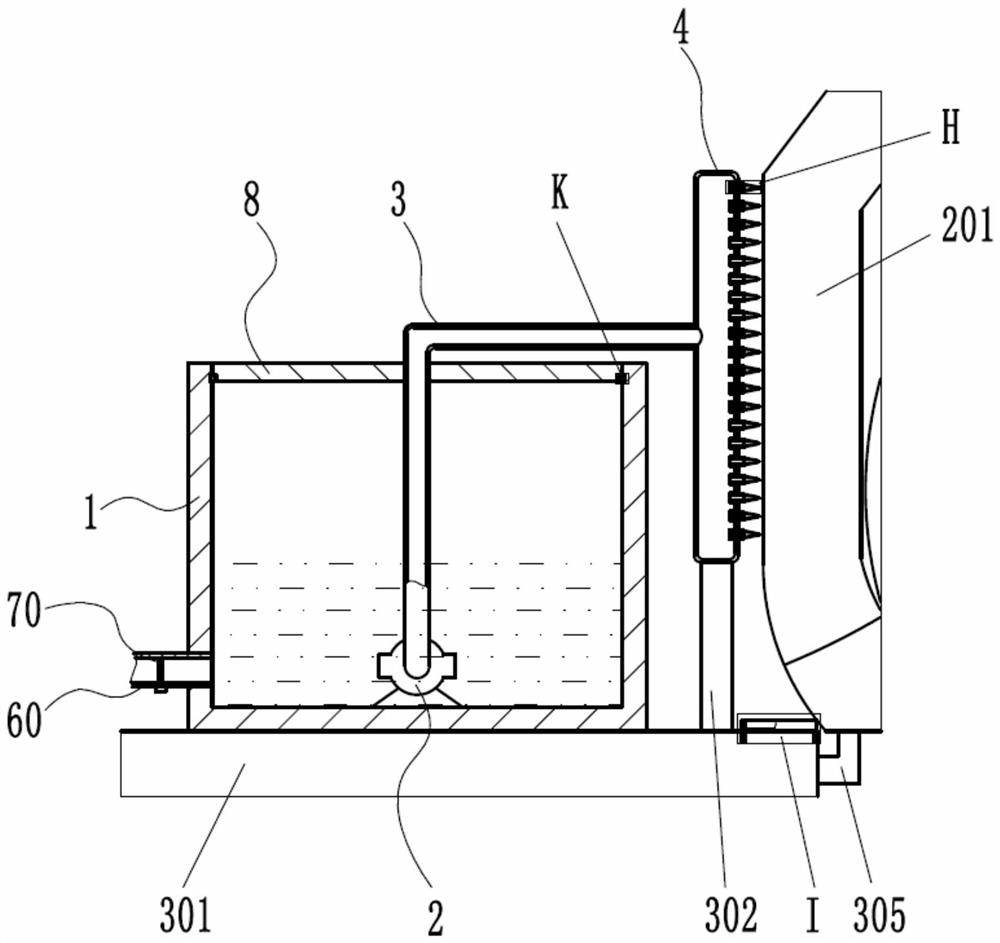

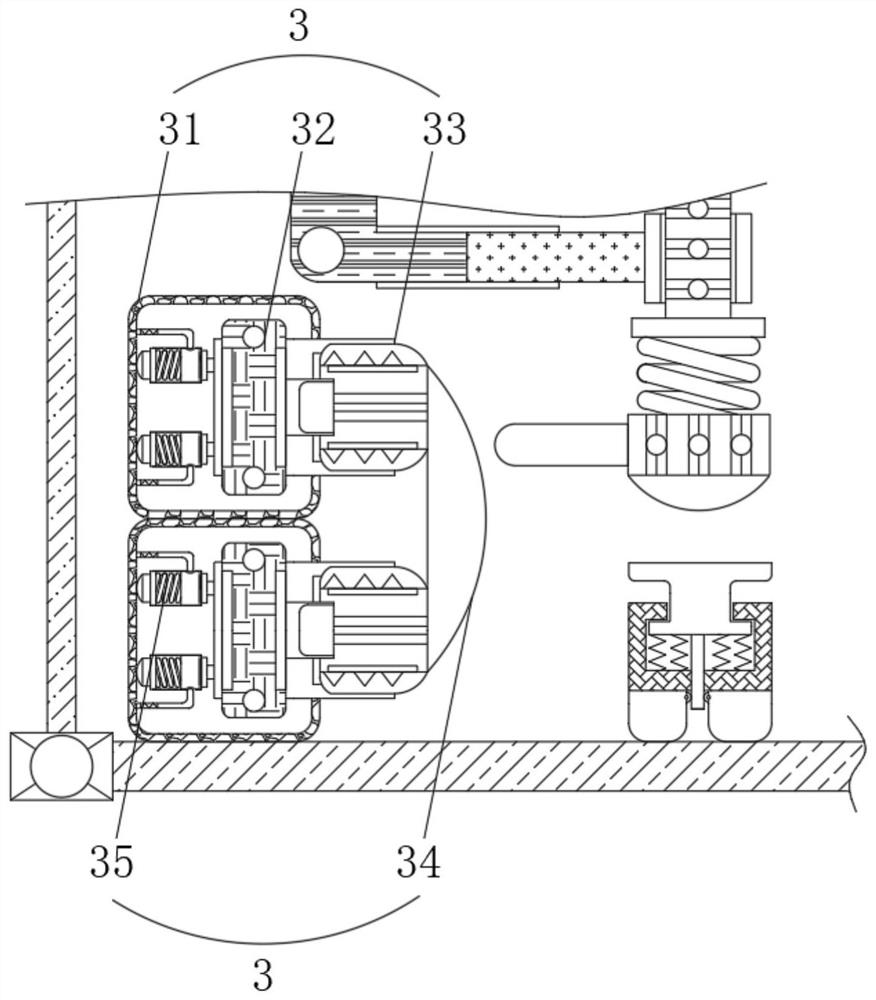

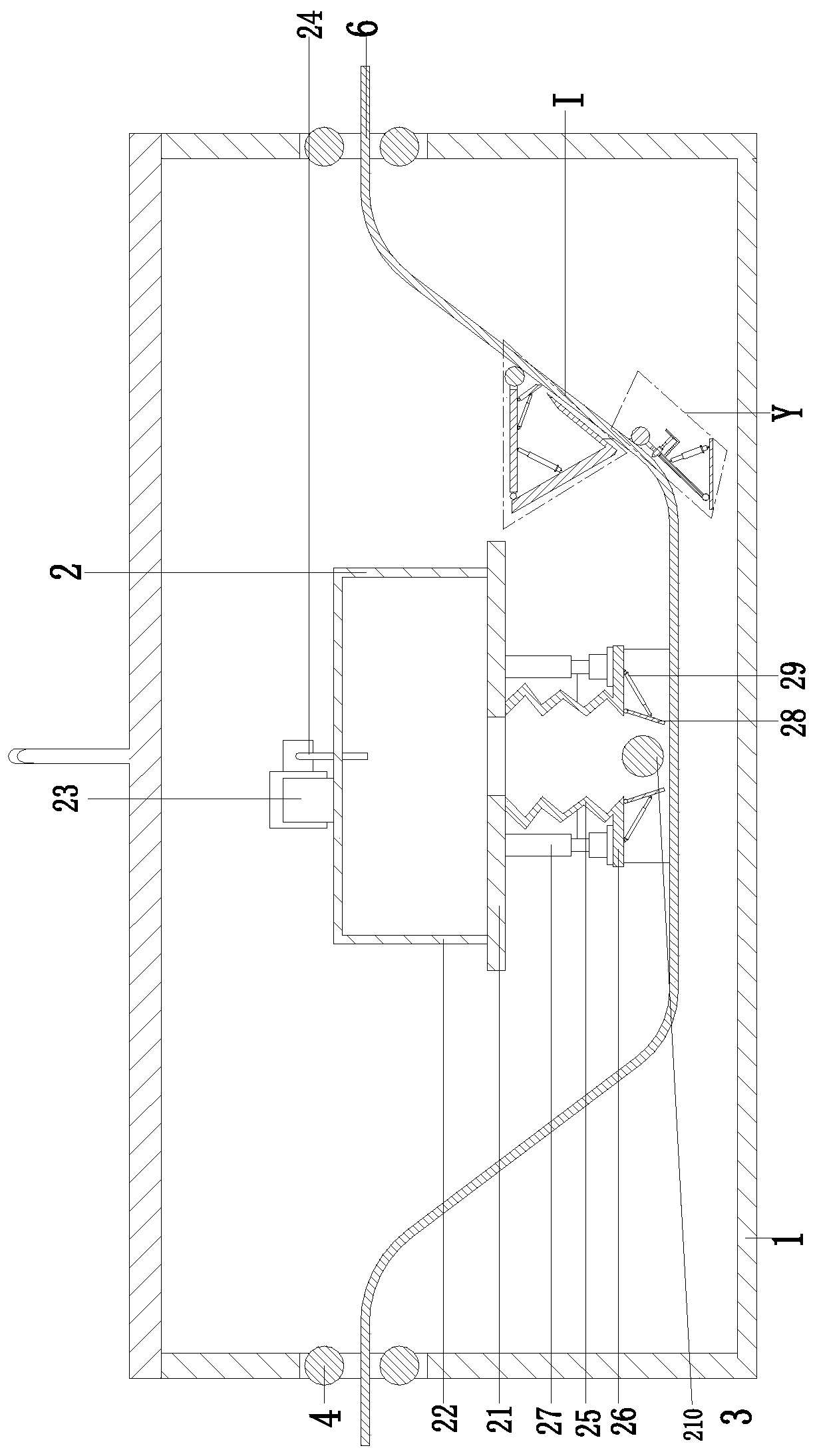

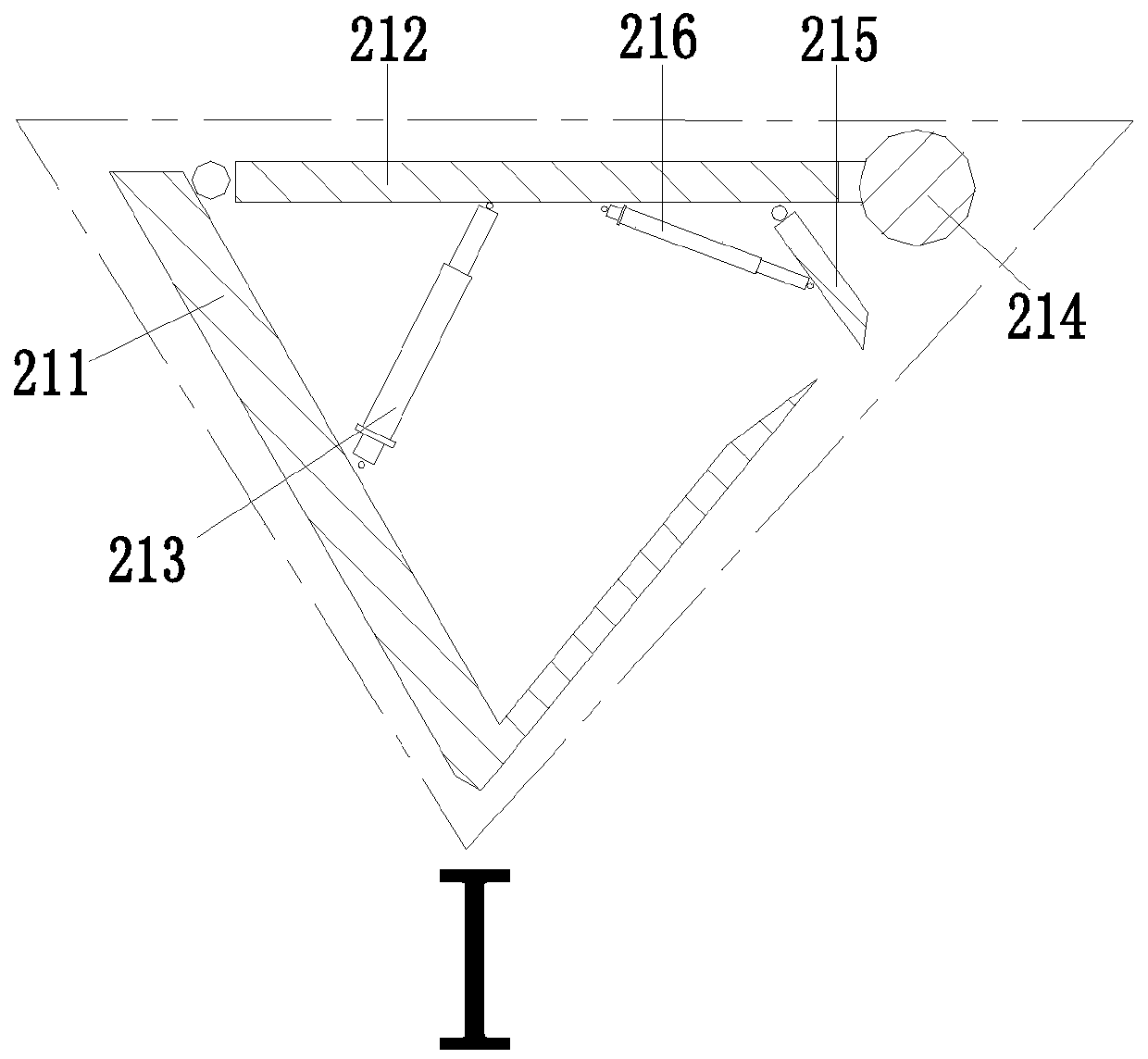

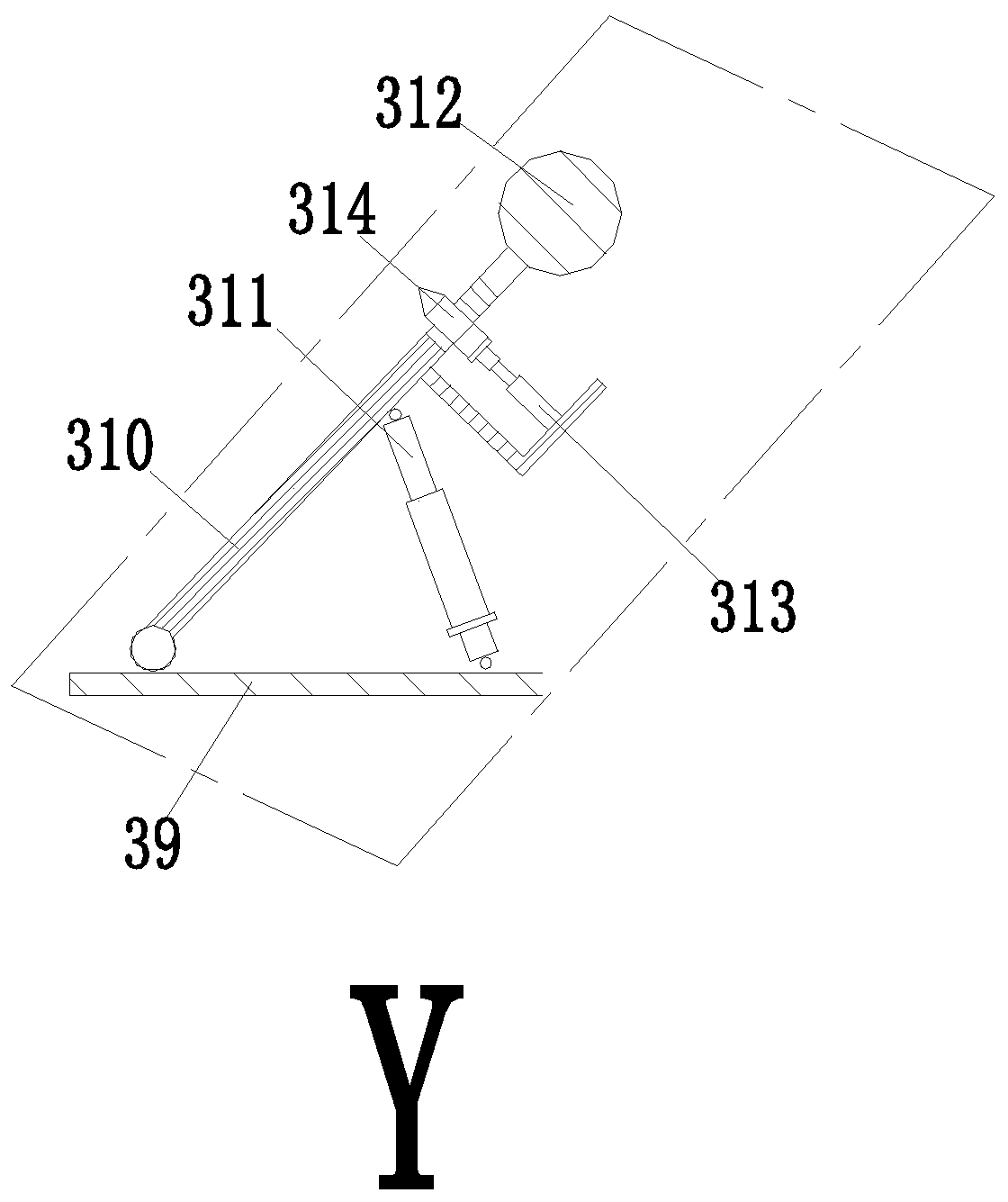

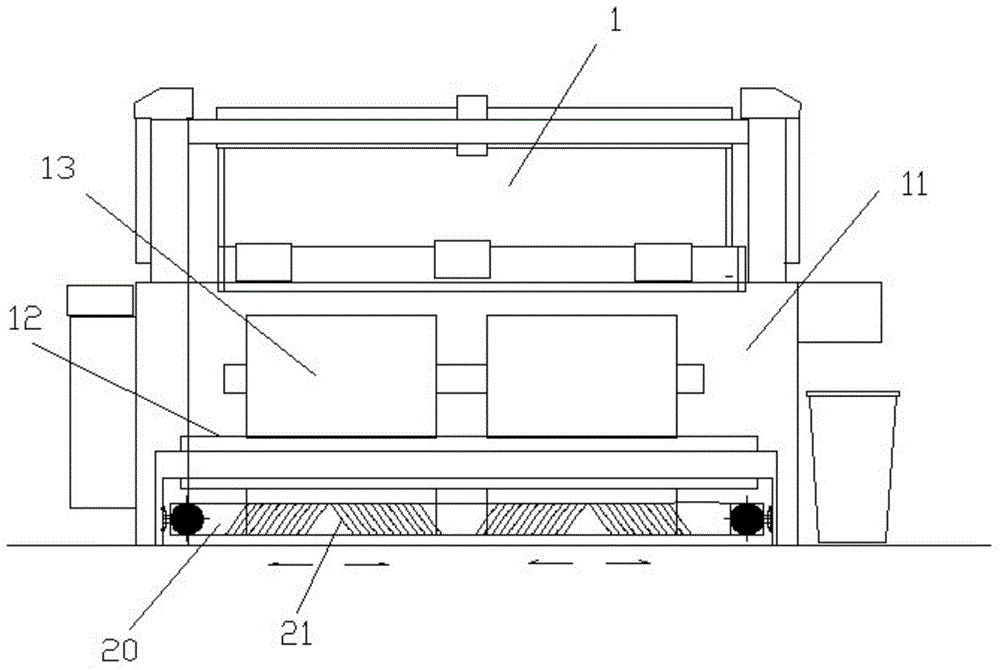

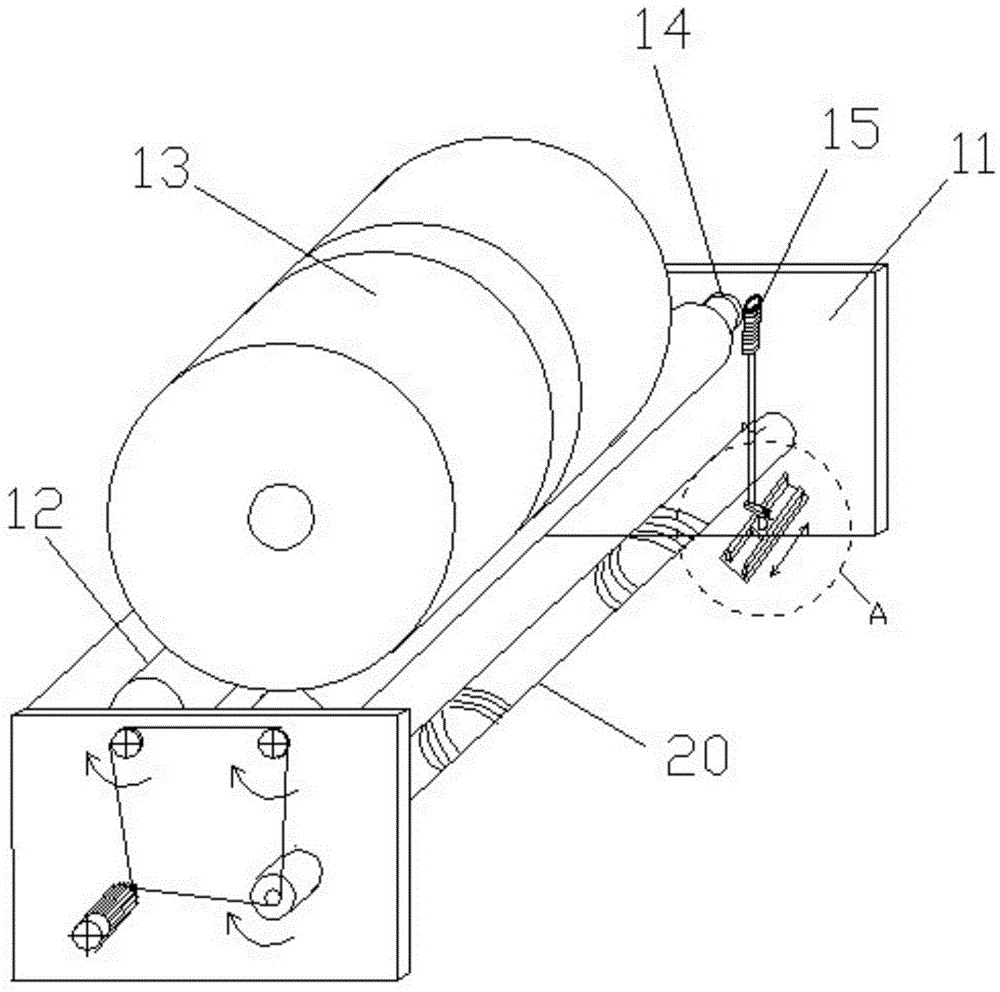

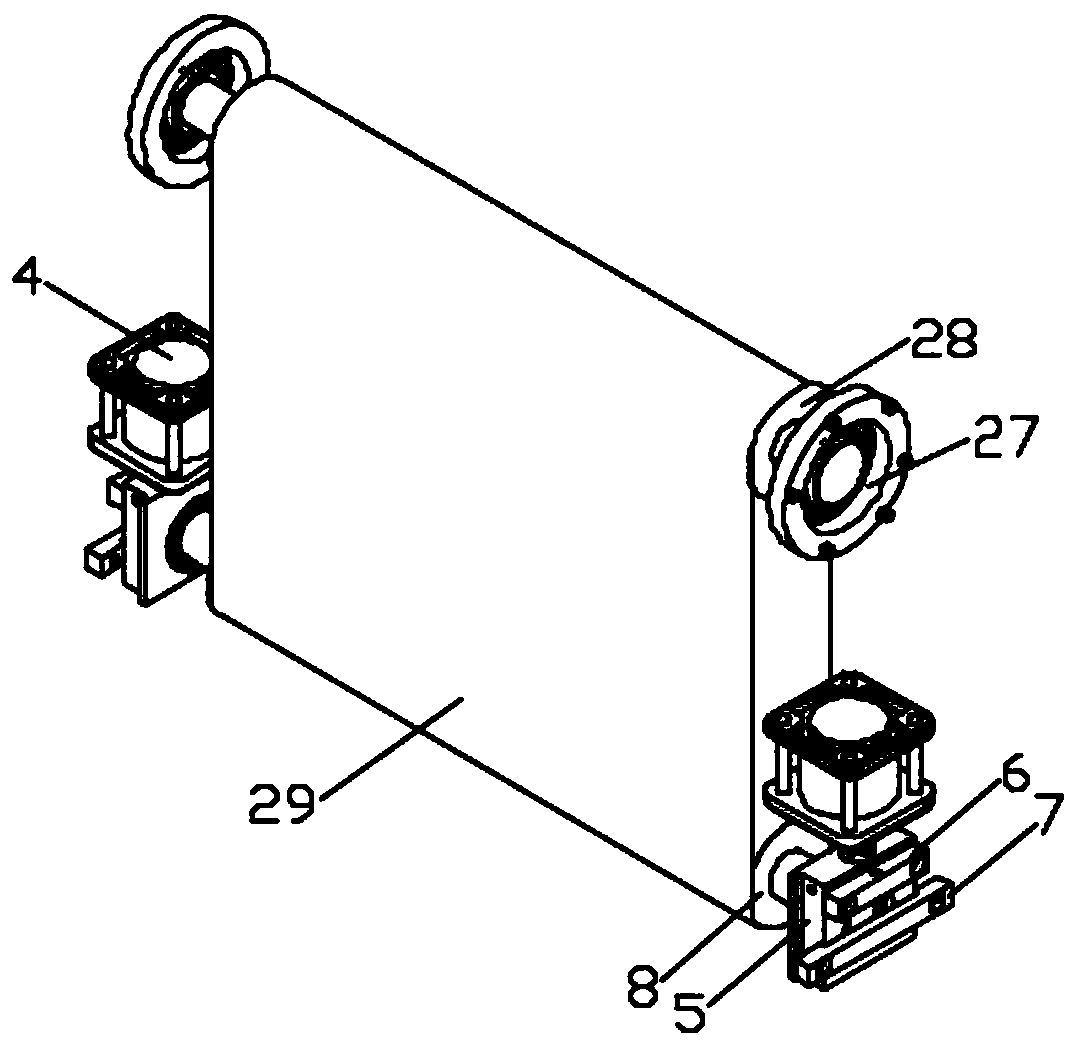

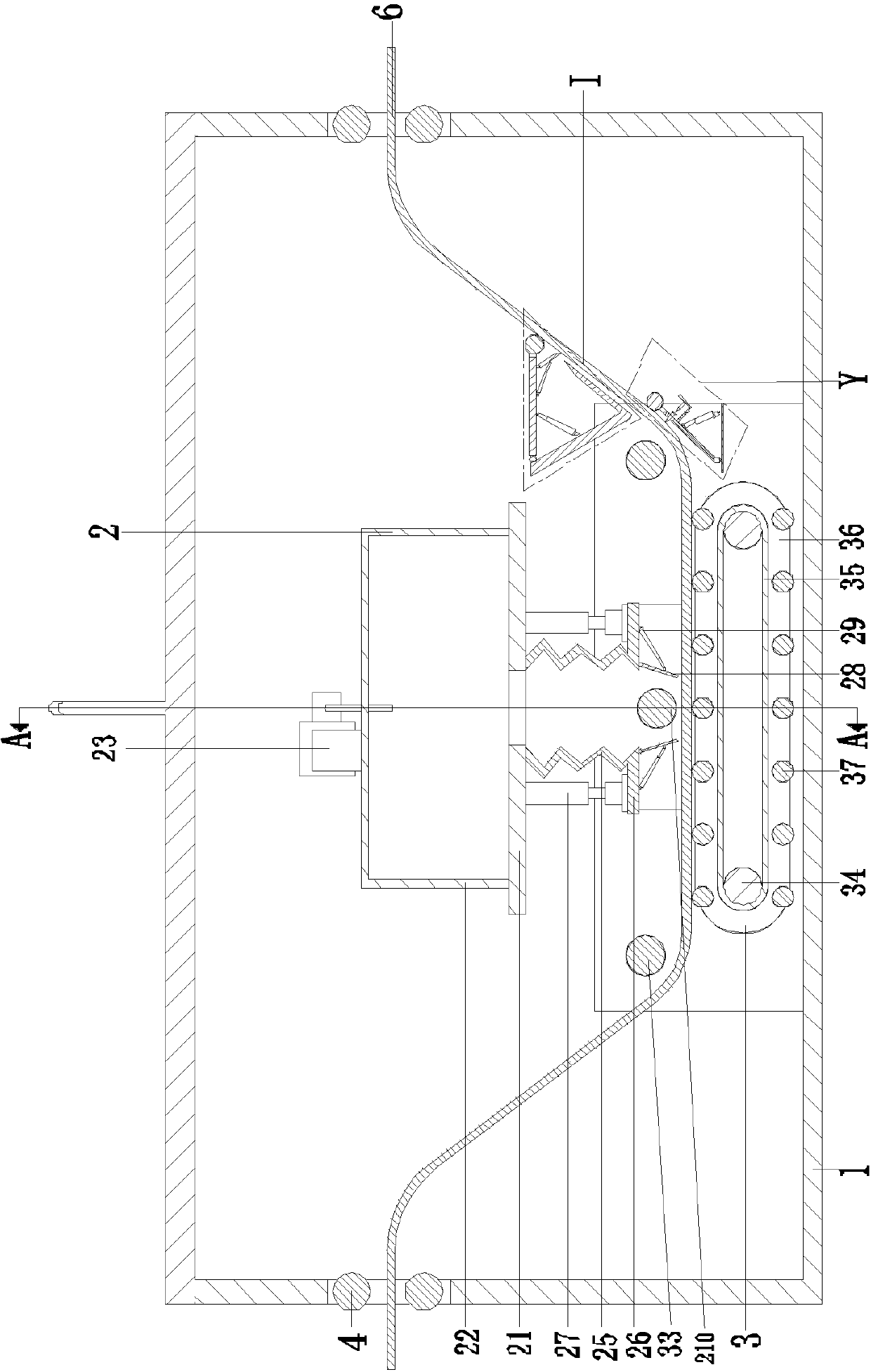

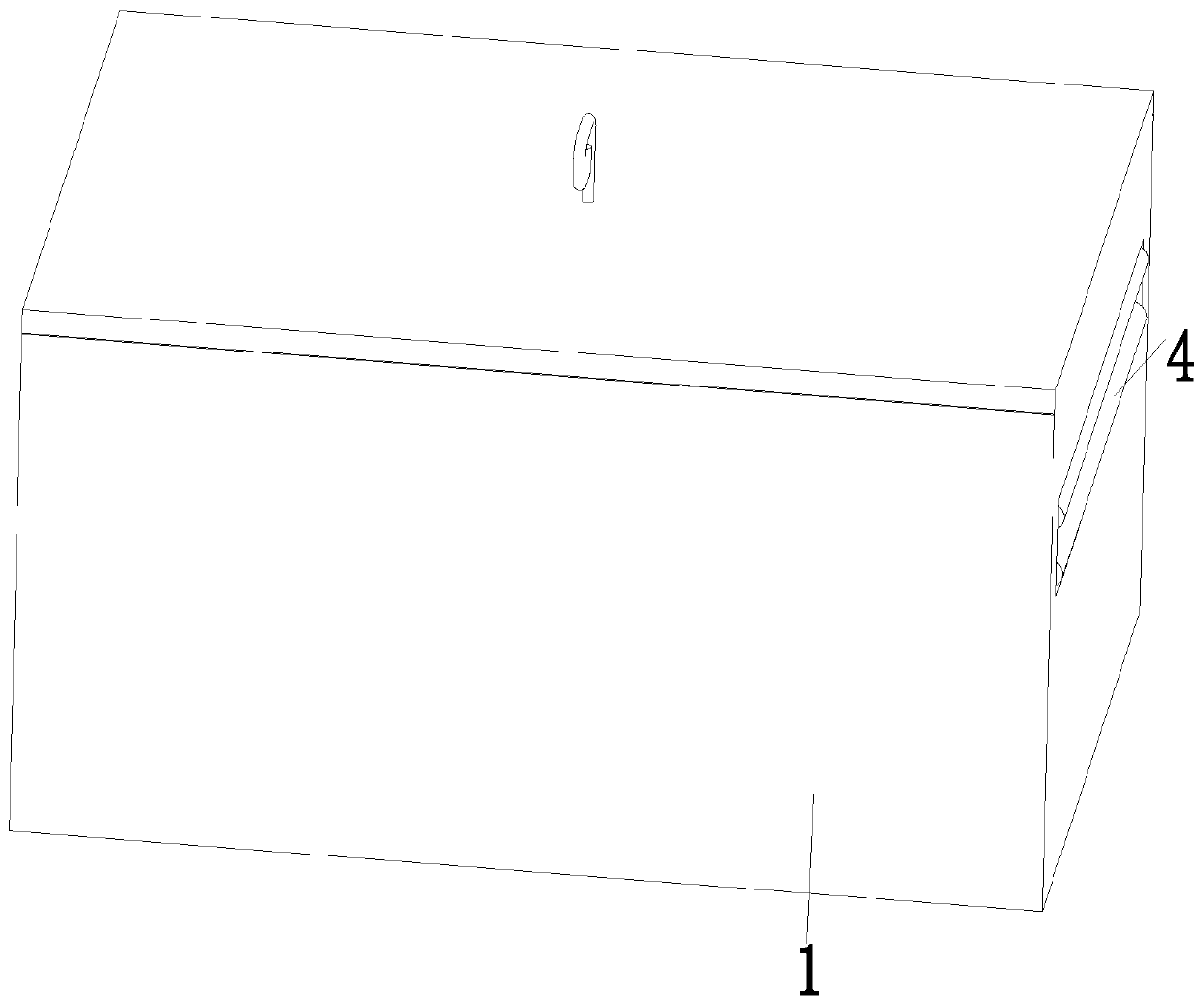

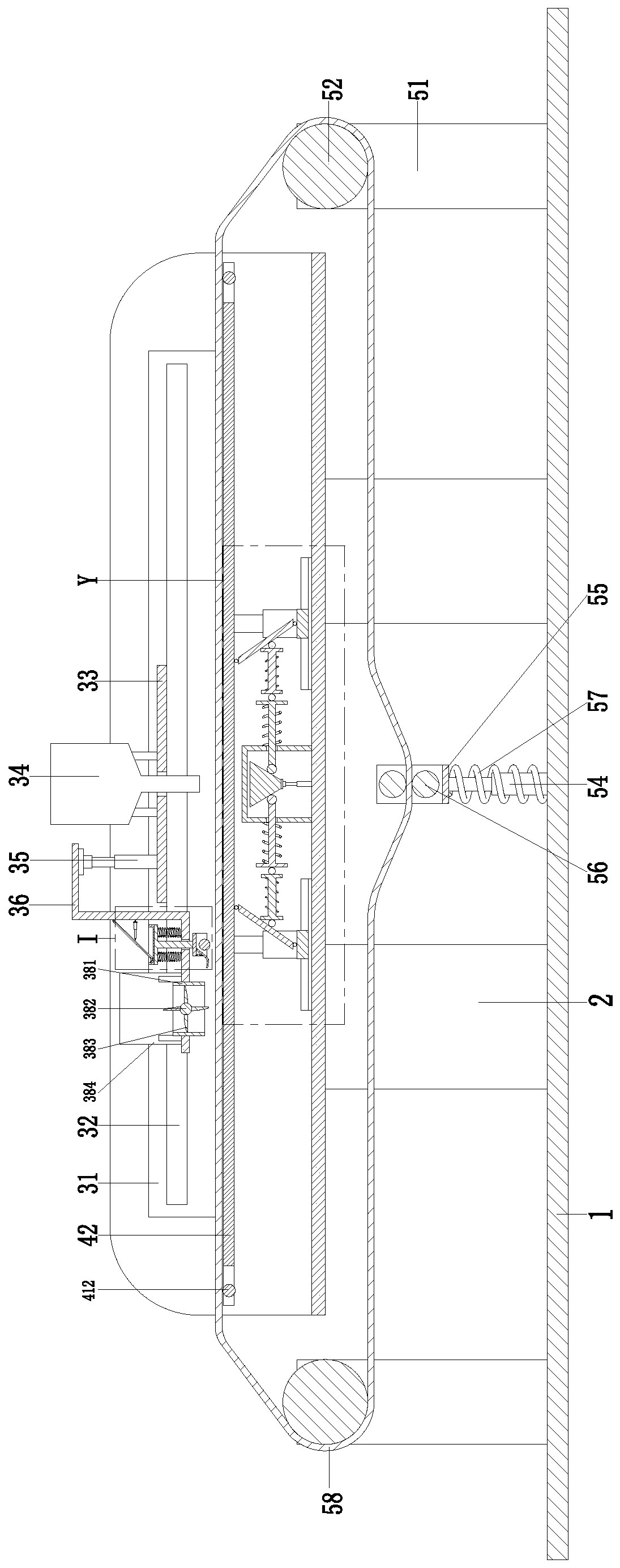

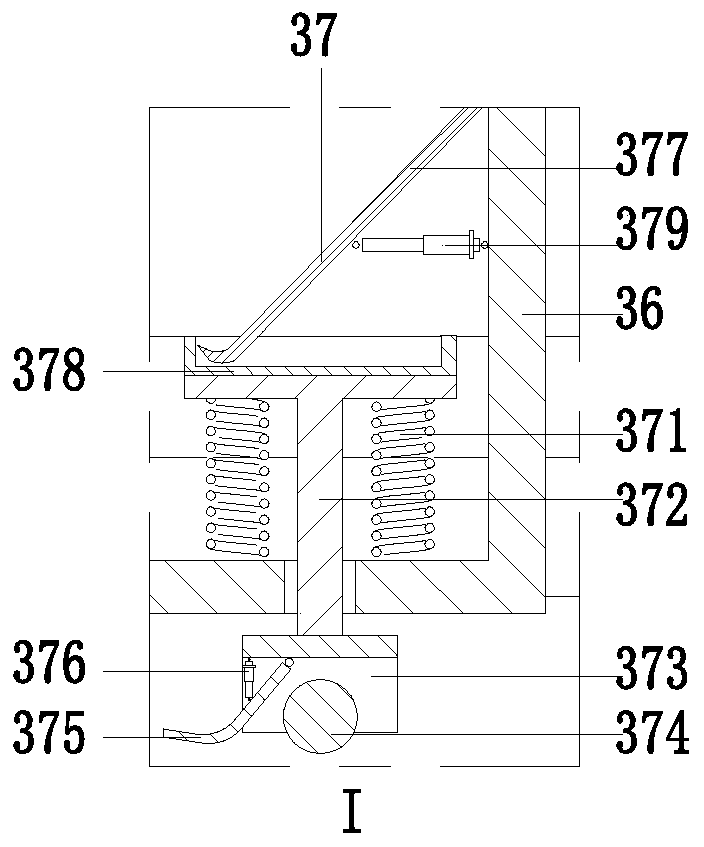

Intelligent fabric winding equipment with fabric flattening function

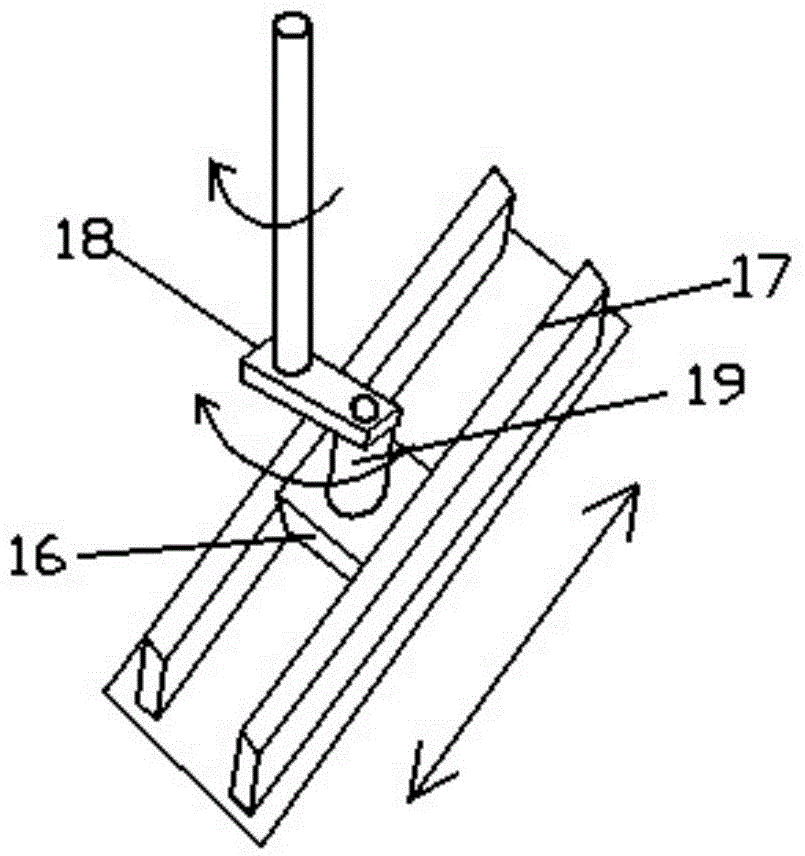

ActiveCN113479676AImprove smoothing effectEffective smoothingMechanical cleaningPressure cleaningElectric machineryRotational axis

The invention discloses intelligent fabric winding equipment with a fabric flattening function. The intelligent fabric winding equipment comprises a transportation mechanism and an intelligent fabric flattening and transporting system, and is characterized in that the transportation mechanism comprises a bracket, a treatment box is arranged at the rear half part of the upper part of the bracket, the treatment box comprises a front panel, a display screen is installed on the left side face of the treatment box, a first pressing roller is arranged on the left side of the treatment box, a plurality of induction bags are arranged on the surface of the first pressing roller, a first rotating shaft is arranged in the middle of the first pressing roller, a first motor is arranged at one end of the first pressing roller, the first rotating shaft is fixedly connected with a rotating shaft of the first motor, a first sliding rail is arranged in the front panel, a movable bearing is slidably connected into the first sliding rail, and the movable bearing comprises an outer ring, an inner ring and balls. The intelligent fabric winding equipment has the advantages of being high in practicability and capable of automatically conducting different grades of treatment on the basis of fabric textures and wrinkle degrees so as to enhance the flattening effect.

