Two-line progressive distributor

A distributor and control chip technology, applied in the field of lubrication, can solve the problems of complex system configuration, inconvenient installation, complex structure, etc., and achieve the effect of simple system configuration, reasonable structure setting and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

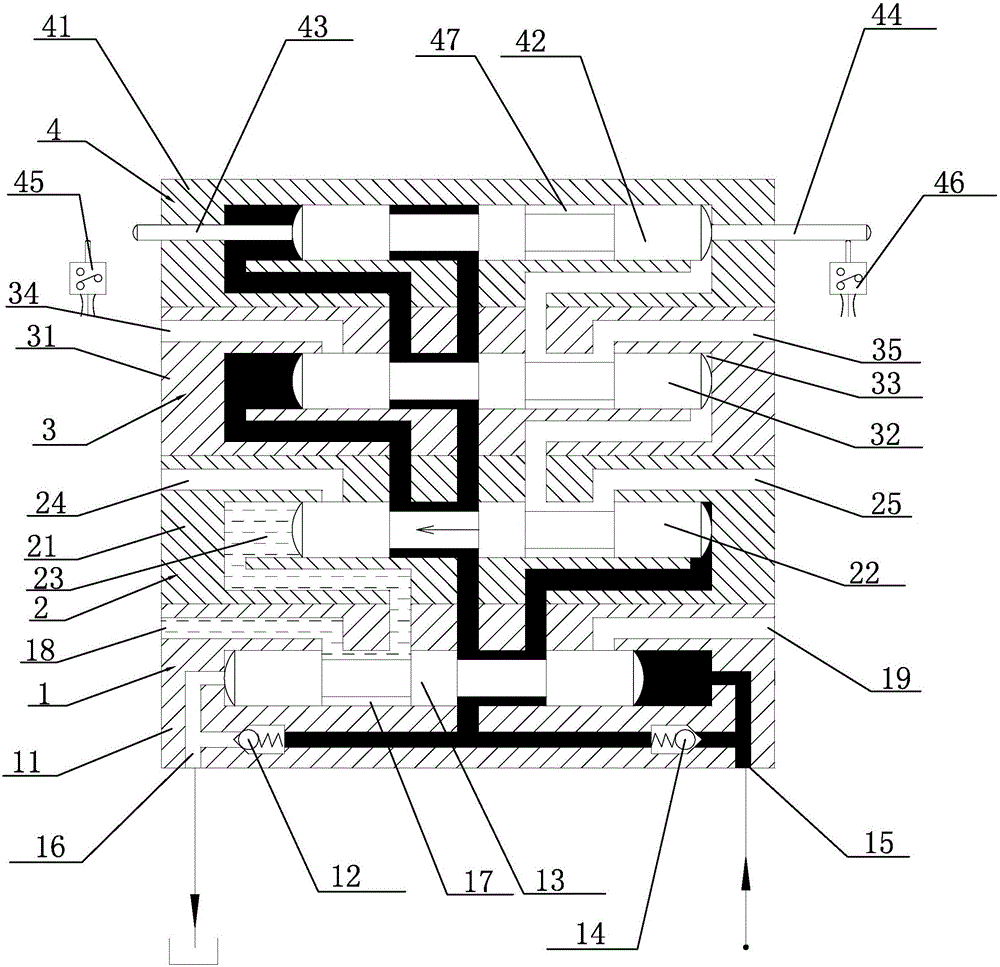

[0026] see Figure 1 to Figure 8 , a double-line progressive dispenser disclosed by the present invention, comprising a control sheet 1, a first metering sheet 2, a second metering sheet 3 and a third metering sheet 4, the control sheet 1, the first metering sheet 2, the second metering sheet The second metering sheet 3 and the third metering sheet 4 are stacked sequentially from bottom to top. The control sheet 1 includes a control sheet body 11, a first one-way valve 12, a control plunger 13 and a second one-way valve 14. The first metering sheet 2 includes a first metering sheet body 21 and a first metering plunger 22, the second metering sheet 3 includes a second metering sheet body 31 and a second metering plunger 32, and the third metering sheet 4 includes a first metering sheet body 21 and a first metering plunger 22. Three metering sheet bodies 41, the third metering plunger 42, the first action indicator rod 43, the second action indicator rod 44, the first signaling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com