Local heating device

A technology of local heating and heating part, which is applied in the direction of lamination device, lamination auxiliary operation, lamination, etc. It can solve problems such as failure to level off, product quality problems, and material curling, so as to protect safety and reduce damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

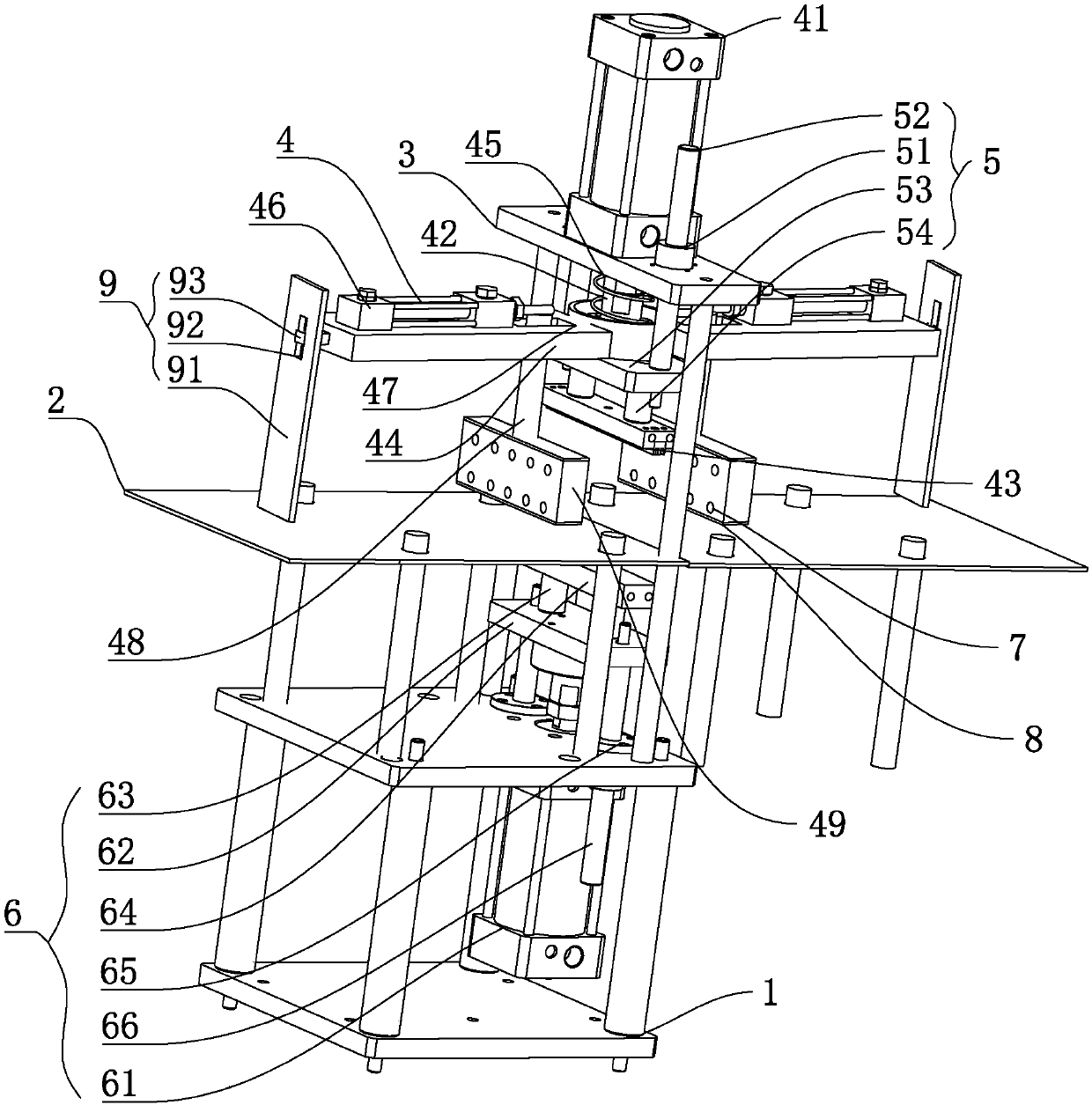

[0023] Embodiment 1: a kind of local heating device, such as figure 1 As shown, it includes a frame 1 and an operating platform 2 positioned on the frame 1. The frame 1 is provided with a support frame 3, and the support frame 3 is provided with a first heating part 4. The first heating part 4 includes a The first cylinder 41 provided on the top, the outlet of the first cylinder 41 is provided with a vertically downward telescopic rod 42, the telescopic rod 42 runs through the support frame 3, and guide devices 5 are also provided on both sides of the first cylinder 41, and the guide device 5 includes The first linear bearing 51 located on both sides of the first cylinder 41 is provided with a first guide shaft 52 that matches the first linear bearing 51 and runs through the support frame 3 on the first linear bearing 51 , and on the telescopic rod 42 The top end is fixedly connected with a first heating fixed plate 53, and at the same time, both sides of the first heating fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com