Owner:NANTONG SKIMMED GAUZE

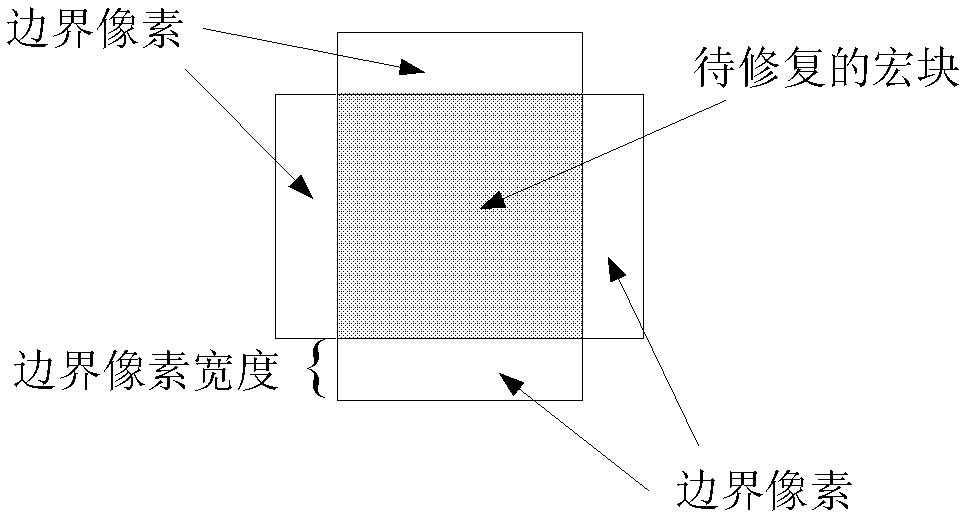

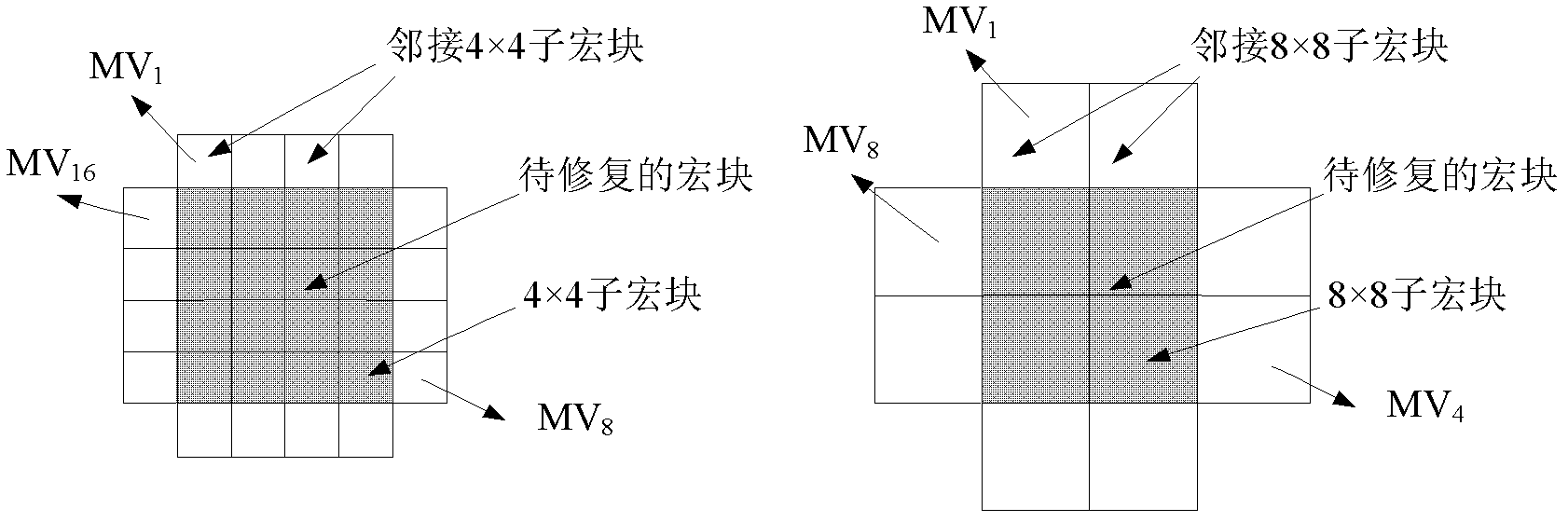

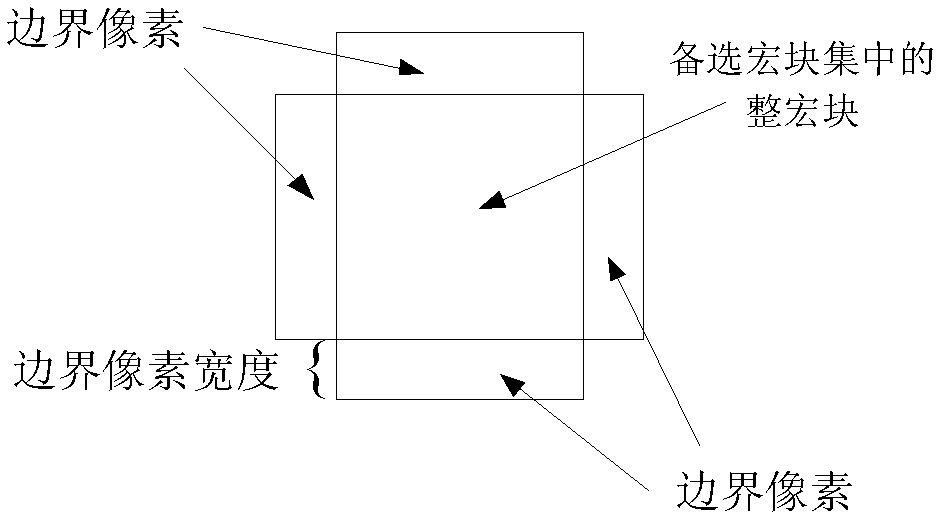

Method for hiding video errors by using linear programming model

InactiveCN102325258AWeighted result is excellentEffective smoothingTelevision systemsDigital video signal modificationObjective qualityMotion vector

The invention discloses a method for hiding video errors by using a linear programming model, belonging to the field of video image processing. The method comprises five steps of obtaining boundary pixels of a macro-block to be repaired, obtaining a motion vector set, obtaining an alternative macro-block set and a boundary set, obtaining the alternative macro-block set and the boundary set, and obtaining a weighting weight by using the linear programming model. The method provided by the invention is used for obtaining the weighting weight by using a linear programming method so that a weighting result of the alternative macro-block is optimal. Furthermore, the method for hiding the video errors can be used for effectively smoothing an error area without an influence on an accurate area, and does not have requirements on a sub-block dividing manner when a video is encoded by means of compensatively considering relativity between motion vectors and pixels around the macro-block to be repaired. The method provided by the invention has a moderate processing speed and the capability of improving a subjective quality and an objective quality of a repaired image.

Owner:BEIHANG UNIV

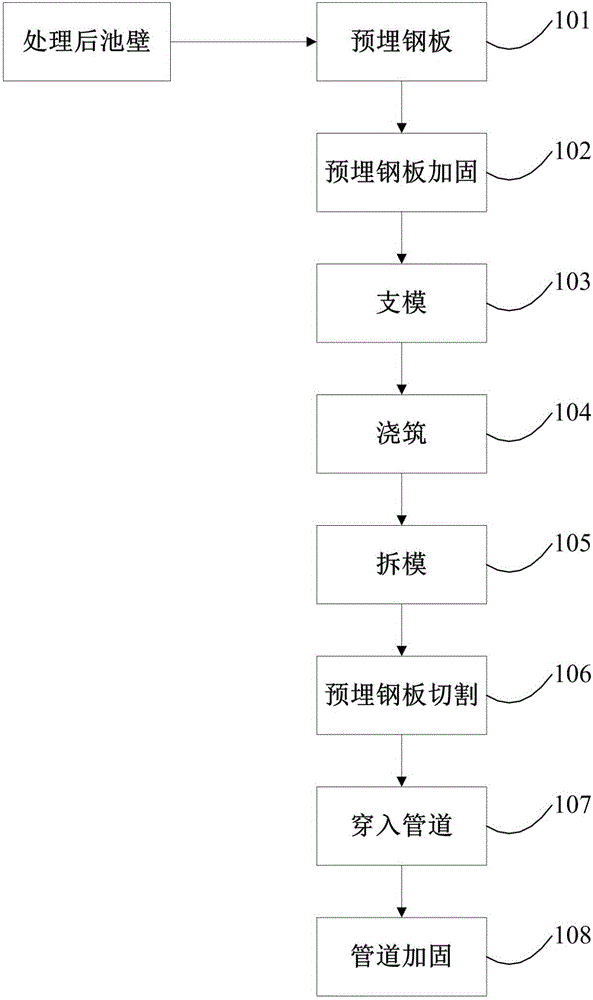

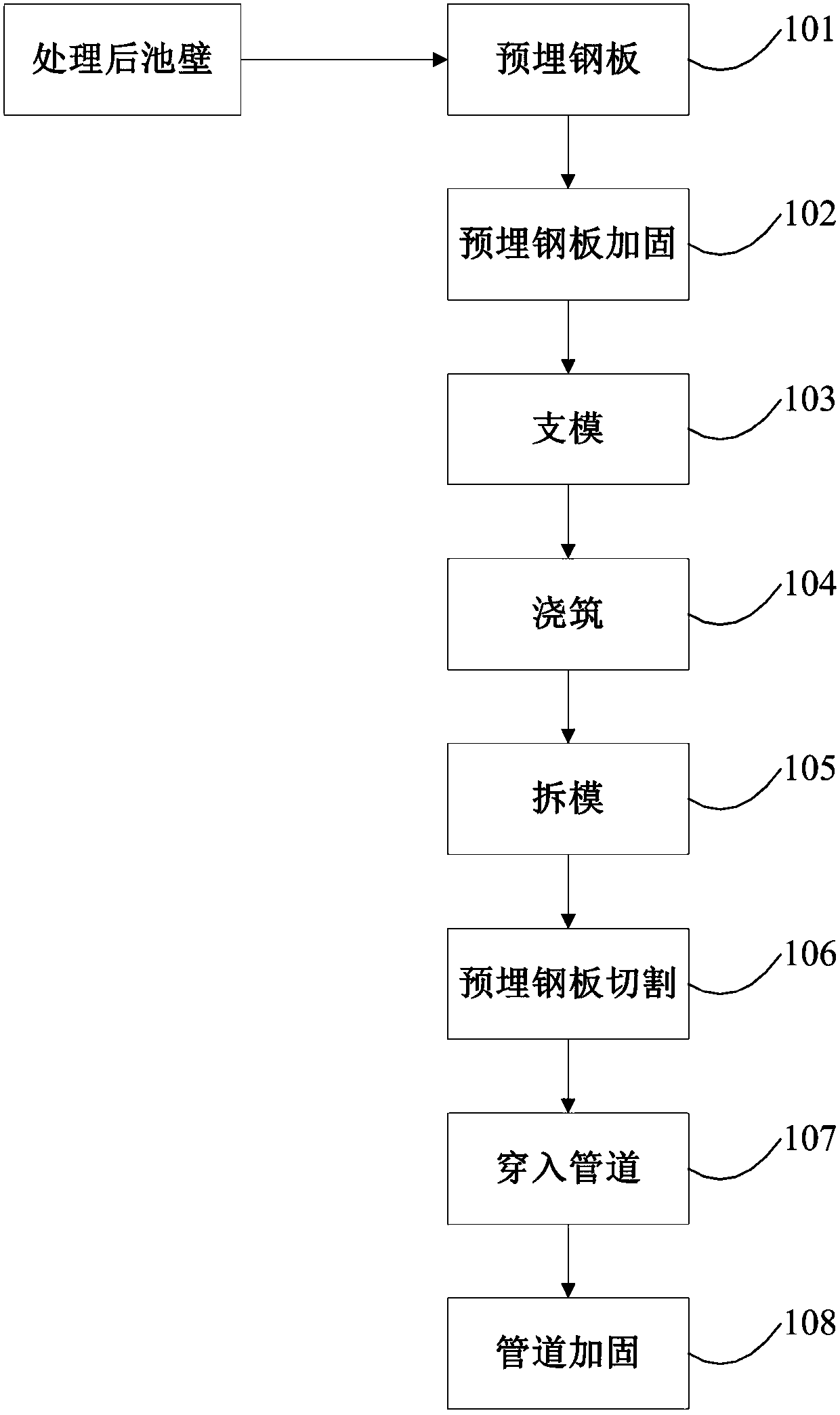

Construction method for penetrating pool by pipeline

The invention discloses a construction method for penetrating a pool by a pipeline. The construction method comprises the following steps: 1, after binding reinforcing steel bars on the pool walls of the pool, carrying out pay-off positioning on the pool wall for the reserved pipeline and embedding the pipeline in the middle of the pool wall along the vertical direction; 2, reinforcing an embedded steel plate and the reinforcing steel bars in the pool walls; 3, setting up cylindrical wood models on both sides of the pool wall with the embedded steel plate; 4, carrying out concrete pouring on the pool wall with the models set up, and reinforcing the pool wall with the embedded steel plate; 5, after the concrete on the pool wall is air dried, dismounting the wood models; 6, cutting a circular hole in the embedded steel plate; 7, enabling the pipeline to penetrate through the circular hole of the embedded steel plate and carrying out sealing treatment; and 8, reinforcing the embedded steel plate sleeved with the pipeline and the pool walls. By using the construction method disclosed in the invention, the technical problem that the water leaks from the pool wall through the gap of the pipeline in the prior art is effectively prevented, and the technical problem that the wall surface penetrated by the pipeline is bad in appearance is solved at the same time.

Owner:TIANJIN 20 CONSTR

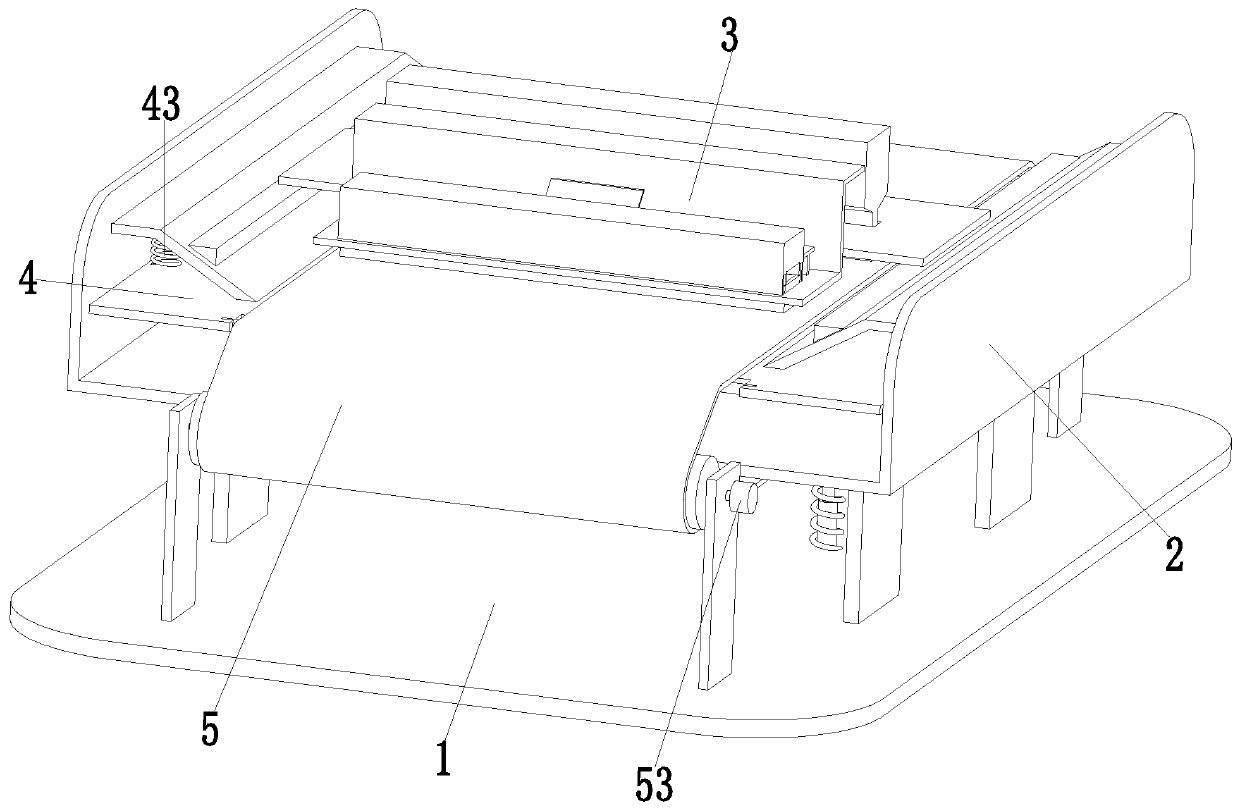

Novel cloth treatment device for garment processing

The invention discloses a novel cloth treatment device for garment processing. The device comprises a bottom plate, a cloth roller in the front-back direction is installed on the left side of the topface of the bottom plate through a first support, cloth is wound around the periphery of the cloth roller, a first power device for driving the cloth roller to rotate is arranged on the front side ofthe first support, a second support is fixedly installed in the middle of the top face of the bottom plate, a first rotating shaft in the front-back direction is installed in the middle of the front face of the second support, the second support is further provided with a second power device for driving the first rotating shaft to rotate, and three first sleeves with openings in the outer ends areannularly installed on the periphery of the front side of the first rotating shaft at equal intervals. According to the device, a first motor is adopted to drive a second pipe to rotate, a fixing needle serves as a fixing device to enable the cloth to be wound around the periphery of a roller core, the first sleeve located on the lower portion of the first rotating shaft is in a vertical state, the roller core on the lowermost portion enables the cloth to be located between the roller core and the top face of the bottom plate, the cloth can be effectively smoothed, folding and unevenness in the winding process are prevented, the length of the cloth can be controlled, and the cloth can be wound according to needs.

