Automatic crude oil water content measuring instrument

A fully automatic technology for measuring the water content of crude oil, applied in instruments, measuring devices, scientific instruments, etc., can solve problems such as oil temperature rise, oil droplets splashing into it, deflagration and fire, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

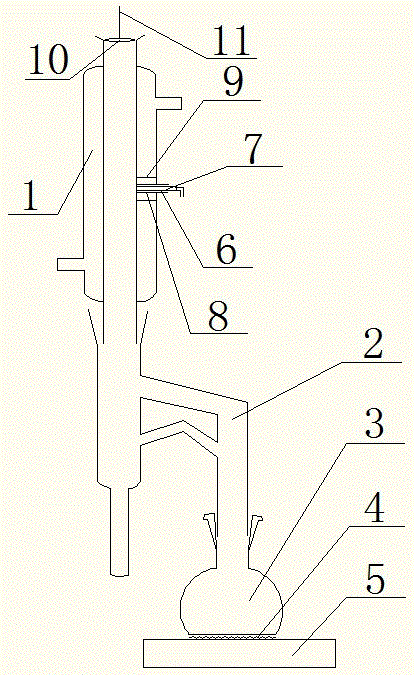

[0021] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a condenser tube 1, a receiver 2 is arranged under the condenser tube 1, a flask 3 is arranged under the receiver 2, a magnetic conduction layer 4 is sintered on the bottom of the flask 3, and the flask 3 is placed on a high-frequency electromagnetic heater 5. A temperature measuring port 6 is opened on the side of the condenser tube 1 , and a temperature sensor 7 is inserted in the temperature measuring port 6 . An outer isolation ring 8 is arranged on the periphery of the temperature sensor 7, an inner isolation ring 9 is arranged on the outer periphery of the outer isolation ring 8, and a vacuum is drawn between the outer isolation ring 8 and the inner isolation ring 9. An automatic poking head 10 is provided on the top of the condenser tube 1 . The automatic poking head 10 is connected with an operating rod 11 . The bottom of the flask 3 is a plane or a spheric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com