Method and device for predicting oil temperature of transformer top layer based on error prediction and correction

A technology for top-level oil temperature and error prediction, applied in the fields of instrument, character and pattern recognition, calculation, etc., can solve the problems of oversimplification of the model, general pertinence, and unresearched generality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

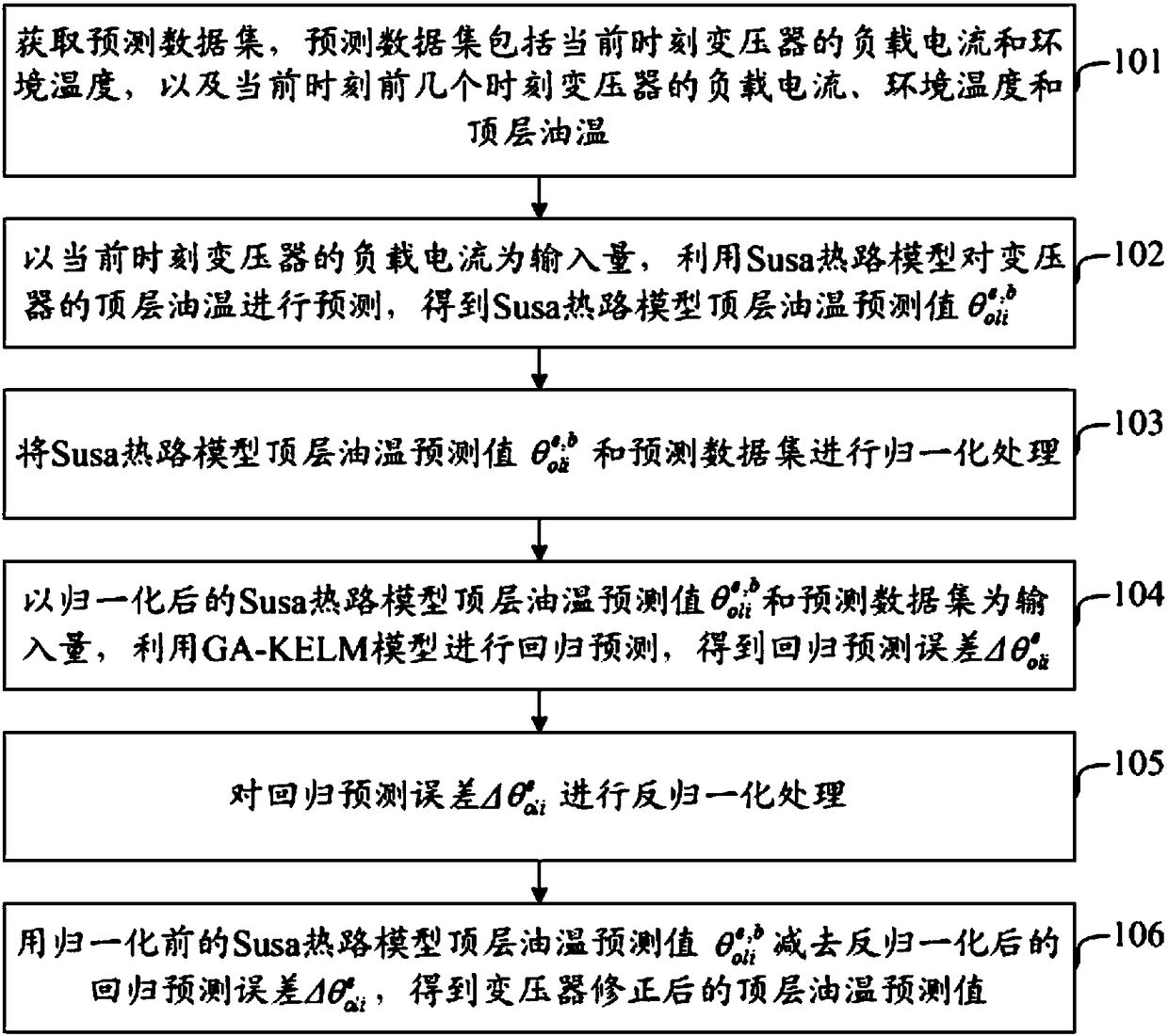

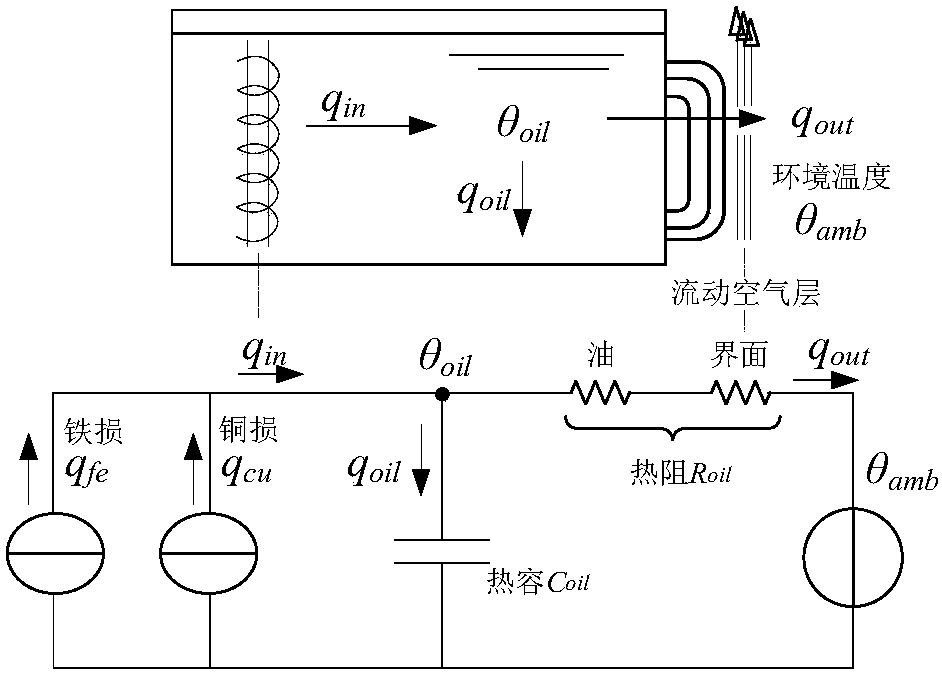

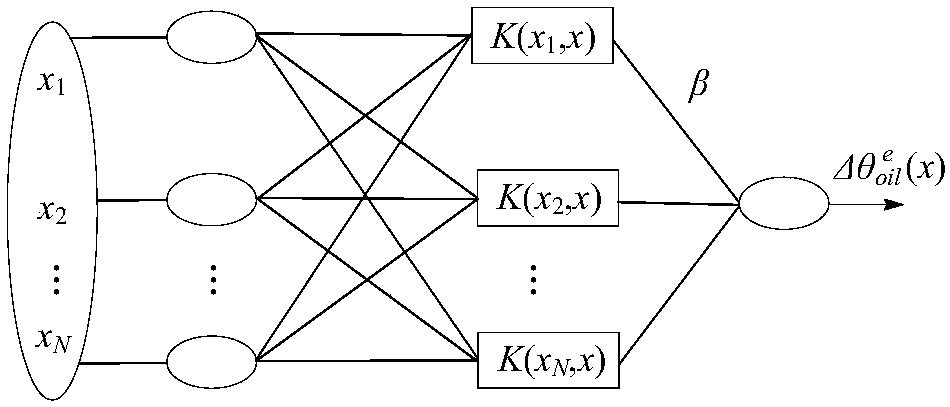

[0082] On the one hand, the present invention provides a method for predicting oil temperature at the top of a transformer based on error prediction correction, such as figure 1 and Figure 4 shown, including:

[0083] Step 101: Obtain a forecast data set, which includes the load current and ambient temperature of the transformer at the current moment, and the load current, ambient temperature, and top oil temperature of the transformer at several moments before the current moment.

[0084] The oil temperature at the top of the transformer is closely related to the load current and ambient temperature of the transformer, and the oil temperature at the top will also be affected by the load current, ambient temperature, and oil temperature of the transfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com