Owner:重庆恒升服饰制造有限公司

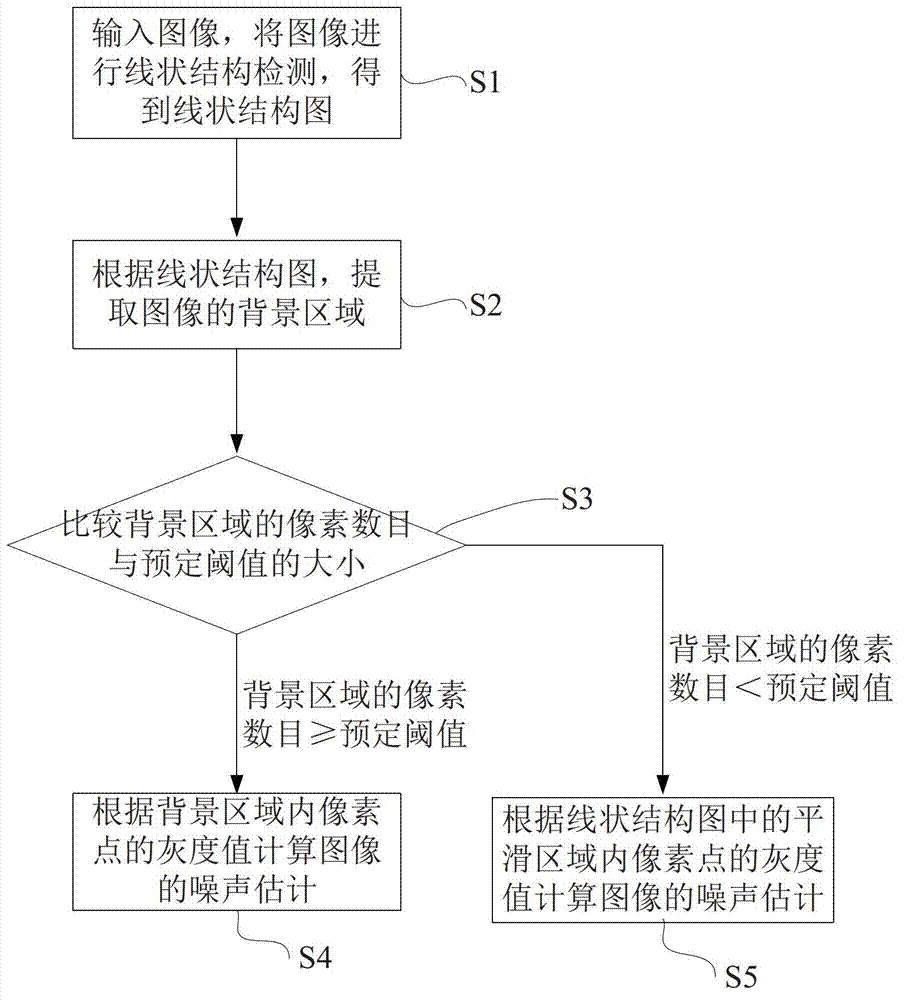

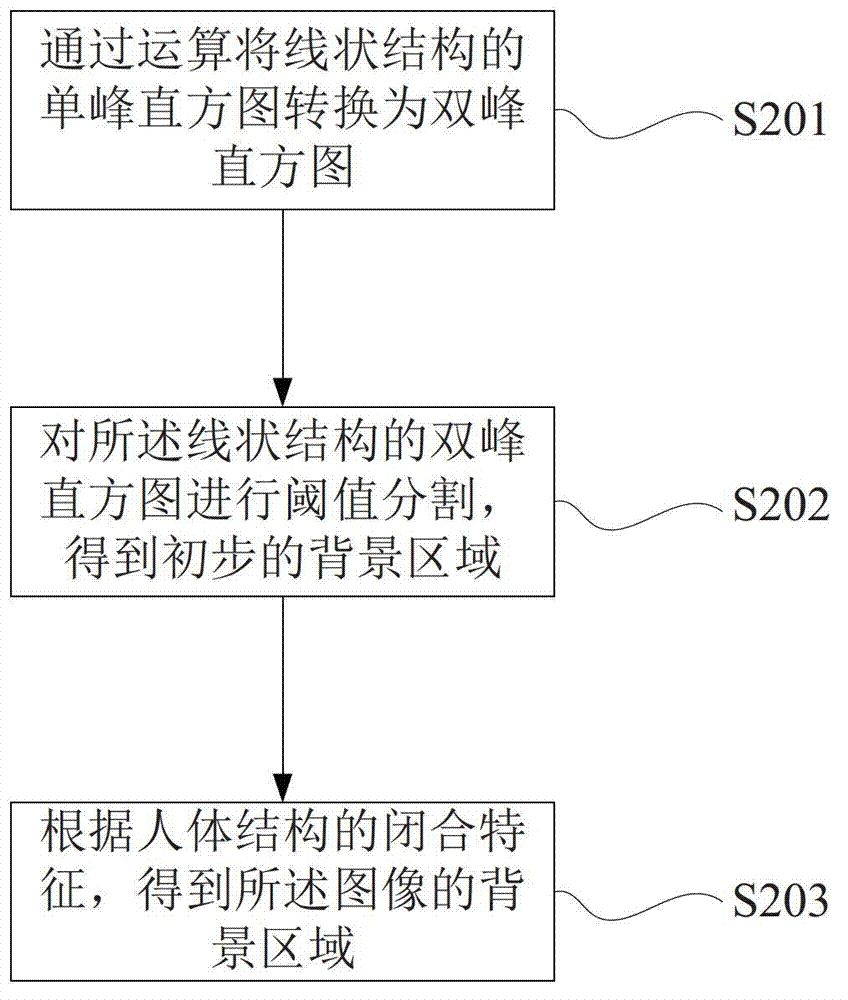

Image noise estimation method

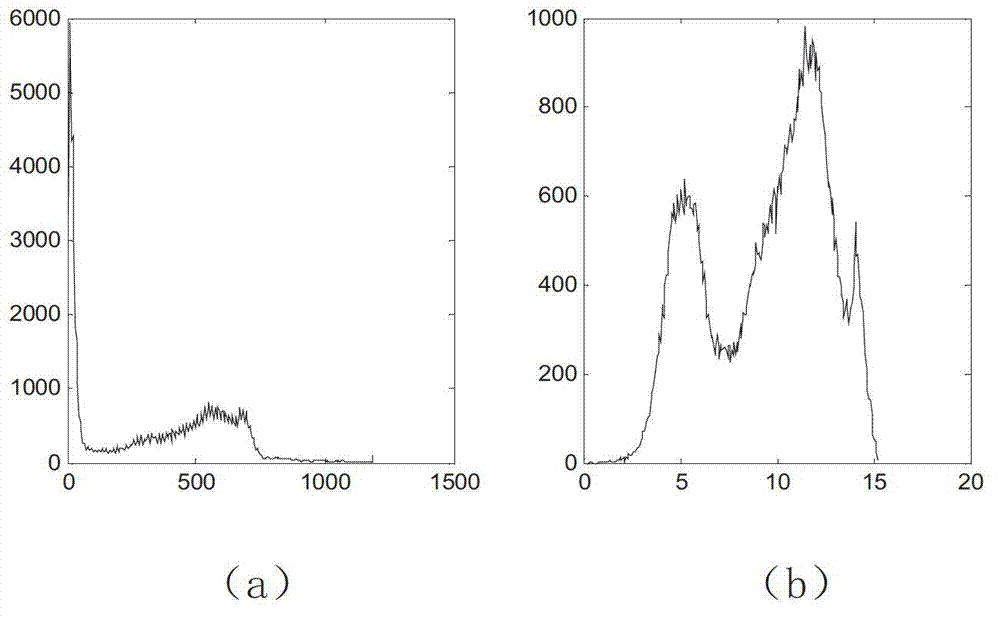

ActiveCN104103039BEffective smoothingSuppress noiseImage enhancementCharacter and pattern recognitionEstimation methodsNoise estimation

The invention provides an image noise estimation method. The image noise estimation method comprises steps: an image is inputted, linear structure detection is carried out on the image and a linear structure diagram is obtained; a background region of the image is extracted according to the linear structure diagram; the number of pixels of the background region and the size of a predetermined threshold are compared, and if the number of pixels of the background region is larger than or equal with the predetermined threshold, noise estimation of the image is calculated according to the gray value of the pixels in the background region; and if the number of pixels of the background region is smaller than the predetermined threshold, noise estimation of the image is calculated according to the gray value of the pixels in a smooth region in the linear structure diagram. The background region can be automatically, quickly and accurately extracted on the basis of linear structure detection transformation forms, noise estimation is obtained on the basis of the background region, interference of high-frequency details in the image is little, and stability and accuracy are facilitated.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

