A fabric anti-wrinkle winding device

A coiling device and cloth technology, applied in the direction of winding strips, thin material processing, transportation and packaging, etc., can solve the problems of uneven dyeing, affecting the quality of gray cloth, and the difference in tension between double-width gray cloth, so as to increase the left and right stretching force, The effect of improving coiling efficiency and ensuring the quality of gray cloth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

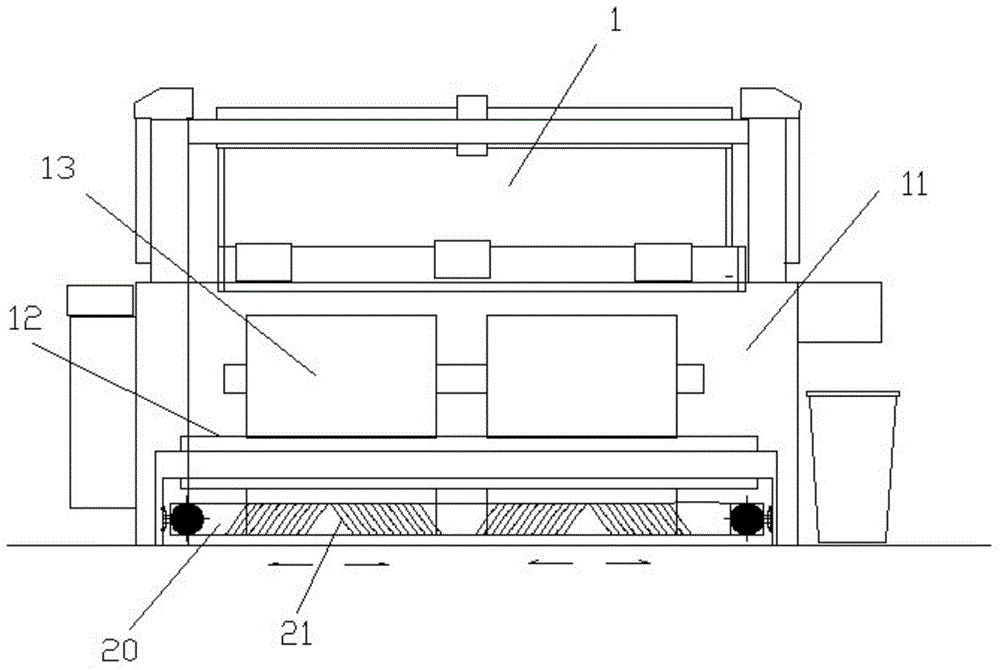

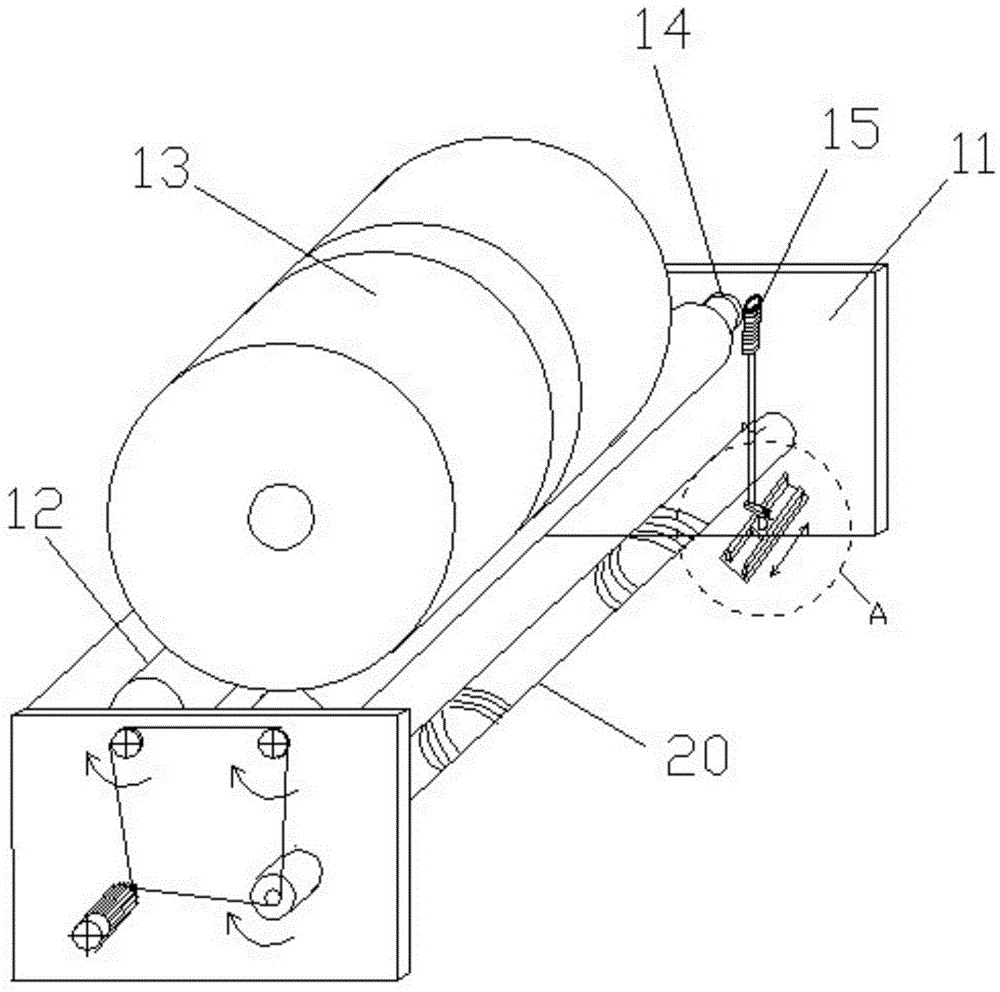

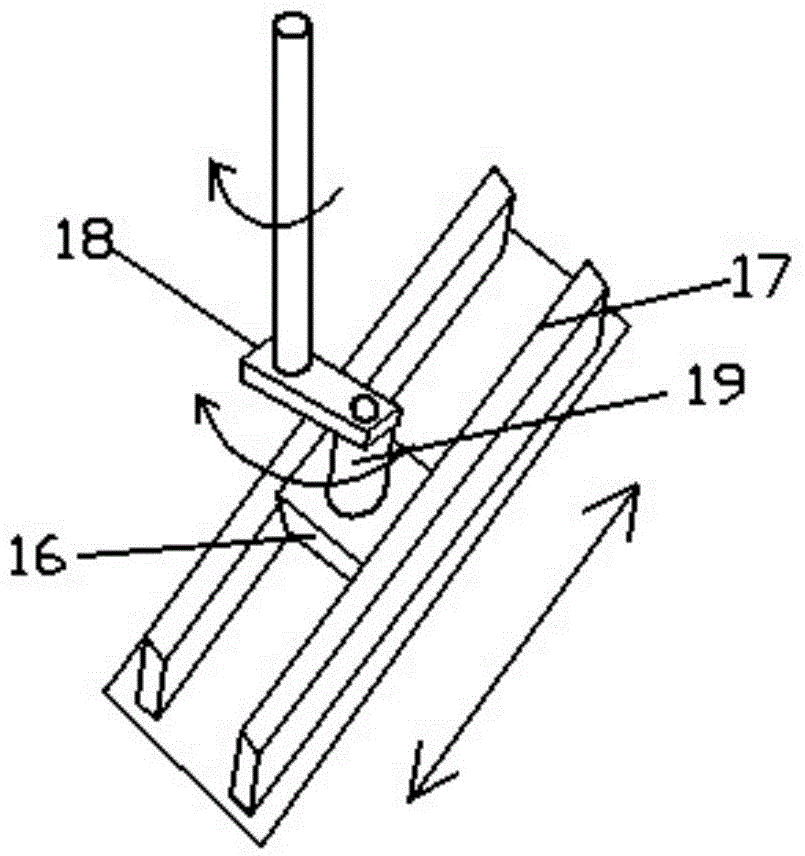

[0025] When the gray cloth is finished weaving, its edge is rough, which needs to be folded in to form a smooth edge. The thickness of the folded side track is twice that of the rough edge. When the thickness is stacked, the side track is high and the inner width is low. As a result, the phenomenon of slack in the inner panel is caused, and wrinkles will occur when the gray cloth is wound at a slow speed. And at present, the new product development is carried out on the knee double-width lining. Due to the difference in tension between the double-width gray cloth, it is very easy to wrinkle when the double-width knee silk is wound, and the gray cloth cannot be produced normally, which seriously affects the quality of the gray cloth and the subsequent dyeing process. decline.

[0026] Aiming at the deficiencies in the prior art, the present invention provides a fabric anti-wrinkle coiling device, which drives the frame and guide rollers to run, and adds anti-wrinkle guide rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com