Photovoltaic connection box and photovoltaic assembly connection system

A technology of volt junction boxes and photovoltaic modules, applied in photovoltaic power generation, photovoltaic modules, electrical components, etc., can solve problems such as cracking, high contact resistance, temperature rise, etc., to facilitate troubleshooting, easy inspection, and avoid failures. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

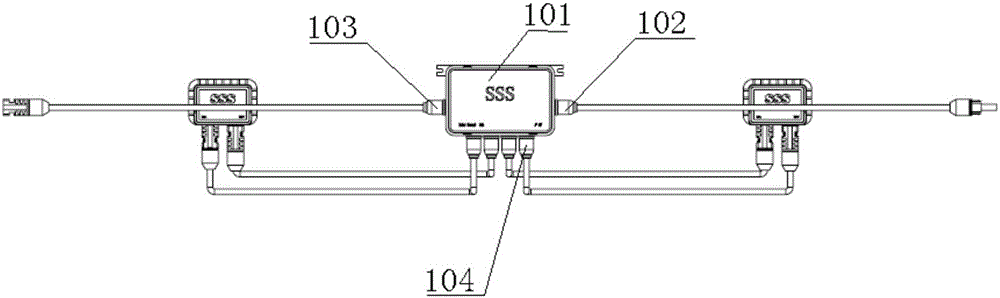

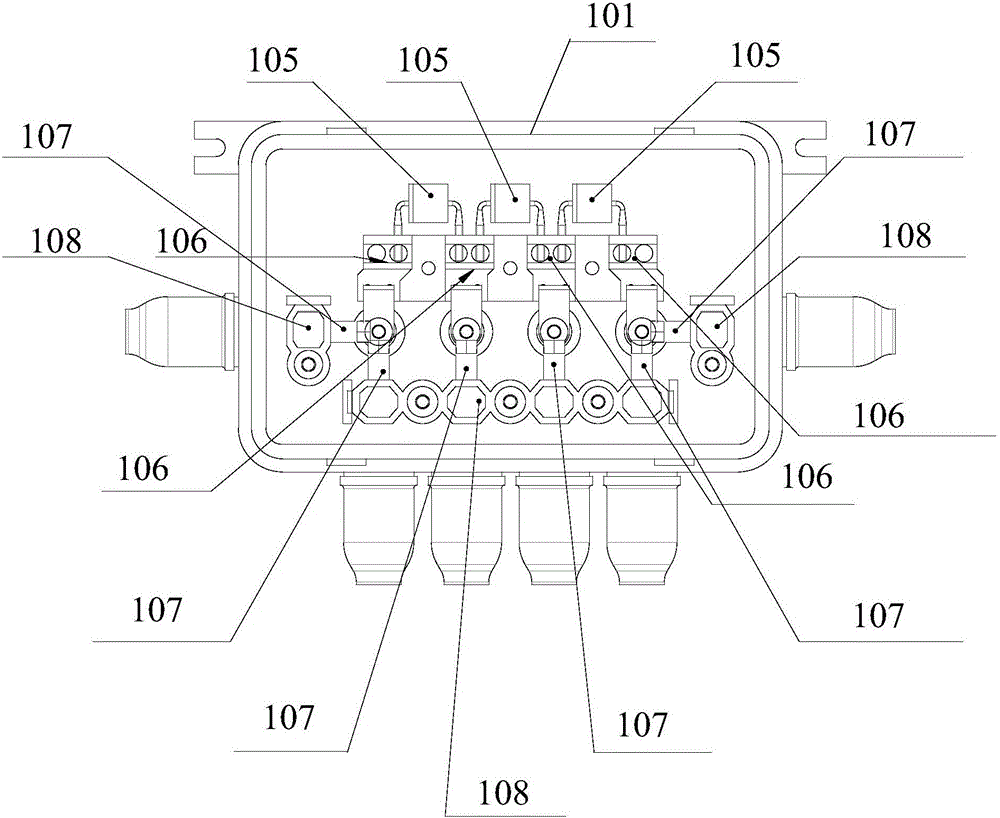

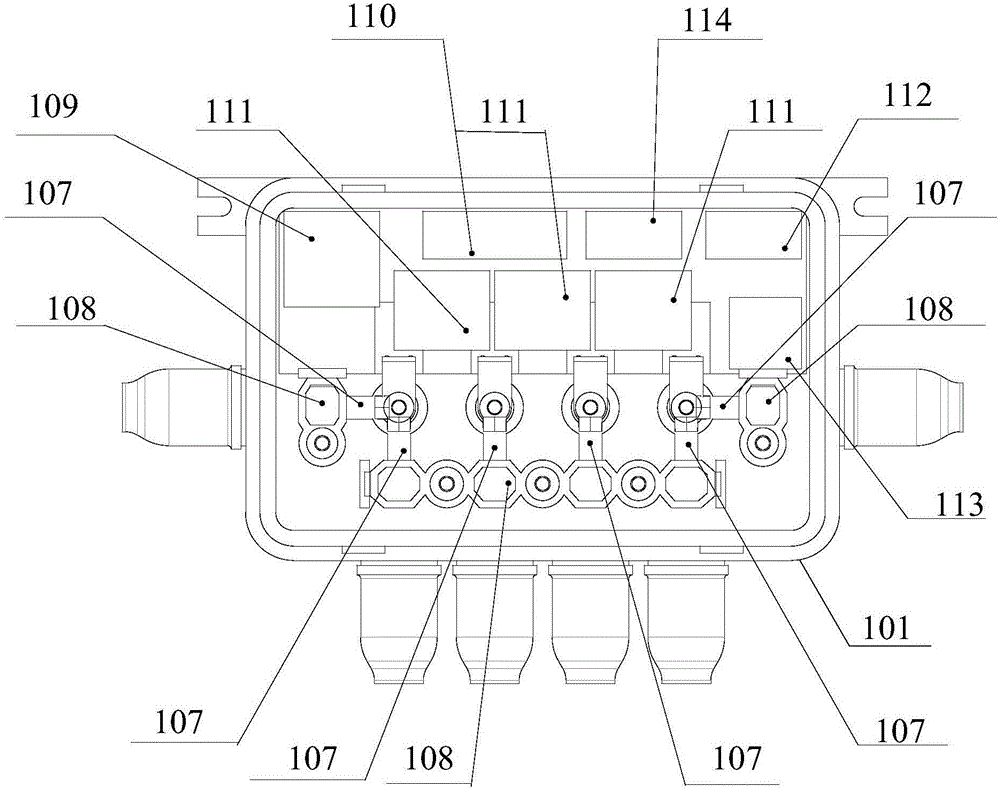

[0053] Such as figure 1 , 2 As shown, it is the photovoltaic junction box according to Embodiment 1 of the present invention, which includes a box body 101, a positive connection terminal 102, a negative connection terminal 103, four component connection terminals 104, and at least one bypass diode arranged outside the box body Module 105 or intelligent power management module;

[0054] The positive connection terminal 102 is used to connect with the positive connector through the positive wire;

[0055] The negative connection terminal 103 is used to connect with the negative connector through the negative wire;

[0056] The four component connection ends 104 communicate with the inside and outside of the juncti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com