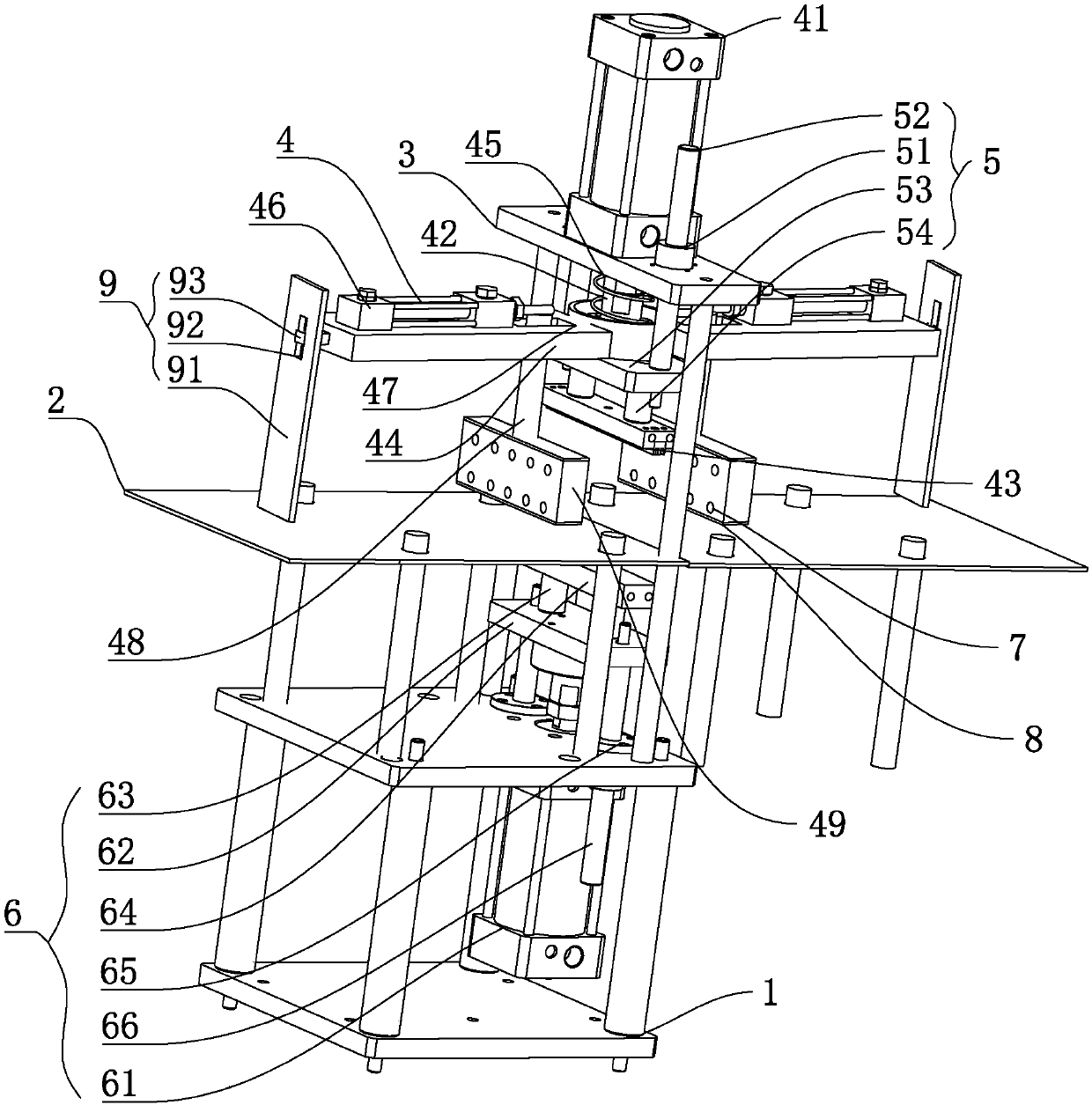

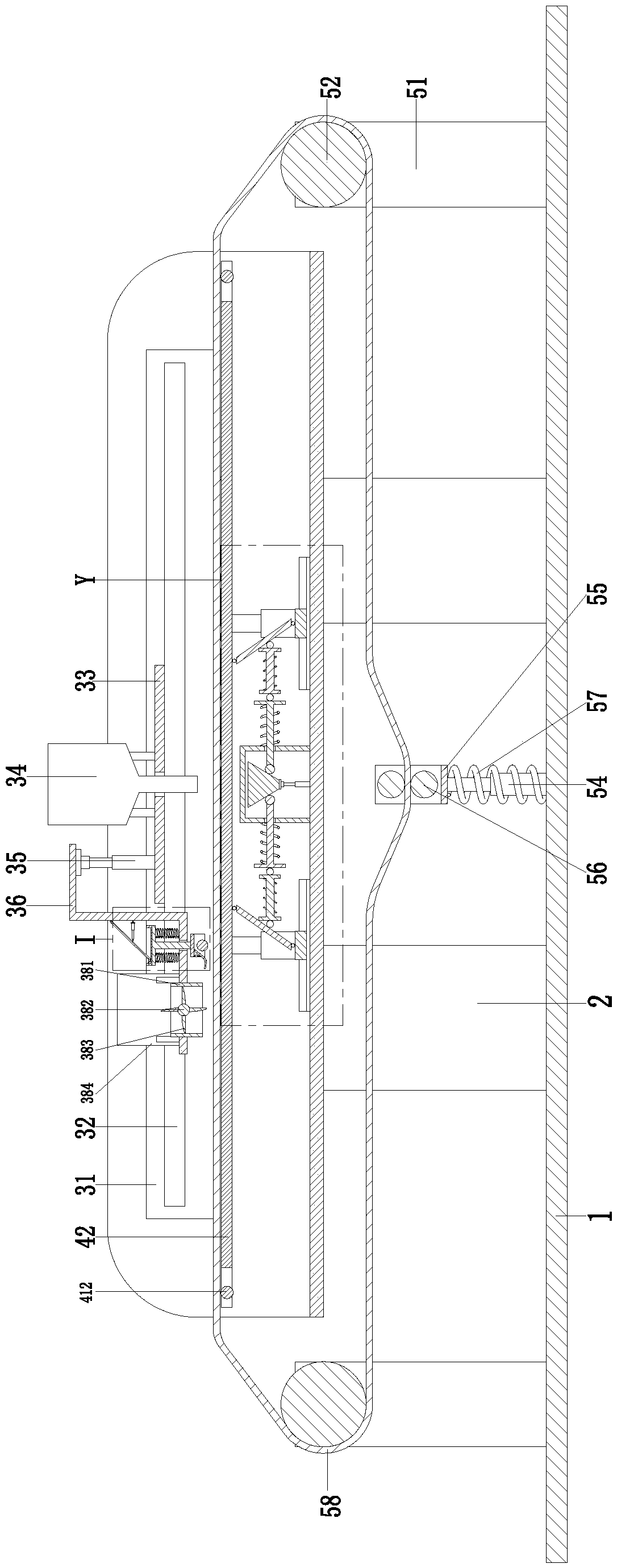

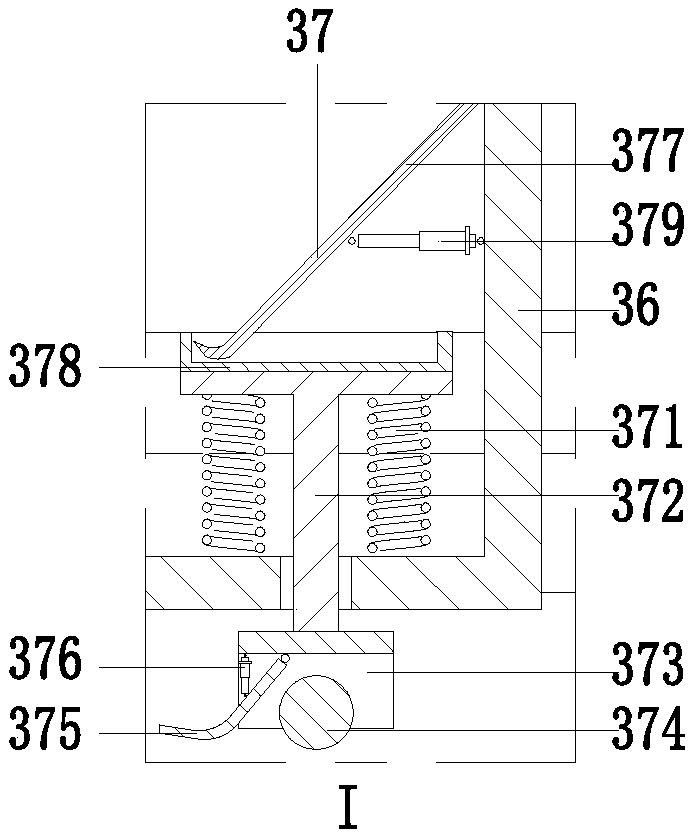

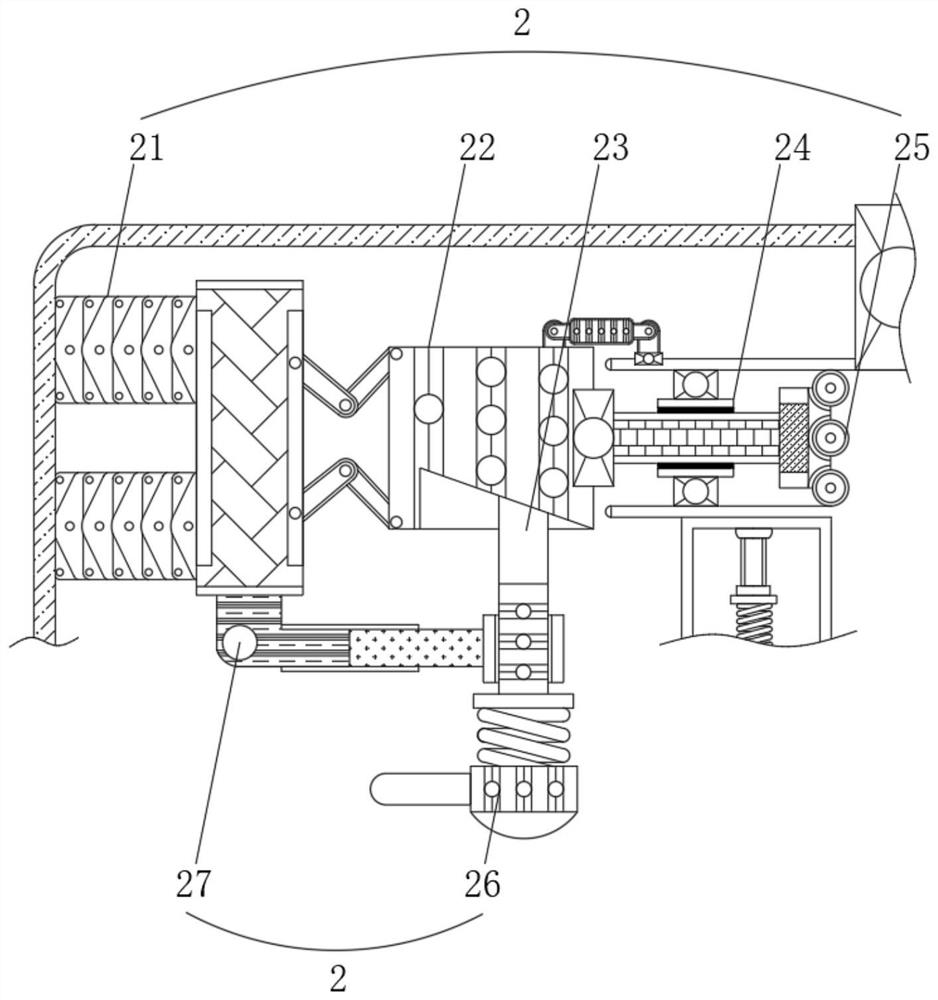

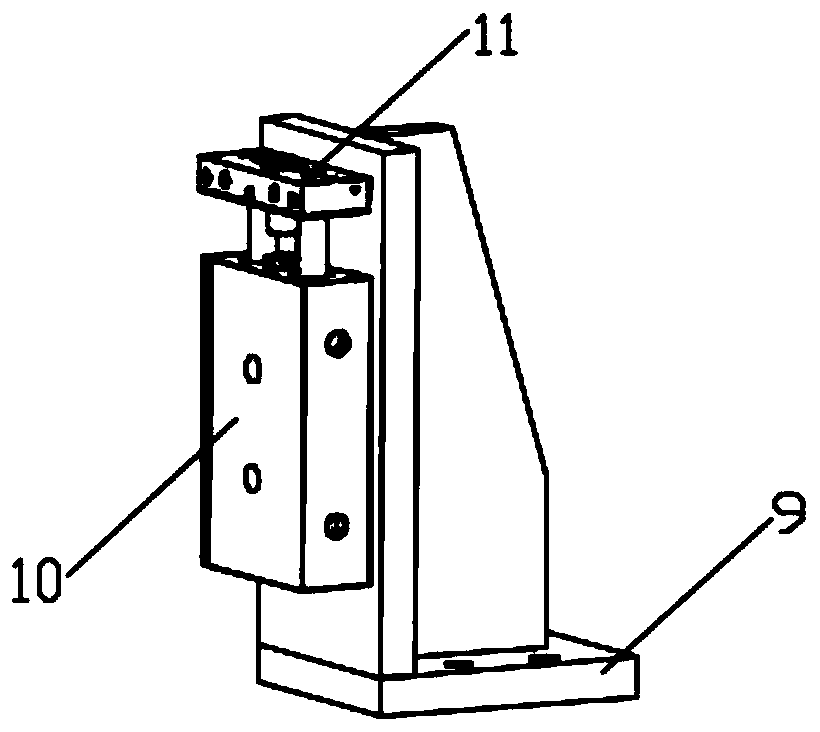

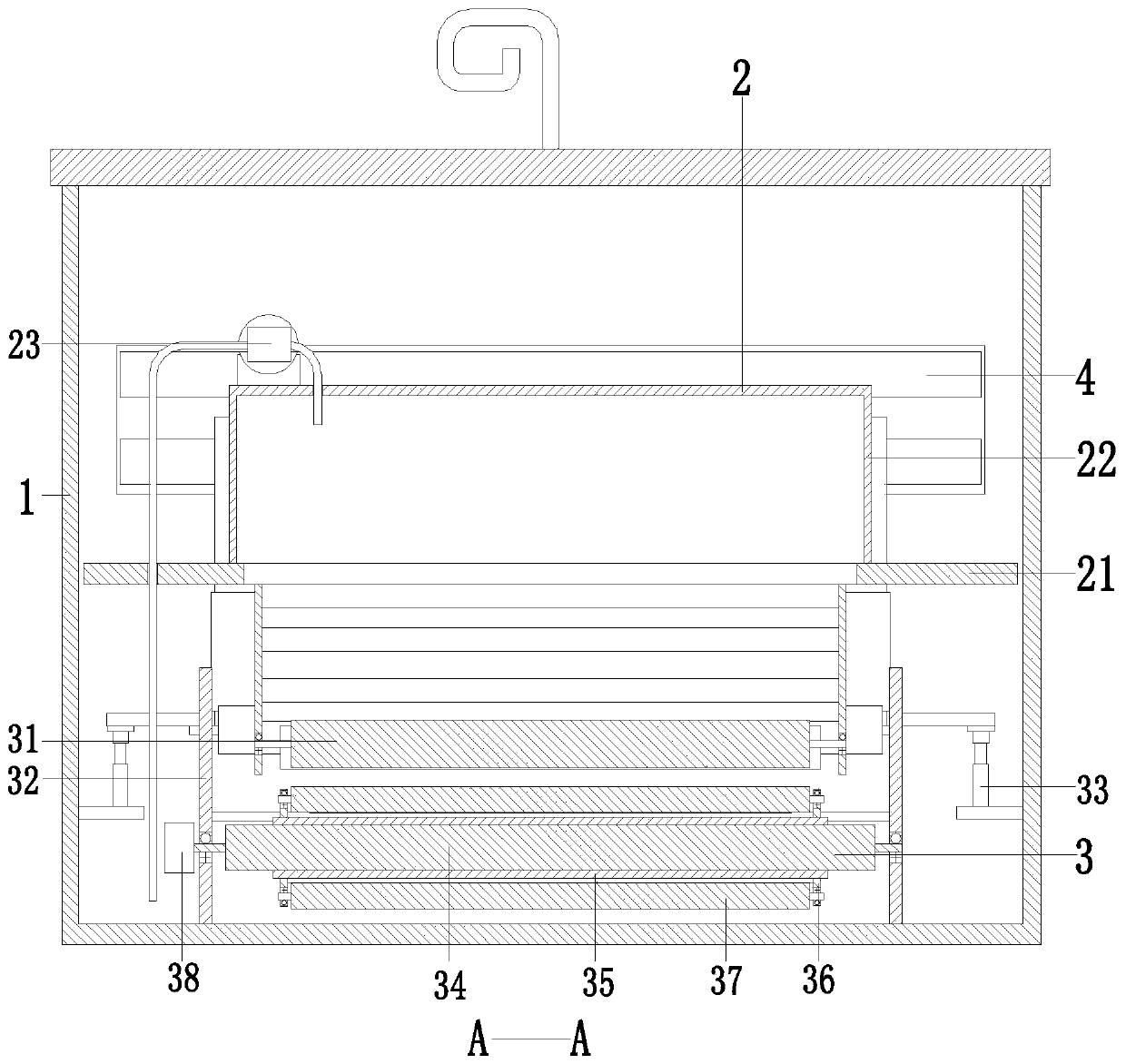

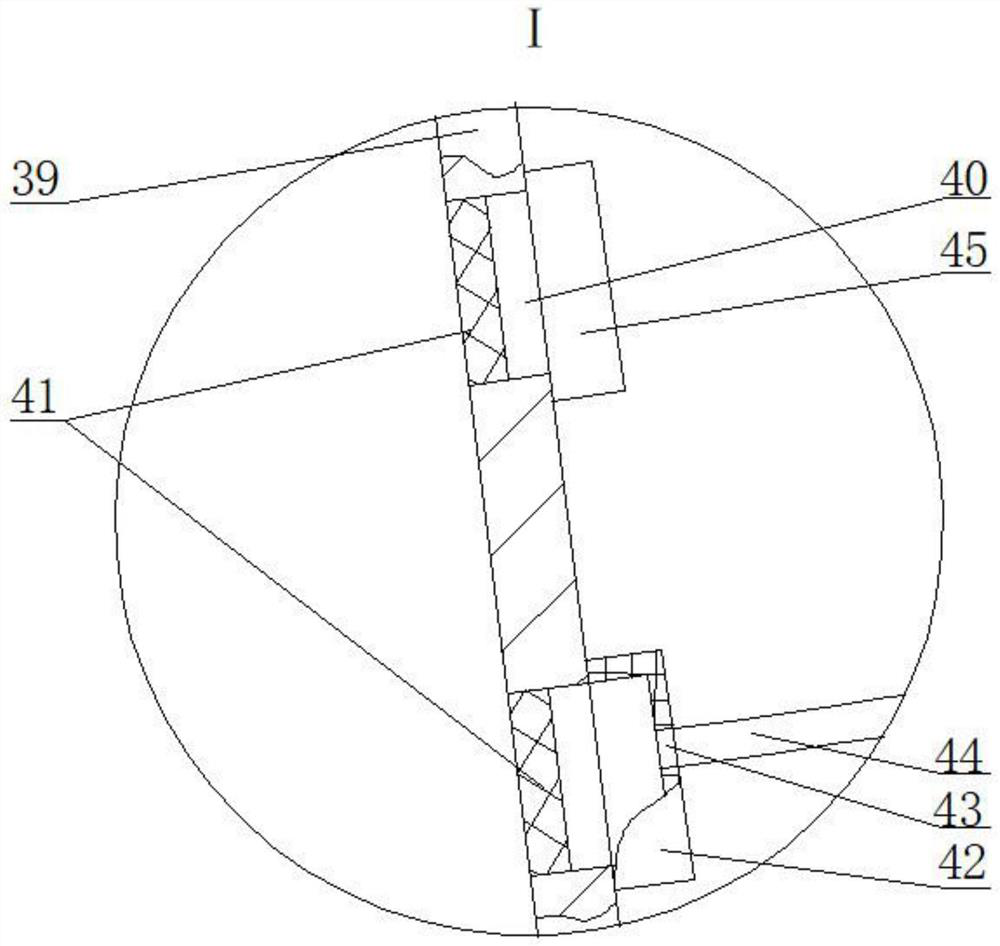

Local heating device

PendingCN107901567AReduce damageProtection securityLamination ancillary operationsLaminationVertical barArchitectural engineering

The invention discloses a local heating device, and aims at providing a local heating device capable of effectively leveling material surface. The local heating device is technically characterized bycomprising a machine frame and an operation platform, wherein the operation platform is positioned on the machine frame; a support frame is arranged on the machine frame, and is provided with a firstheating part; the first heating part comprises a first air cylinder, a telescopic rod, a first heating plate, a transverse rod, a spring, a pushing air cylinder, a groove opening, a vertical rod and an extruding plate, the first air cylinder is positioned on the support frame, the telescopic rod is positioned at an outlet of the first air cylinder and penetrates through the support frame, the first heating plate is fixedly arranged at one end, away from the first air cylinder, of the telescopic rod, the transverse rod is sheathed on the telescopic rod, the spring is positioned at the top end of the transverse rod, is connected with the support frame and is sheathed on the telescopic rod, the pushing air cylinder is positioned at one end, away from the telescopic rod, of the transverse rod,the groove opening is positioned on the transverse rod, the direction of the groove opening is uniform with the direction of the transverse rod, the vertical rod is positioned at the top end of the interior of the groove opening and is fixedly connected with an outlet of the pushing air cylinder, and the extruding plate is positioned at one end of the vertical rod and is in contact with the material.

Owner:WUXI UNITE ENERGY TECH CO LTD

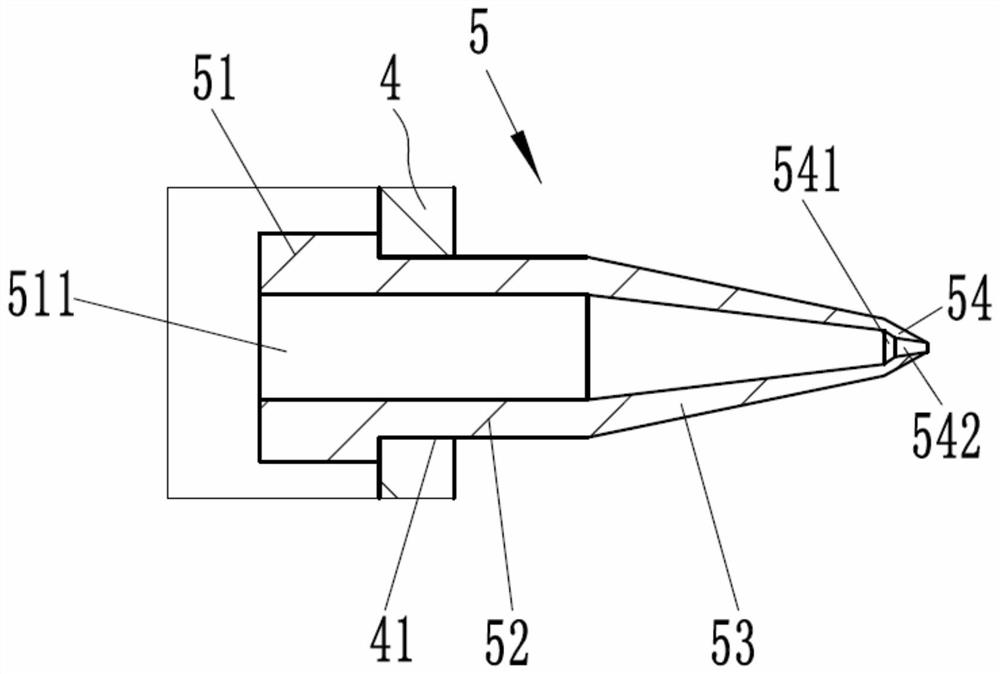

PCB board gluing device

ActiveCN111992394AImprove gluing efficiencyEasy to handleLiquid surface applicatorsSpraying apparatusEngineeringMechanical engineering

Owner:鸿安(福建)机械有限公司

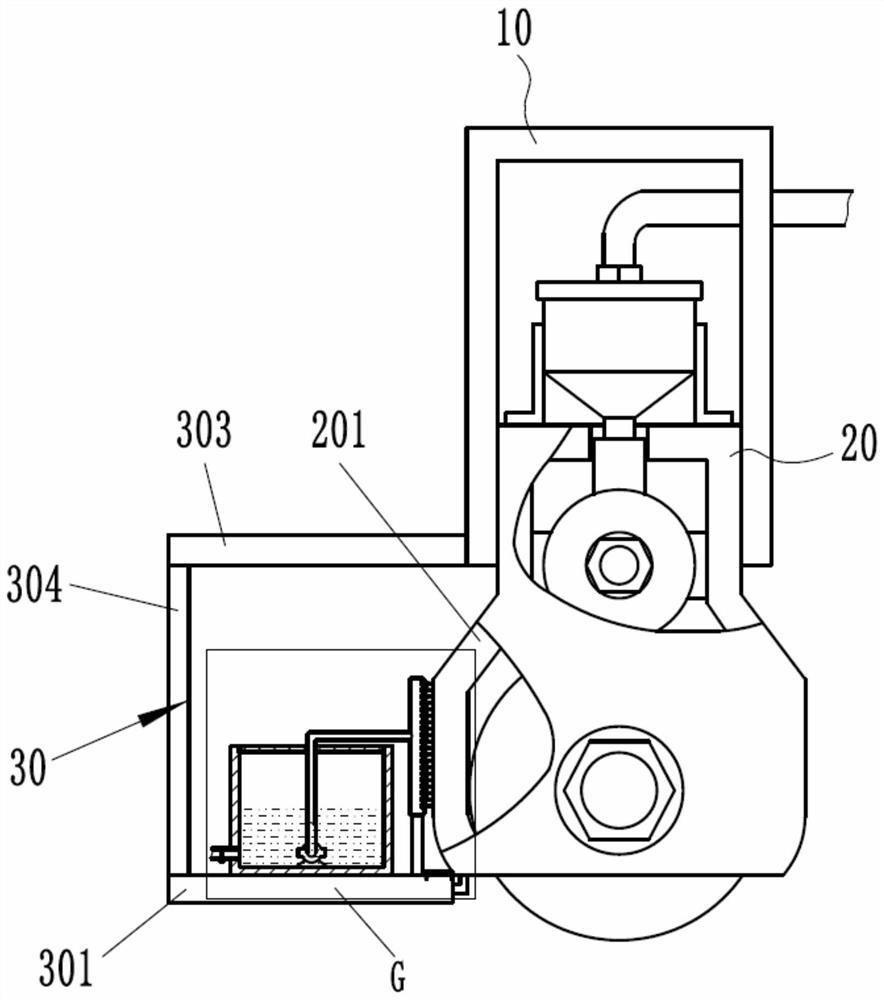

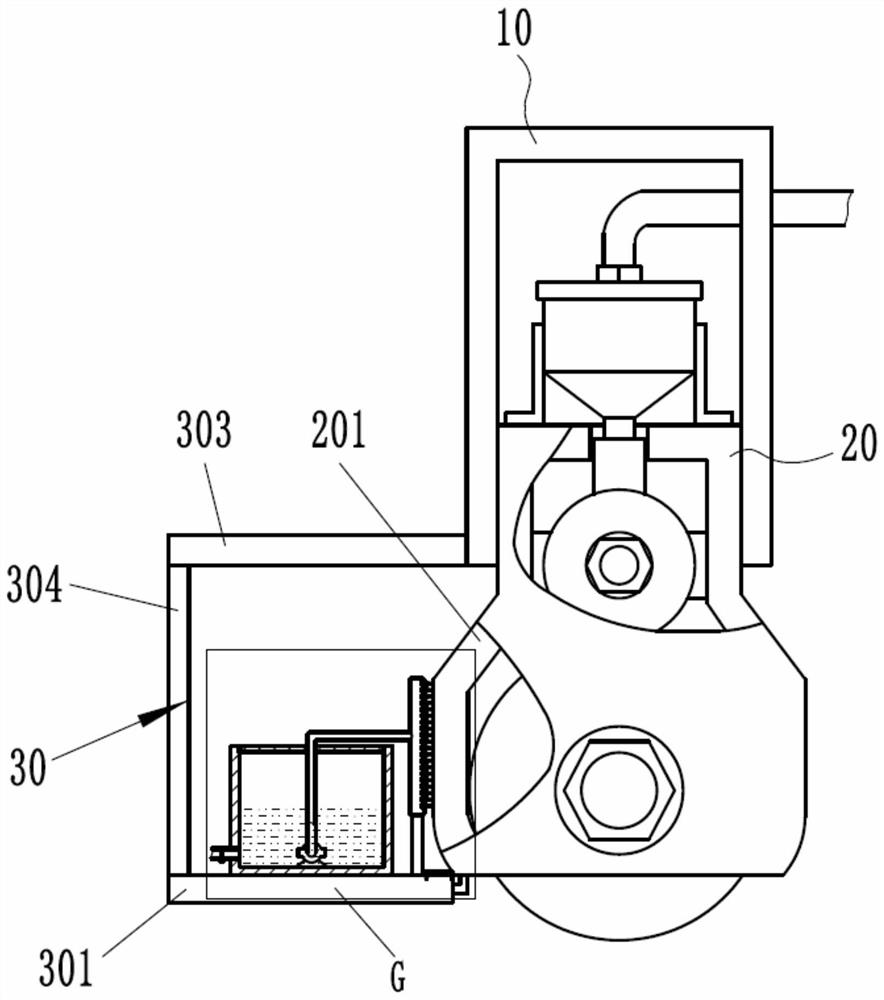

Automatic production line for granite-like marble paint synthesis

ActiveCN109046883AControl UniformityRealize the function of automatic processingLiquid surface applicatorsCoatingsWind speedRaw material

The invention mainly relates to an automatic production line for granite-like marble paint synthesis. The automatic production line comprises a base plate; a support working frame is mounted on the base plate; an adjustment spraying device is mounted between the inner walls of the support working frame; an auxiliary lifting device is mounted on the support working frame, and is connected with a driving device; and the driving device is mounted on the base plate. The automatic production line can solve the difficulties of need of manually controlling a spraying machine to spray raw materials manufactured by artificial-synthesized rock slices in the production process of traditional granite-like marble paint, need of manually controlling the spraying thickness of the raw materials, incapability of guaranteeing the spraying thickness of the raw materials due to manual control of the spraying machine, incapability of guaranteeing the spraying uniformity, long natural airing time of the rawmaterials after spraying, higher influence on the surfaces of the sprayed raw materials by the air speed generated by manual use of drying equipment, need of manually conveying the dried raw materials, high labor intensity and low working efficiency.

