Processing method for improving flatness of soft and hard combined plate

A technology of soft and hard combination board and processing method, which is applied in the direction of electrical components, printed circuit manufacturing, printed circuit, etc., can solve the problems of poor shooting effect and low flatness precision, and achieve the effect of improving flatness and good shooting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

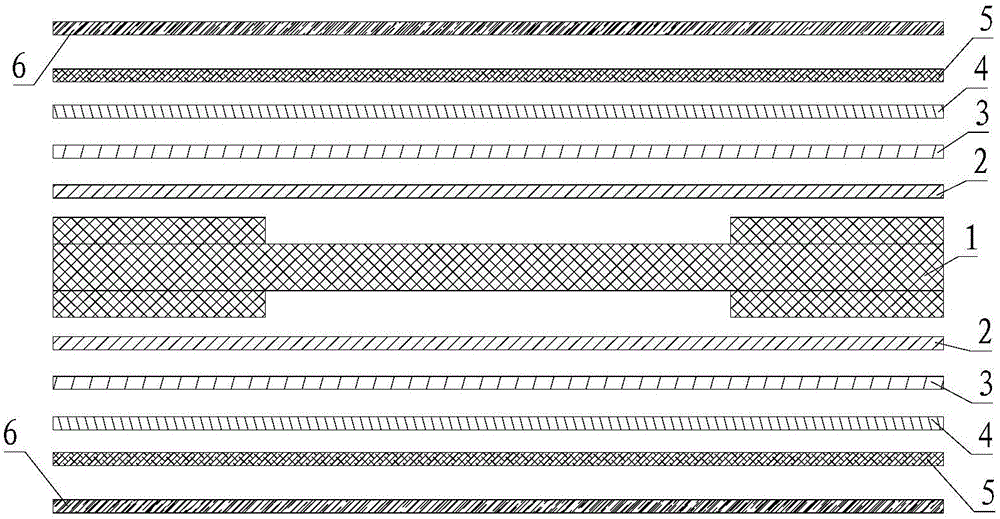

[0012] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0013] The most critical conception of the present invention is: the method of the present invention adopts the lamination of steel plate, kraft paper, PE film, aluminum sheet, separator, rigid-flex board, separator, aluminum sheet, PE film, kraft paper and steel plate from bottom to top It is a processing method that can effectively improve the flatness of rigid-flex boards.

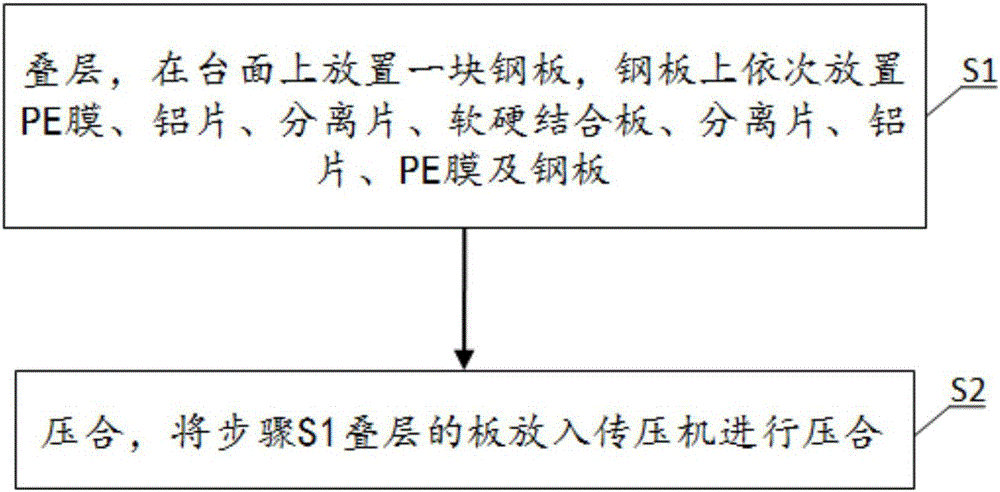

[0014] see figure 1 , the present invention improves the processing method of the flatness of the rigid-flex board,

[0015] Including the following steps,

[0016] S1, stacking, place a steel plate on the table, place PE film, aluminum sheet, separator, soft and hard combination board, separator, aluminum sheet, PE film and steel plate in sequence on the steel pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com