Permanent magnet synchronous motor rotor used for driving new energy automobile

A technology for permanent magnet synchronous motors and new energy vehicles. It is applied to synchronous motors with stationary armatures and rotating magnets, synchronous machines, and magnetic circuits. It can solve unfavorable motor structure optimization and production processing, and does not involve matching of large and small slots. Design, complex structure of the motor, etc., to improve starting performance and working characteristics, increase effective use area, and save space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

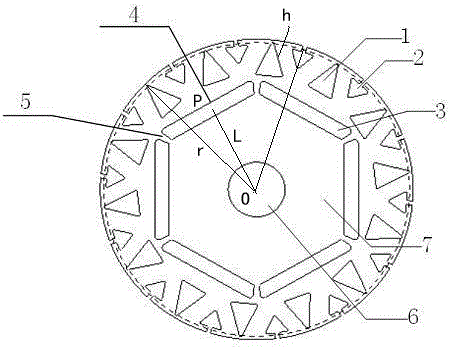

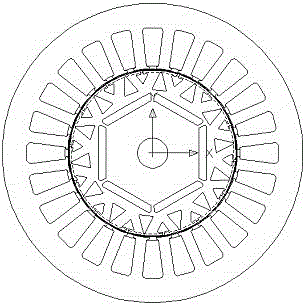

[0013] Such as figure 1 , figure 2 As shown, the present invention is a permanent magnet synchronous motor rotor for driving a new energy vehicle, comprising a permanent magnet magnetic steel 3, a permanent magnet magnetic steel groove 4, a magnetic isolation bridge 5, a central shaft 6 and a rotor core 7, and the permanent magnet The magnetic steel 3 is placed in the permanent magnet magnetic steel groove 4, and the permanent magnet magnetic steel groove 4 is in the shape of a line, forming a V-shaped magnetic steel with 2 poles of the rotor; a magnetic isolation magnetic bridge 5 is arranged between the permanent magnet magnetic steel 3, and the large groove 1 is a closed triangular slot, and small slot 2 is an open triangular slot, both of which are isosceles triangles. The number of the two is the same, 14 to 28. The large slot 1 and the small slot 2 are arranged at intervals and evenly distributed on the circumference of the rotor; The bisector of the top angle of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com