Owner:宁波富丽佳涂料有限公司

Full-breadth cloth supporting device of rapier jacquard loom

The invention discloses a full-breadth cloth supporting device of a rapier jacquard loom. The device includes a box body, a motor is fixedly connected to the outer wall of one side of the box body through bolts, a first leftward rotated lead screw is rotatably connected to one end of the motor through a rotating shaft, a first rightward rotated lead screw is welded to the end, away from the motor,of the first leftward rotated lead screw, and the first leftward rotated lead screw is screwed into a first extrusion base through a thread; a smooth roller is installed on the inner wall of one sideof the first extrusion base, and the first rightward rotated lead screw is screwed into a second extrusion base through a thread. On the one hand, a full-bread cloth is effectively flattened by a transverse tensile force generated when the smooth roller moves towards two sides, the problem that the full-breadth cloth is creased and folded during conveying is avoided, it is ensured that the full-breadth cloth stays at a smooth and straight state when entering the jacquard loom, and the quality of jacquard patterns is improved; on the other hand, through the transverse tensile force, transversevibration of a part of the full-breadth cloth can be offset to avoid broken picks of the full-breadth cloth.

Owner:ZHEJIANG XINGFEIER TECH CO LTD

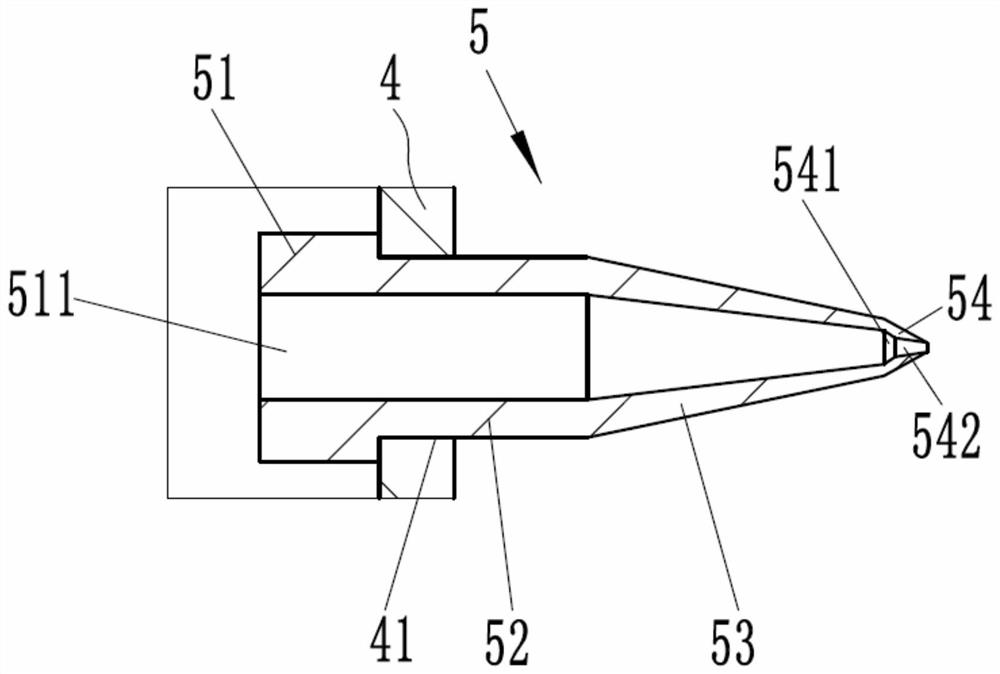

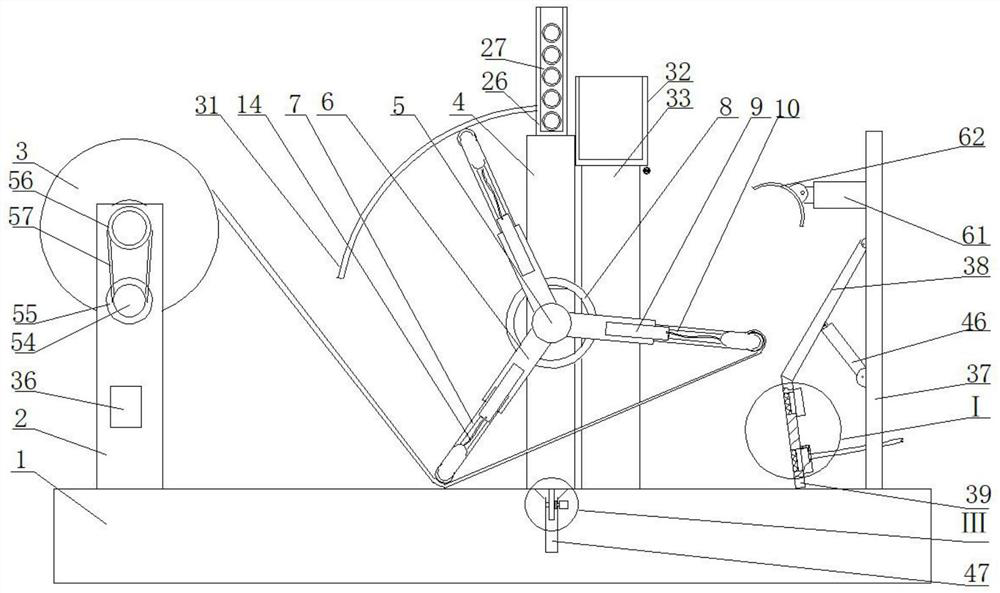

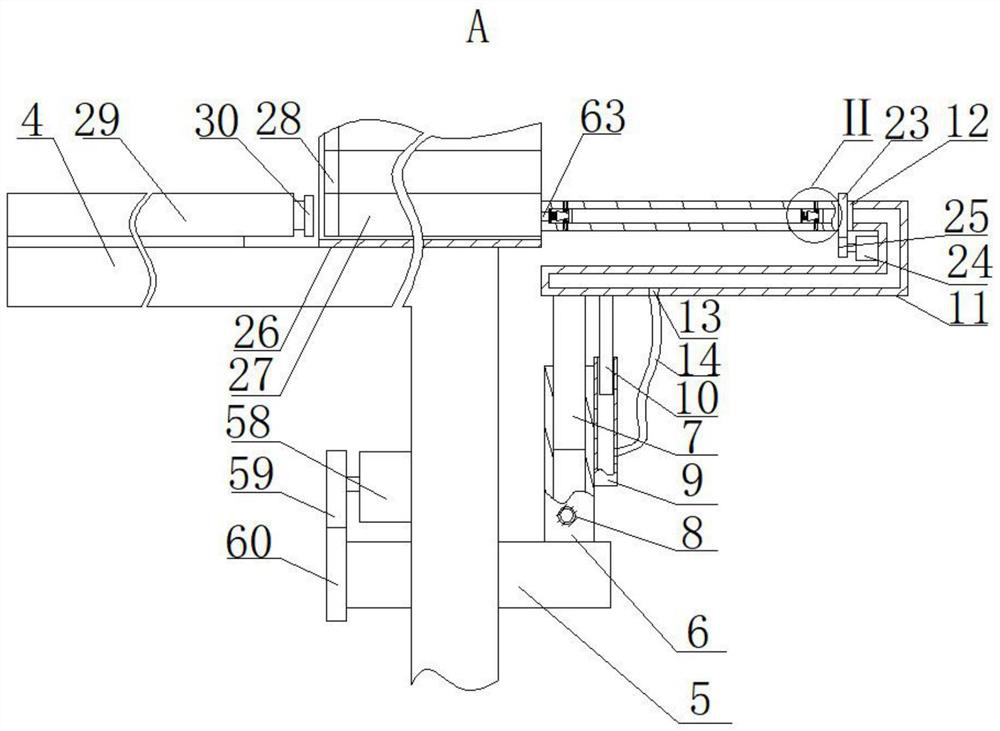

A pcb board gluing device

ActiveCN111992394BEffective smoothingImprove gluing efficiencyLiquid surface applicatorsSpraying apparatusEngineeringMechanical engineering

Owner:鸿安(福建)机械有限公司

Bidirectional hot working process for hollow fiber membrane lining pipe

The invention relates to the technical field of fiber membrane lining tubes, in particular to a bidirectional hot working process for a hollow fiber membrane lining pipe, which comprises a heating mechanism and a driving mechanism, the heating mechanism comprises a workbench, a hollow hot copper rod is fixedly connected in the workbench, a porcelain eye is fixedly connected to the lower surface of the hollow hot copper rod, and a steel ball is movably connected to the interior of the porcelain eye, a core rod is fixedly connected to the outer surface of the steel ball, the driving mechanism comprises a fixing block, and an adjusting block is movably connected to the outer surface of the fixing block. When an ejector rod slides downwards in a limiting sleeve, a protruding block exerts pushing force on a protruding plate, the protruding plate is arranged in a protruding mode, at the moment, the protruding plate pushes a connecting column to slide towards the interior of a fixing shell, at the moment, the connecting column exerts extrusion force on a liquid storage bag, and the liquid storage bag is stressed to extrude out marking liquid in the liquid storage bag. And a connecting pipeline is sprayed to the deformed position of the lining pipe, so that later searching by workers is facilitated.

Owner:宁国市绿水源环保科技有限公司

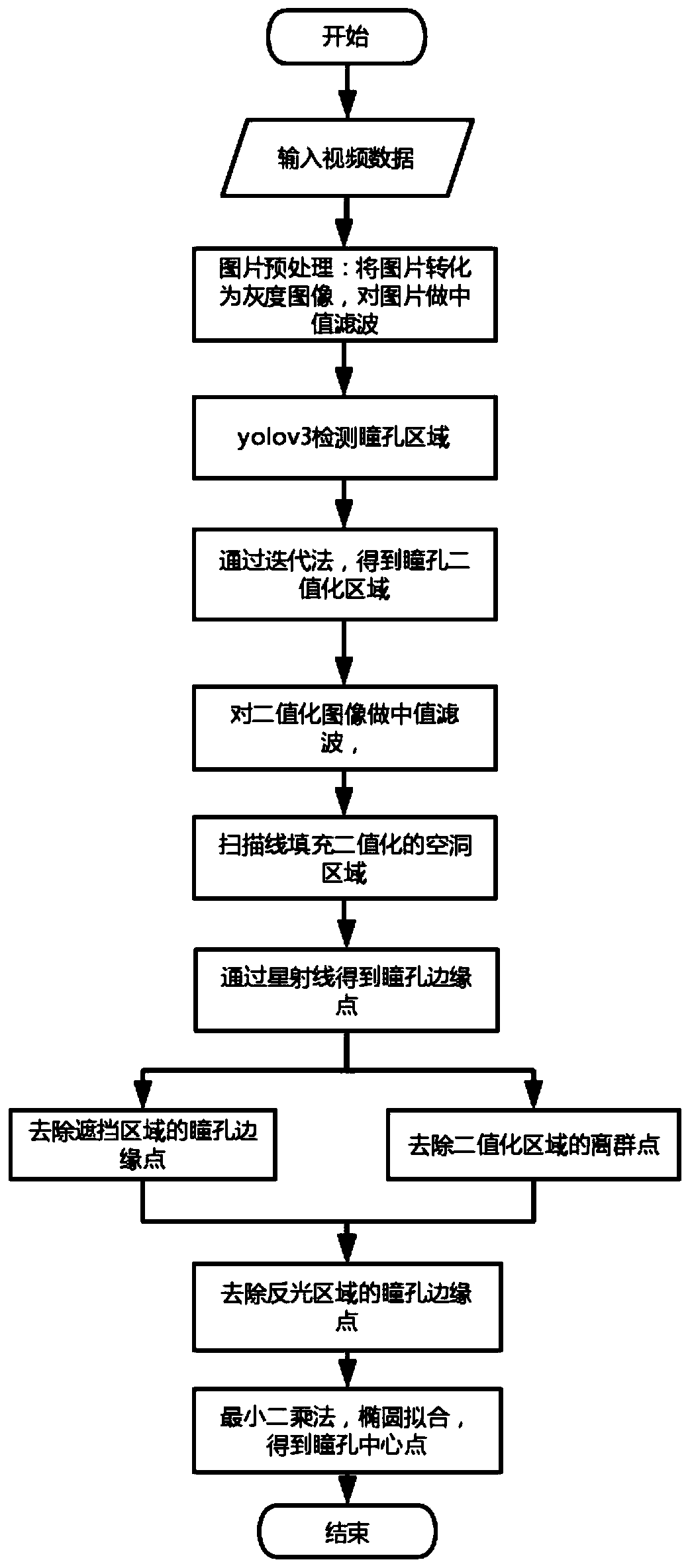

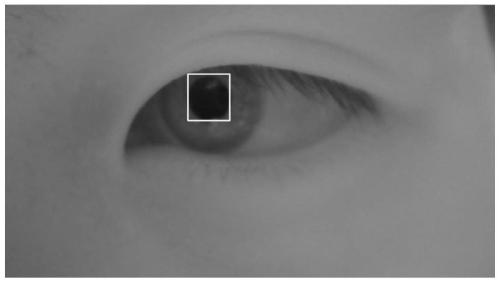

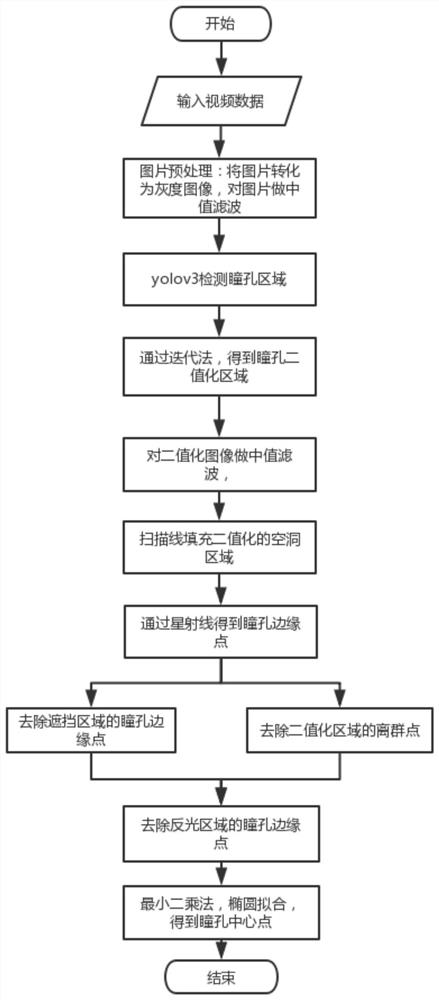

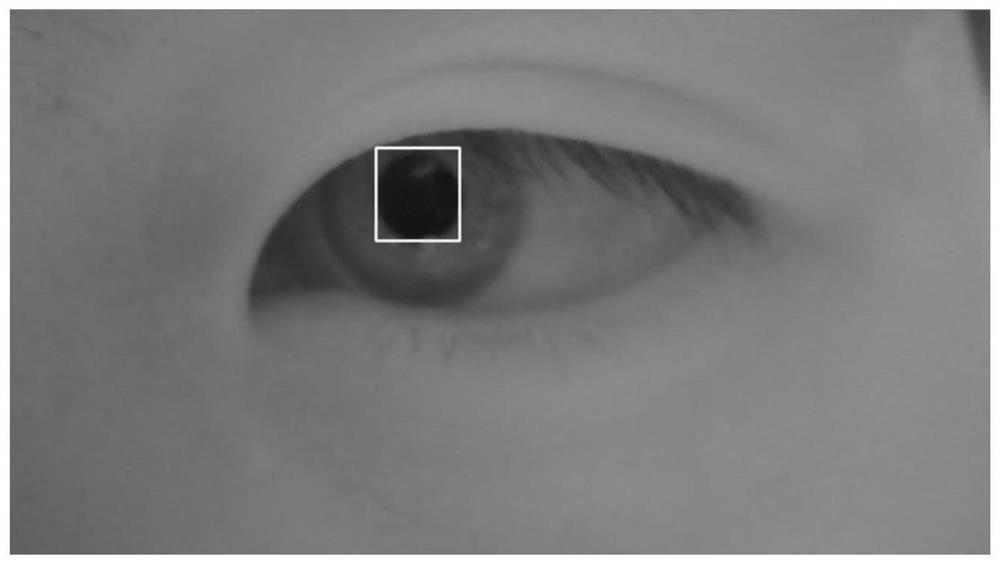

Pupil center positioning method based on star rays

ActiveCN111369496APrecise positioningEasy to detectImage enhancementImage analysisImaging processingOphthalmology

The invention belongs to the technical field of image processing, and particularly relates to a pupil center positioning method based on star rays. The method comprises the following steps: preprocessing a picture, detecting a pupil region through a star ray algorithm, obtaining a binarized threshold value in an ROI region through an iterative method, optimizing the binarized pupil region, and eliminating star ray edge point errors. According to the invention, the pupil center point under the shielding condition can be accurately detected. According to the method, the requirements of real-timeperformance and robustness are better met.

