A kind of surface treatment process of galvanized steel sheet

A surface treatment, galvanized steel sheet technology, applied in hot dip plating process, metal material coating process, coating and other directions, can solve the problems of high work efficiency, poor accuracy, low labor intensity, etc., to achieve high work efficiency, Ensure flatness and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

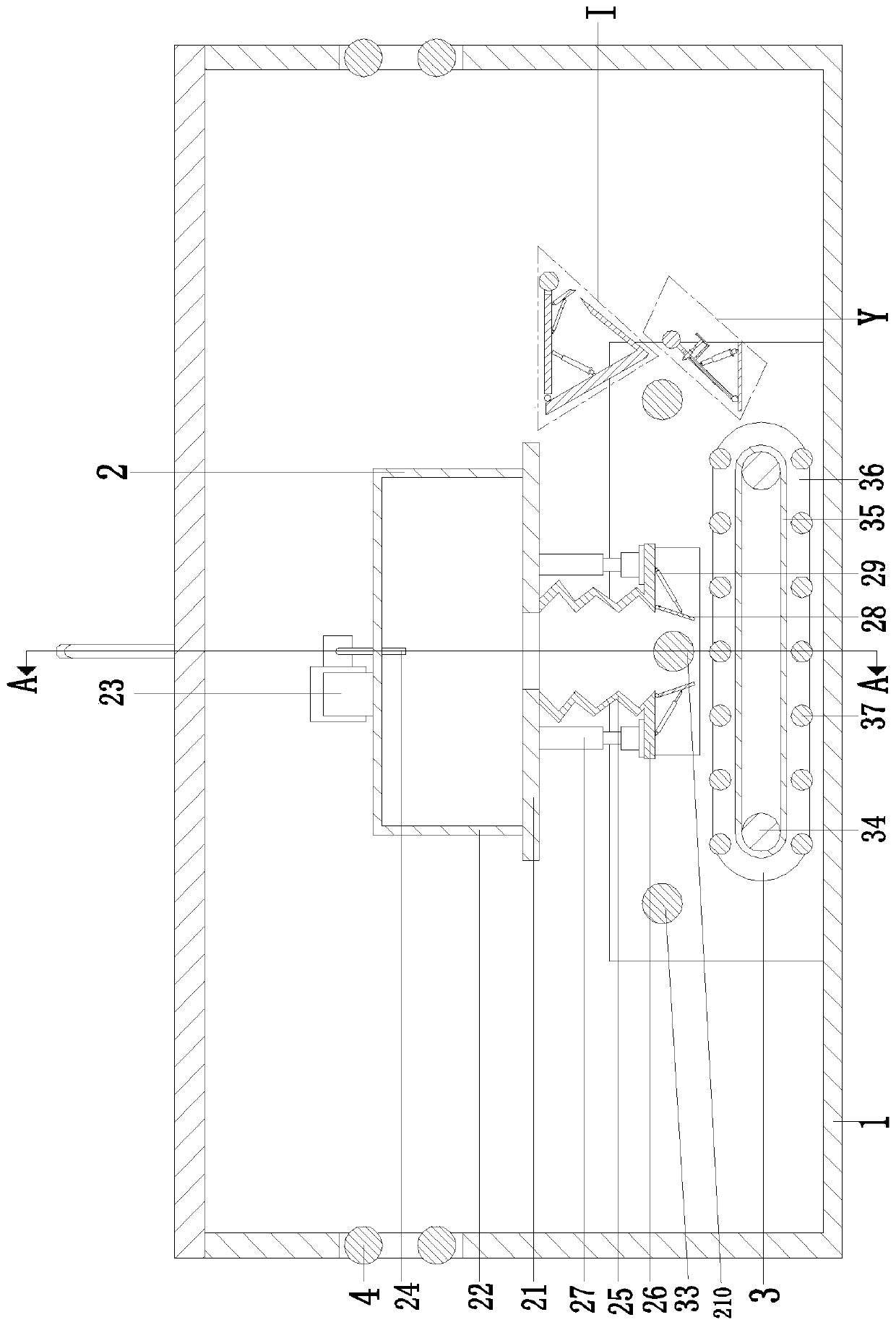

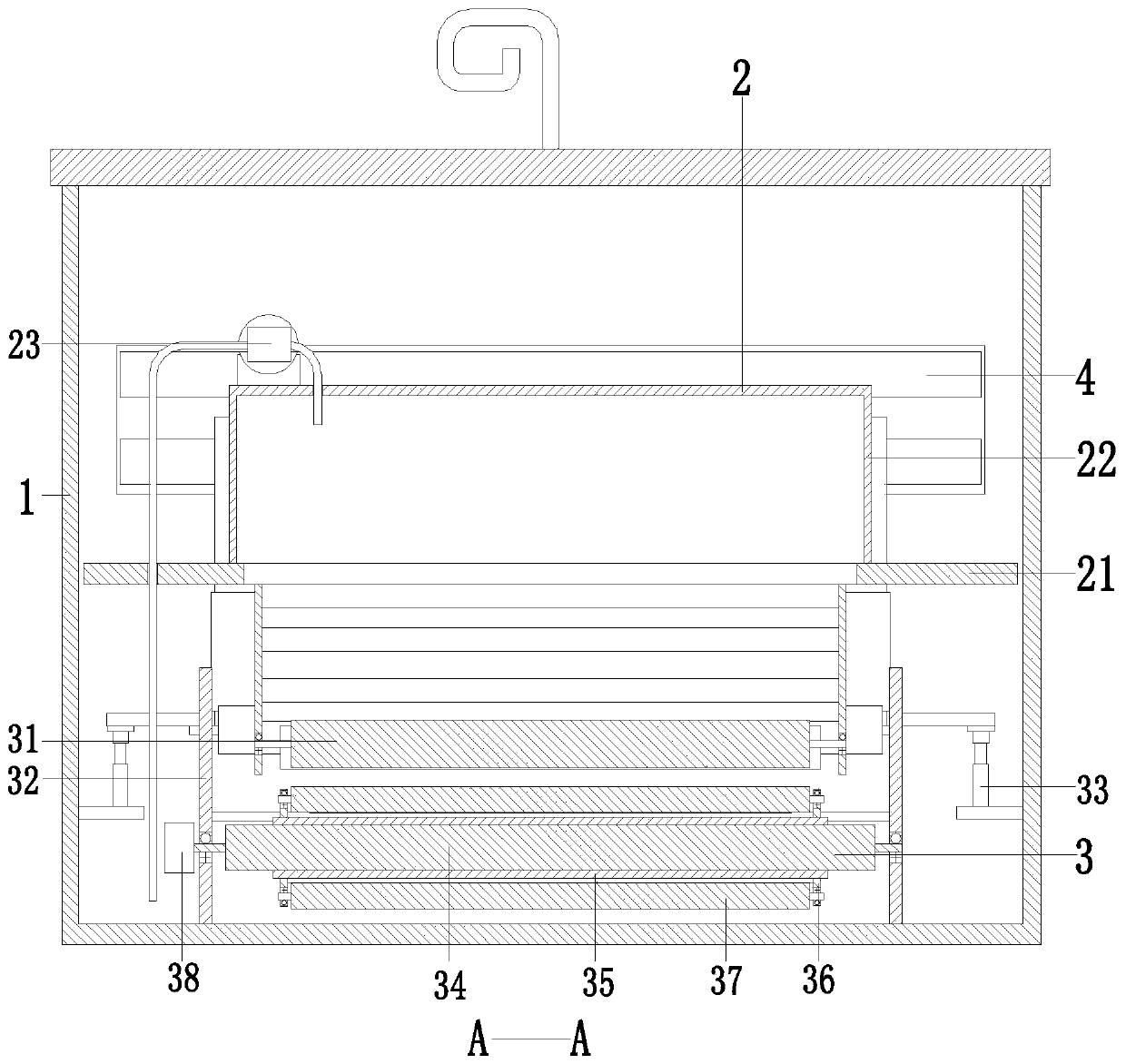

[0026] In order to make it easy to understand the technical means, creative features, objectives and effects achieved by the present invention, the present invention will be further explained below in conjunction with specific drawings.

[0027] Such as Figure 1 to Figure 5 As shown, a galvanized steel sheet surface treatment process includes the following steps:

[0028] Step 1: Uncoiling the steel plate, place the coiled steel plate on the decoiler, and the decoiler uncoils the steel coil at a speed of 2m / min;

[0029] Step 2. Pickling treatment. Use a pickling solution to clean the surface of the annealed steel plate. The pickling solution is a hydrochloric acid solution with a concentration of 50% to 53%. During cleaning, all the steel plates are immersed in the solution and soaked in pickling The time is 15-20min, and the pickling temperature is 60-65℃;

[0030] Step three, drying treatment, the steel plate after pickling treatment is placed in an oven, the temperature in the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com