Owner:ZHONGBEI UNIV

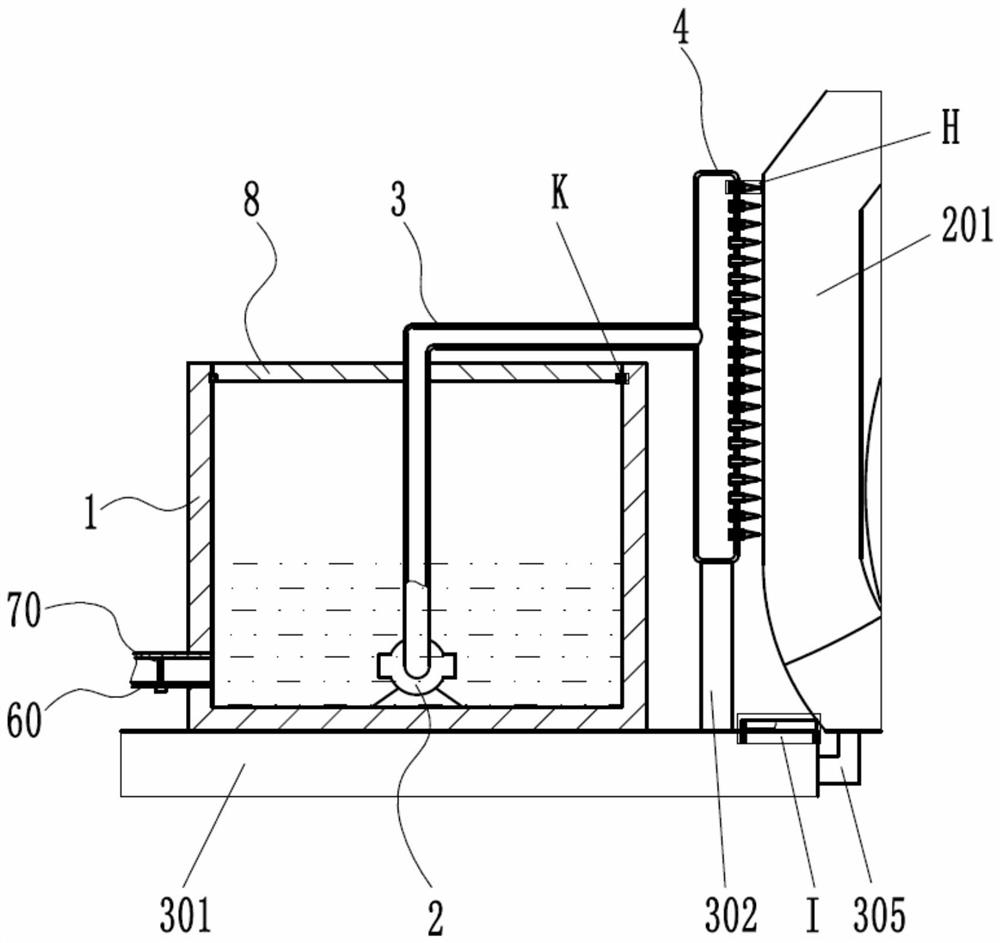

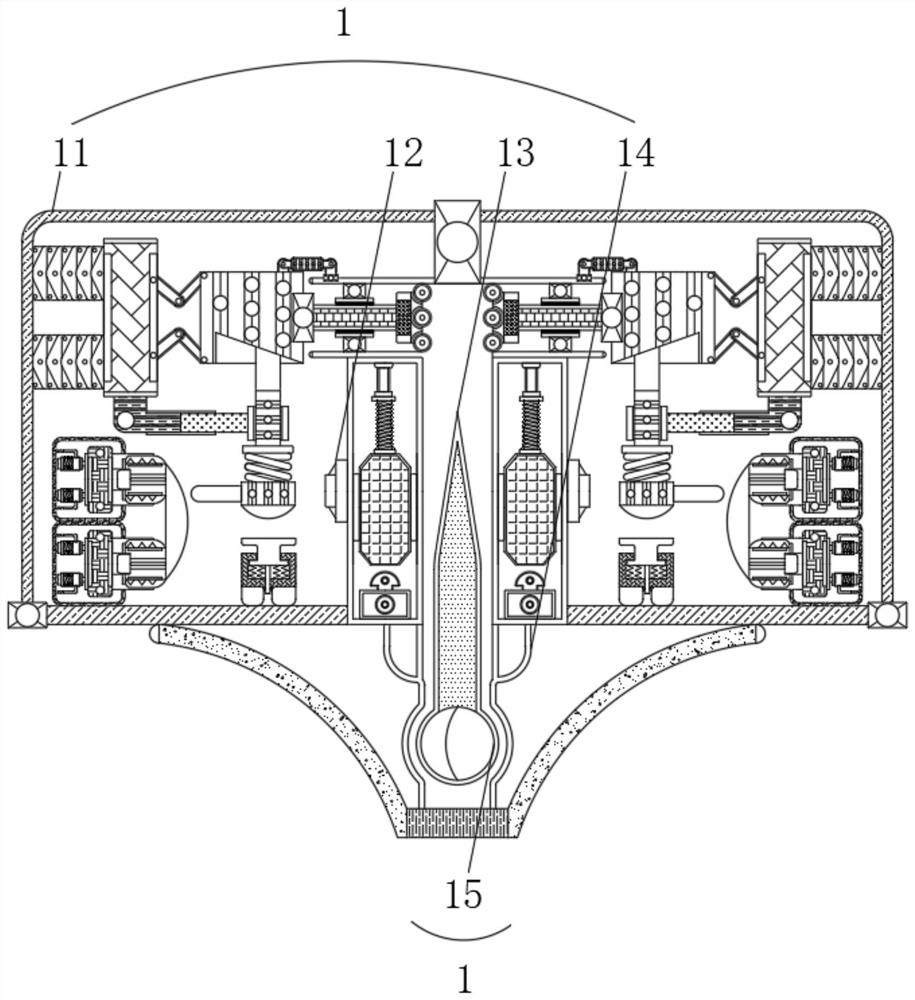

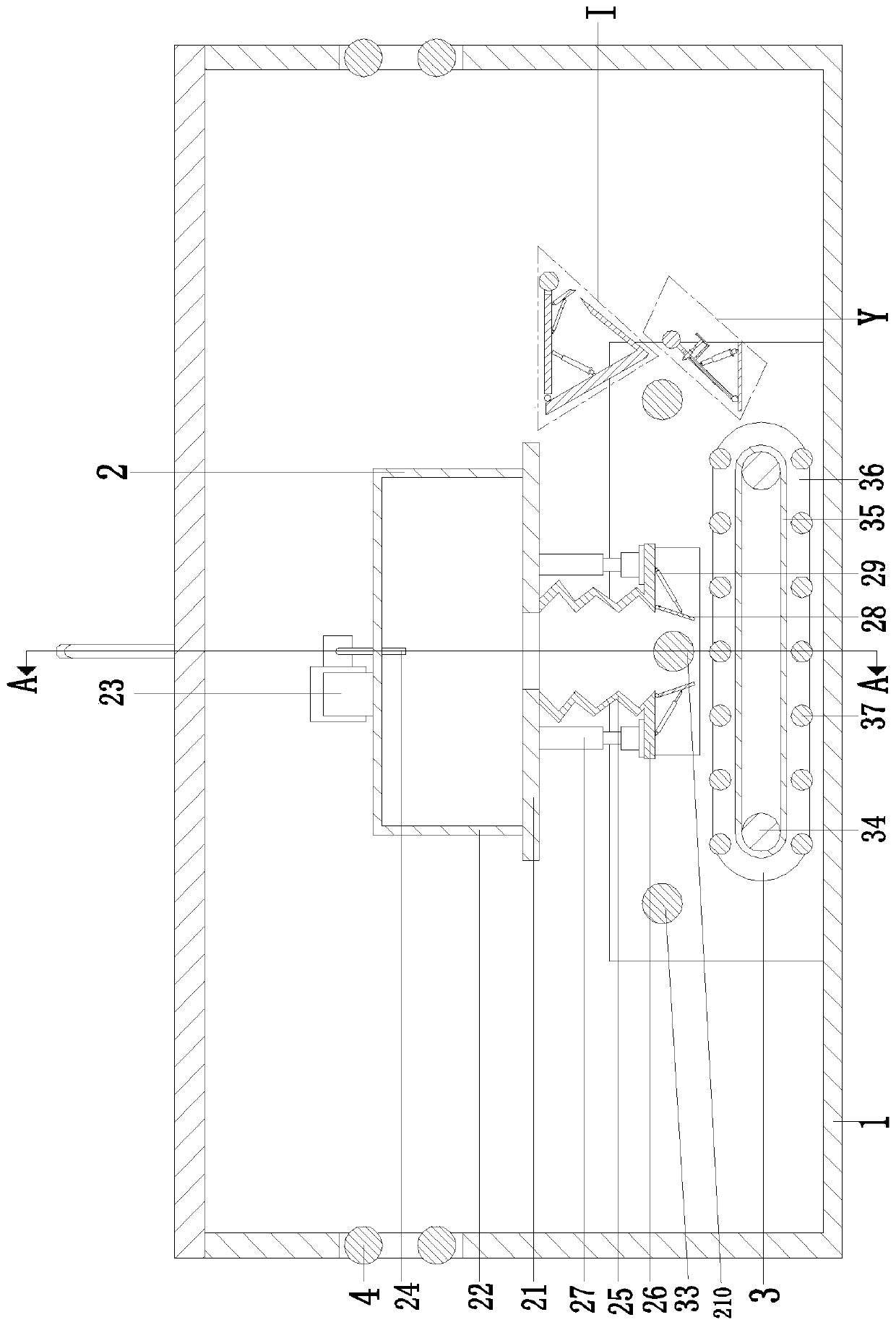

A steel plate galvanizing production line and the galvanizing process of the production line

ActiveCN108914033BInhibition thicknessIncrease labor intensityHot-dipping/immersion processesProduction linePipe

The invention relates to a steel pipe galvanization production line and a galvanization technology of the production line. The production line comprises a galvanization work box, the upper end face ofthe galvanization work box is of a detachable structure, the front side and the rear side of the galvanization work box are provided with work grooves, two operation assisting rollers are arranged inthe work grooves through bearings, the two operation assisting rollers achieve the effects of guiding and movement assisting on steel plates when the steel plates penetrate through the galvanizationwork box, and a coating device is arranged on the inner wall of the upper end of the galvanization work box. The problems that when galvanization steel plates are in the galvanization working procedure in the prior art, the steel plate galvanization thickness cannot be effectively controlled, galvanization layers on the surfaces of the steel plates are not uniform, the labor intensity is large, precision is poor, and the working efficiency is low are solved, the function of efficient and accurate production of the steel plate galvanization technology can be achieved, manual operation is not needed, and the production line has the advantages that the labor intensity is low, accuracy is high, and the working efficiency is high.

Owner:湖南恒力通电气设备科技有限公司

A fabric anti-wrinkle winding device

The invention discloses a fabric wrinkle-proof reeling device. According to the device, a rack is movably arranged on a base; the rack and a guide roller on the rack are driven to operate through a drive mechanism to generate reciprocating friction force on the grey cloth surface to balance the grey cloth surface tension to efficiently smoothen a grey cloth, so that the generation of wrinkles on the grey cloth edges caused by repeat stacking is prevented; through the additional arrangement of a wrinkle-proof guide roller with thread lines, when the wrinkle-proof guide roller rotates, acting forces, relative to the grey cloth, towards two sides can be generated to increase left and right stretching forces of the grey cloth surface to avoid the generation of the wrinkles at the inner part of the grey cloth. When the wrinkle-proof guide roller acts, and the rack is moved simultaneously, the stretching force is compensated and balanced through the movement amount to avoid the wrinkles generated by repeat stacking of the edges and the inner part, so that the grey cloth quality is guaranteed on the premise that the reeling efficiency is improved, the follow up dyeing operation is facilitated, and the dyeing quality is improved.

Owner:苏州宜新织造有限公司

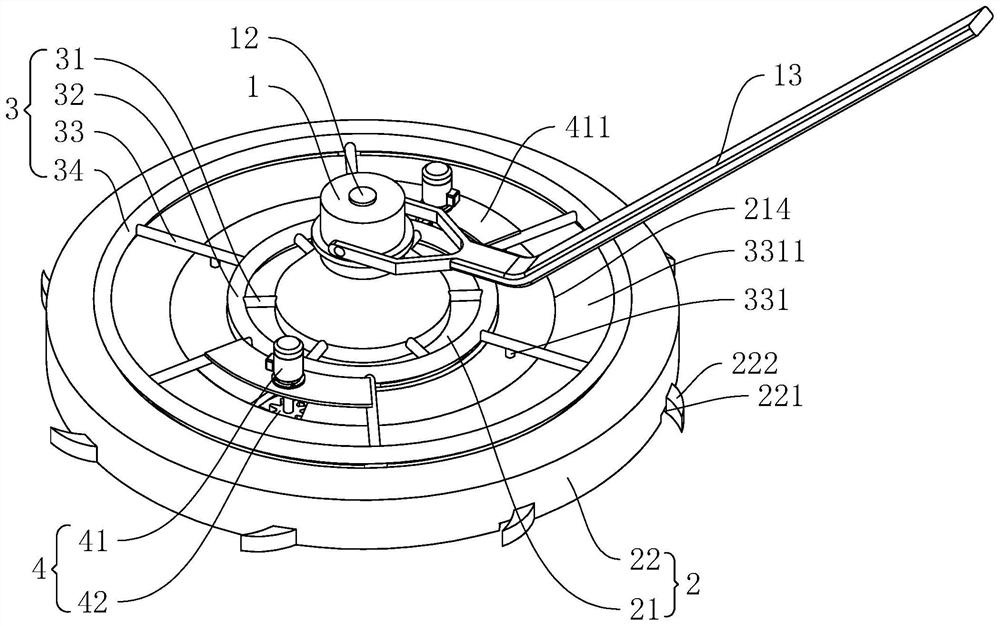

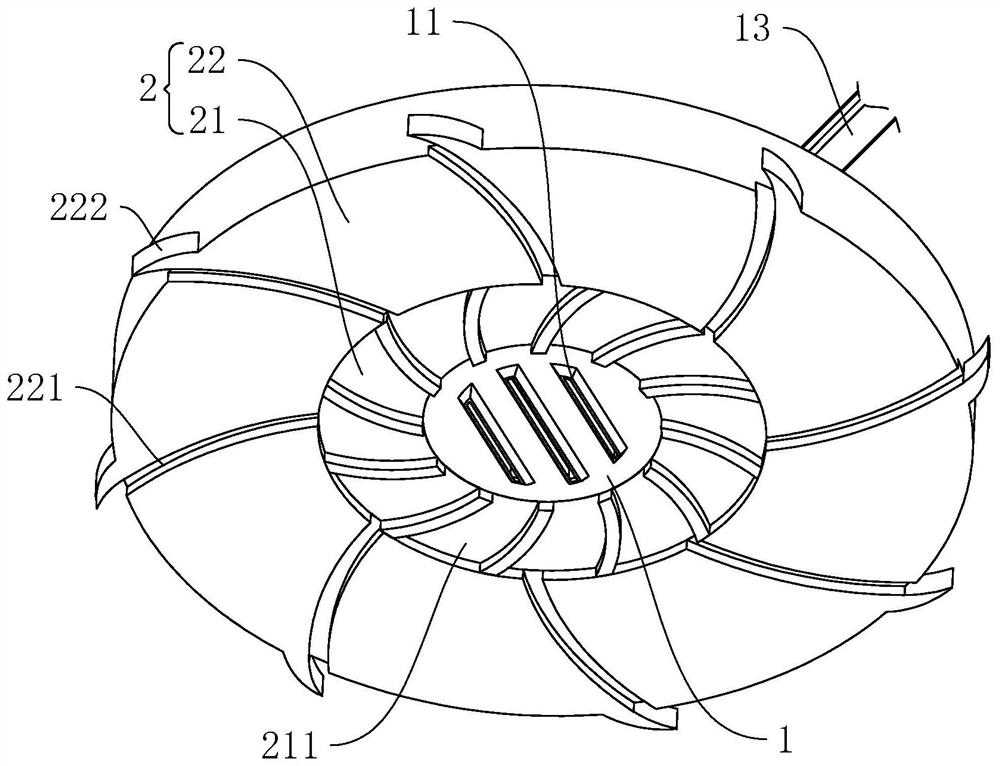

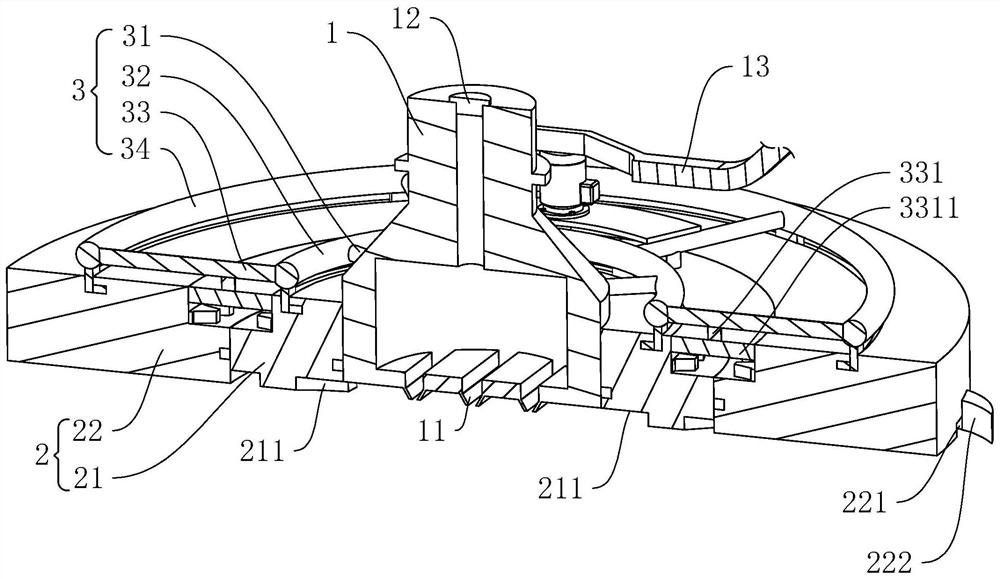

Concrete trowelling machine

InactiveCN106335127AEffective smoothingReduce pollutionCeramic shaping apparatusElectric machineryArchitectural engineering

The invention discloses a concrete trowelling machine. The concrete trowelling machine comprises a trowelling cabinet and a purification cabinet arranged at the bottom of the trowelling cabinet. A base is arranged between the trowelling cabinet and the purification cabinet. A base plate is arranged on the surface of the base. A rotary shaft is arranged in the middle of the base plate. A support is connected to the top of the rotary shaft. Concrete is fixed to the surface of the support. The two sides of the concrete are correspondingly provided with a first water delivery pipe and a second water delivery pipe. The surface of the first water delivery pipe and the surface of the second water delivery pipe are each provided with multiple high-pressure water valves. The top of the first water delivery pipe and the top of the second water delivery pipe are correspondingly connected with a first lifting air cylinder and a second lifting air cylinder. The first lifting air cylinder and the second lifting air cylinder are connected to the top of the trowelling cabinet. According to the concrete trowelling machine, the concrete is put on the support, the rotary shaft is driven by a motor to rotate, ascending and descending of the water delivery pipes are controlled through the lifting air cylinders, the concrete is trowelled in an omnibearing and three-dimensional manner, and it is guaranteed that the concrete in different shapes and of different specifications can be trowelled effectively.

Owner:WUXI CHUANGNENG POWER TECH CO LTD

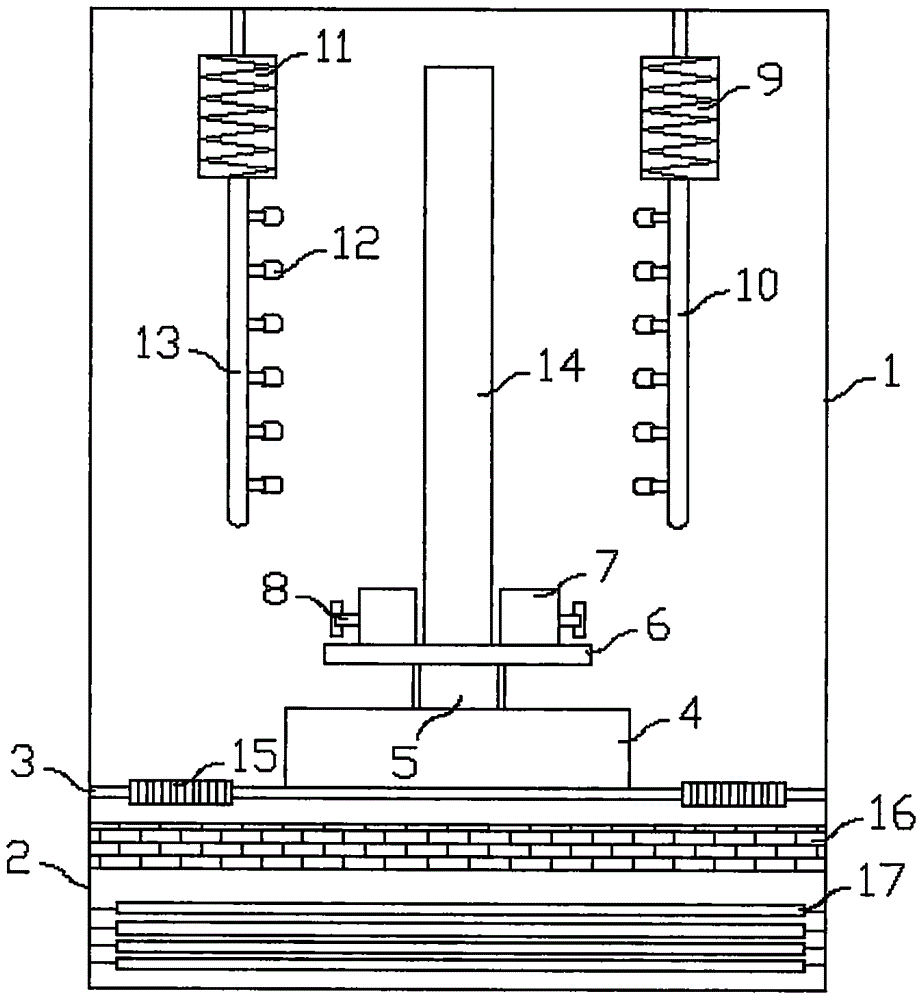

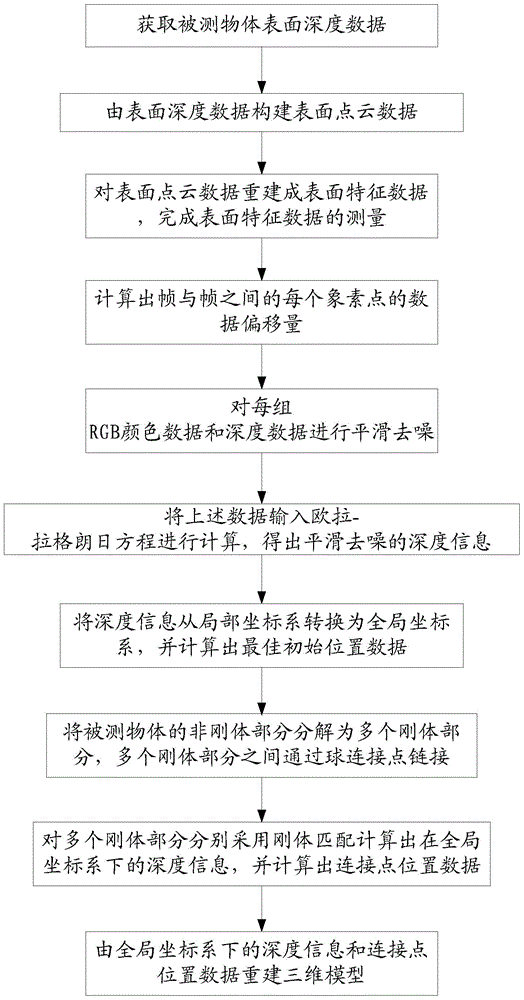

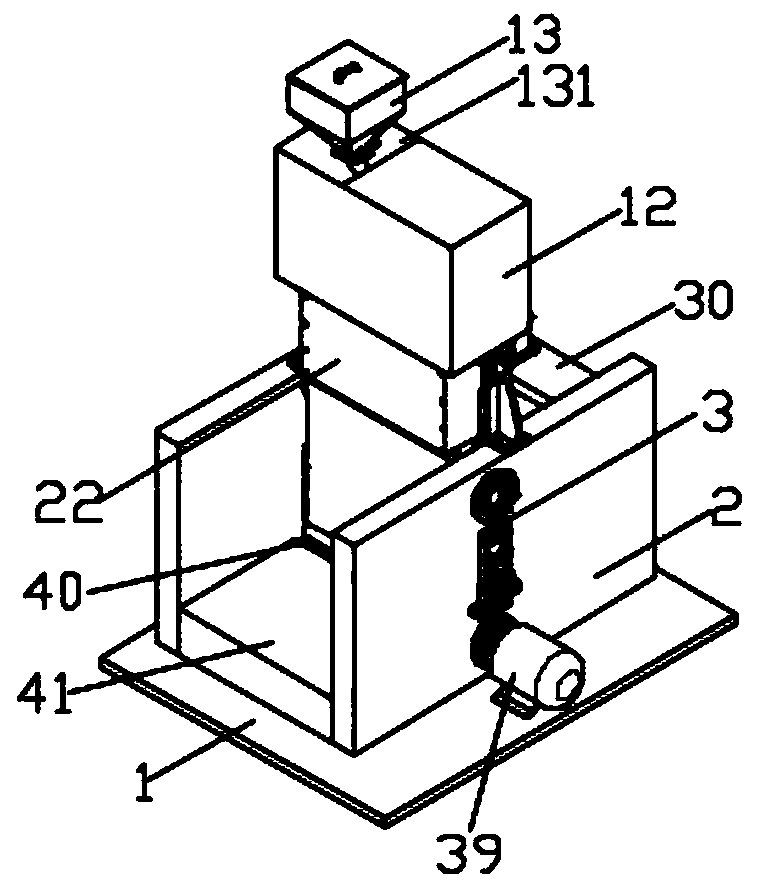

A kind of digital human body three-dimensional reconstruction method and system based on Kinect equipment

ActiveCN103955963BEffective smoothingKeep feature points3D modellingReconstruction methodDigitization

The invention relates to a digital human body three-dimensional reconstruction method based on a Kinect device. The method specifically includes the following steps that firstly, scanning is performed, and surface feature data are obtained; secondly, denoising preprocessing is performed on the surface feature data, and smooth depth information without noise is obtained; thirdly, rigid-body matching and non-rigid-body matching are sequentially performed on the depth information, and a three-dimensional model is obtained. According to the digital human body three-dimensional reconstruction method, the scanning time is short, the scanning process is simple, a hardware device needed in scanning is simple, coordination with other people or instructions learning in advance are not needed in the scanning process, the result geometric accuracy is high, the face structure, the clothes texture structure and the like are quite clear, due to a test, the system stability is high, a one-button mode is adopted in a whole system, a user does not need to set any parameter or change, a final result can be obtained as long as one button is pressed, the operation time is short, and a color map is automatically generated.

Owner:崔岩

Composite packaging material used for healthy tea sealed package

InactiveCN110683207AImprove thermoplasticityGood water solubilityFlexible coversLiquid surface applicatorsThin membraneElectric machinery

The invention discloses a composite packaging material used for healthy tea sealed package. The composite packaging material solves the technical problem that in the prior art, a composite packaging material is poor in pulling strength and heat seal strength through attaching of a heat seal layer, a first graphene layer, an aluminum foil layer, a second graphene layer, a first bonding layer, a brown paper layer, a second bonding layer, a thin film layer and a printing layer. A first motor output shaft drives a discharging screw to rotate, the discharging screw mixes a pre-mixture and extrudesthe pre-mixture out of the bottom of a discharging cylinder, the extruded pre-mixture enters an inner cavity of a coating box, a third air cylinder piston rod shrinks to drive a hydraulic rod to descend, the hydraulic rod drives the discharging cylinder to descend through a cylinder sleeve, the discharging cylinder drives a down pressing plate to descend, the down pressing plate extrudes the pre-mixture in the coating box downwards to the surface of a coating roller, a third motor output shaft drives a supporting roller to rotate, the supporting roller drives a first transmission roller and asecond transmission roller to rotate through a coating belt, and in the rotating process of the coating roller, a uniform spreading belt uniformly spreads the pre-mixture on the surface of the coatingroller.

Owner:安徽花山街网络科技有限公司

A pupil center localization method based on star rays

ActiveCN111369496BPrecise positioningEasy to detectImage enhancementImage analysisImaging processingOphthalmology

The invention belongs to the technical field of image processing, and in particular relates to a pupil center positioning method based on star rays. The invention firstly preprocesses the picture, and then uses the star ray algorithm to detect the pupil area, obtains the binarized threshold through the iterative method in the ROI area, optimizes the binarized pupil area, and eliminates the star ray edge point error. The invention can accurately detect the pupil center point under the occlusion condition. The present invention better meets the requirements of real-time performance and robustness.

Owner:ZHONGBEI UNIV

A kind of construction method of pipeline piercing pool

The invention discloses a construction method for penetrating a pool by a pipeline. The construction method comprises the following steps: 1, after binding reinforcing steel bars on the pool walls of the pool, carrying out pay-off positioning on the pool wall for the reserved pipeline and embedding the pipeline in the middle of the pool wall along the vertical direction; 2, reinforcing an embedded steel plate and the reinforcing steel bars in the pool walls; 3, setting up cylindrical wood models on both sides of the pool wall with the embedded steel plate; 4, carrying out concrete pouring on the pool wall with the models set up, and reinforcing the pool wall with the embedded steel plate; 5, after the concrete on the pool wall is air dried, dismounting the wood models; 6, cutting a circular hole in the embedded steel plate; 7, enabling the pipeline to penetrate through the circular hole of the embedded steel plate and carrying out sealing treatment; and 8, reinforcing the embedded steel plate sleeved with the pipeline and the pool walls. By using the construction method disclosed in the invention, the technical problem that the water leaks from the pool wall through the gap of the pipeline in the prior art is effectively prevented, and the technical problem that the wall surface penetrated by the pipeline is bad in appearance is solved at the same time.

Owner:TIANJIN 20 CONSTR

An automatic and precise processing system for galvanized steel sheet

ActiveCN108950448BRealize the function of automatic and precise processingNo manual operationHot-dipping/immersion processesMachining systemMechanical engineering

The invention relates to an automatic accurate processing system for a galvanized steel plate. The automatic accurate processing system comprises a galvanizing work box, the upper end face of the galvanizing work box is of a detachable structure, working grooves are formed in the front side and the rear side of the galvanizing work box, two working auxiliary rollers are arranged in each working groove through a bearing, the two working auxiliary rollers play a role in guiding and assisting movement of the steel plate when the steel plate penetrates through the galvanizing work box, a coating device is arranged on the inner wall of the upper end of the galvanizing work box and a painting device is arranged at the lower end of the galvanizing work box. According to the automatic accurate processing system, the problems that thickness of galvanizing on the surface of the steel plate cannot be effectively controlled when the existing galvanized steel plate is subjected to a galvanization processing procedure, a galvanized layer on the surface of the steel plate is not uniform, repeated detection and processing are required, the galvanized layer on the surface of the steel plate needs secondary treatment, labor intensity is high, and accuracy and working efficiency are low are solved, and intelligent high-precision galvanizing operation of the galvanized steel plate is realized.

Owner:HEFEI ORIENT METALLURGICAL EQUIP

Triangle Bezier curved surface-based method for fairing STL model of products

Owner:SHANDONG UNIV OF TECH

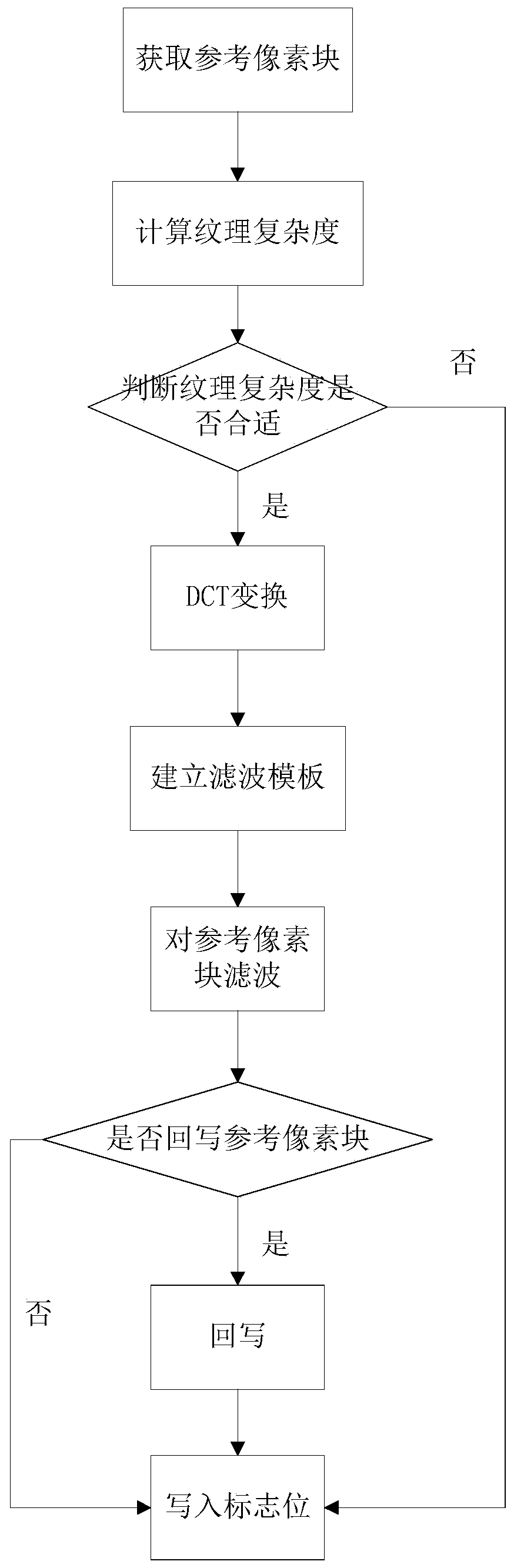

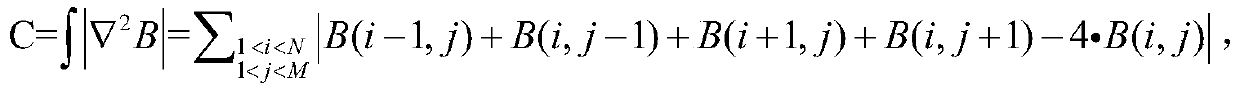

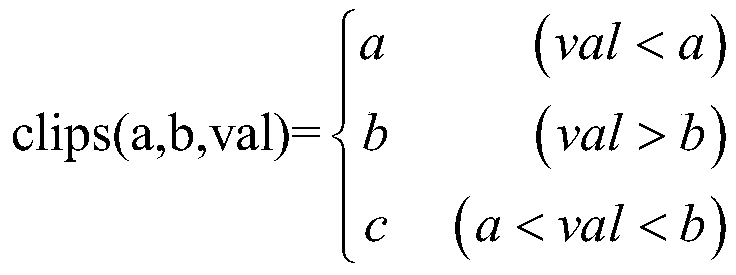

Video Coding Reference Block Filtering Method

ActiveCN107295353BEffective smoothingAvoid filteringDigital video signal modificationPattern recognitionVideo encoding

The present invention relates to a video coding reference block filtering method, comprising: A. calculating the current reference pixel block B. ref The texture complexity C; B. Reference pixel block B ref DCT transformation to obtain the transformation coefficient matrix I ref , calculate B ref The horizontal and vertical frequency distribution strength of the horizontal and vertical frequency distribution, and the corresponding horizontal and vertical filter factors; C. Establish and reference pixel block B ref The filter template U of the same size; D. The transformation coefficient matrix I will be obtained ref Multiply with the matrix of the filter template U to obtain the filtered coefficient matrix, and perform IDCT transformation to obtain the filtered reference pixel block; E. According to whether the average absolute difference and complexity of the filtered reference pixel block are reduced, determine whether to filter the filtered reference pixel block Write back reference pixel block to reference pixel block B ref middle. The present invention can effectively smooth the image texture, significantly improve the performance of image coding, and also avoid filtering the pixel blocks with good quality and reference, and realize the purpose of self-adaptively improving the quality of reference images .

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

A kind of surface treatment process of galvanized steel sheet

ActiveCN108796420BControl thicknessHigh precisionHot-dipping/immersion processesMachiningSecondary treatment

The invention relates to a galvanized steel sheet surface treatment process. The galvanized steel sheet surface treatment process comprises the following specific steps of (1) steel sheet uncoiling, wherein a steel sheet is driven to move at constant speed; (2) acid pickling treatment; (3) drying treatment; (4) steel sheet heating; (5) galvanizing machining, wherein the dried steel sheet is subjected to galvanizing machining work through a galvanizing work box under the action of uncoiling equipment, work troughs are arranged on the front side and the rear side of the galvanizing work box, a coating device is arranged on the inner wall of the upper end of the galvanizing work box, and a smearing device is arranged at the lower end of the galvanizing work box; and (6) galvanizing aftertreatment. According to the galvanized steel sheet surface treatment process, the problems that the thickness of steel sheet surface galvanizing cannot be effectively controlled during the galvanizing machining procedures of an existing galvanized steel sheet, the galvanized layer on the surface of the steel sheet is uneven, multiple times of detecting and machining are needed, the galvanized layer onthe surface of the steel sheet needs to be subjected to secondary treatment, the labor intensity is large, the precision is poor, and the work efficiency is low are solved, and the intelligent high-precision galvanizing work function of the galvanized steel sheet can be achieved.

Owner:重庆中会表面处理有限公司

An automatic production line for synthesis of imitation granite marble coating

ActiveCN109046883BControl UniformityRealize the function of automatic processingLiquid surface applicatorsCoatingsAir velocityProcess engineering

The invention mainly relates to an automatic production line for granite-like marble paint synthesis. The automatic production line comprises a base plate; a support working frame is mounted on the base plate; an adjustment spraying device is mounted between the inner walls of the support working frame; an auxiliary lifting device is mounted on the support working frame, and is connected with a driving device; and the driving device is mounted on the base plate. The automatic production line can solve the difficulties of need of manually controlling a spraying machine to spray raw materials manufactured by artificial-synthesized rock slices in the production process of traditional granite-like marble paint, need of manually controlling the spraying thickness of the raw materials, incapability of guaranteeing the spraying thickness of the raw materials due to manual control of the spraying machine, incapability of guaranteeing the spraying uniformity, long natural airing time of the rawmaterials after spraying, higher influence on the surfaces of the sprayed raw materials by the air speed generated by manual use of drying equipment, need of manually conveying the dried raw materials, high labor intensity and low working efficiency.

Owner:宁波富丽佳涂料有限公司

Cloth processing device for garment processing

A cloth processing device for garment processing, comprising a bottom plate, cloth rollers in the front and rear directions are installed on the left side of the top surface of the bottom plate through a first bracket, cloth is wound around the outer periphery of the cloth rollers, and a device for driving the cloth rollers to rotate is provided on the front side of the first bracket. The first power device, the second bracket is fixedly installed in the middle part of the top surface of the bottom plate, the first rotating shaft in the front and rear direction is installed in the front middle part of the second bracket, the second bracket is also provided with a second power device that drives the first rotating shaft to rotate, the first rotating shaft The outer circumference of the front side of the front side is annular and equidistantly installed with three first sleeve pipes with open outer ends. The present invention adopts the way that the first motor drives the second tube to rotate—fixing needle as a fixing device makes the cloth wrap around the outer circumference of the roller core, so that the first sleeve located at the lower part of the first rotating shaft is in a vertical state, and the lowermost roller core makes the cloth Located between the roller core and the top surface of the bottom plate, it can effectively smooth the fabric, prevent folding and unevenness during the winding process, and can also control the length of the fabric, and can roll the fabric as needed.

Owner:重庆恒升服饰制造有限公司

Concrete pavement leveling device for highway construction

ActiveCN113322765AEasy to handleImprove the leveling effectRoads maintainenceClassical mechanicsStructural engineering

The invention relates to a concrete pavement leveling device for highway construction, and belongs to the technical field of pavement construction. The concrete pavement leveling device comprises a first ring disc, a second ring disc and a middle shell; the circumferential inner wall of the first ring disc is rotatably connected with the circumferential outer wall of the middle shell; the second ring disc is rotatably connected to the circumferential outer wall of the second ring disc; a rotating assembly enabling the second ring disc and the first ring disc to rotate reversely together is arranged between the second ring disc and the first ring disc; a plurality of guide grooves are formed in the inner bottom wall of the second ring disc; the lower surface of the first ring disc abuts against the ground; and the guide grooves are spirally converged towards the center of the second ring disc in the direction opposite to the second ring disc. The concrete pavement leveling device can improve the concrete pavement leveling operation quality.

Owner:中能建路桥工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com