Sputtering target, optical functional film and laminated wiring film

A technology of optical function and sputtering target, which is applied in optics, optical components, sputtering coating, etc., can solve problems such as difficult to use touch panels, and achieve the effects of reduced masking, excellent reliability, and satisfactory reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

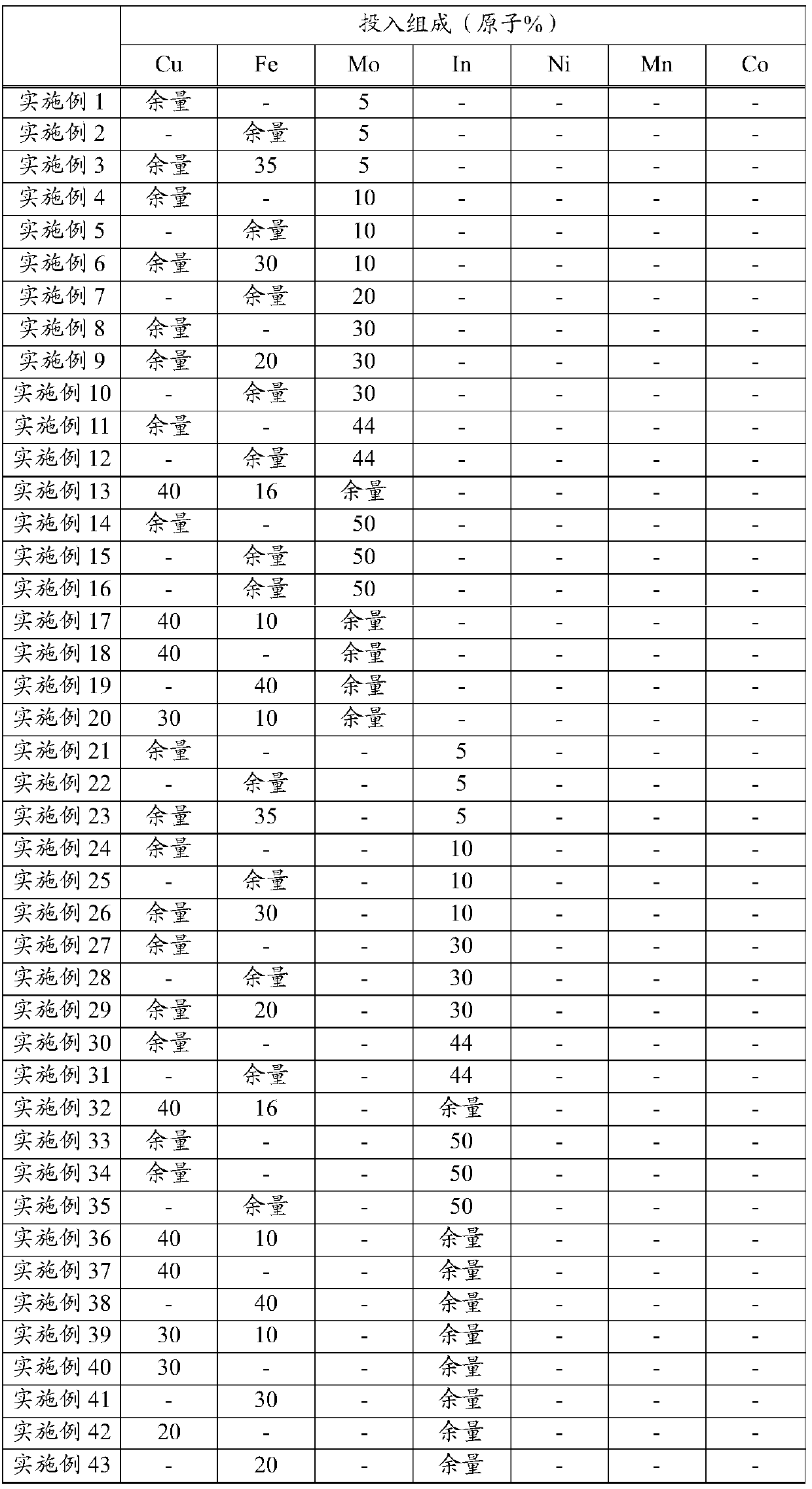

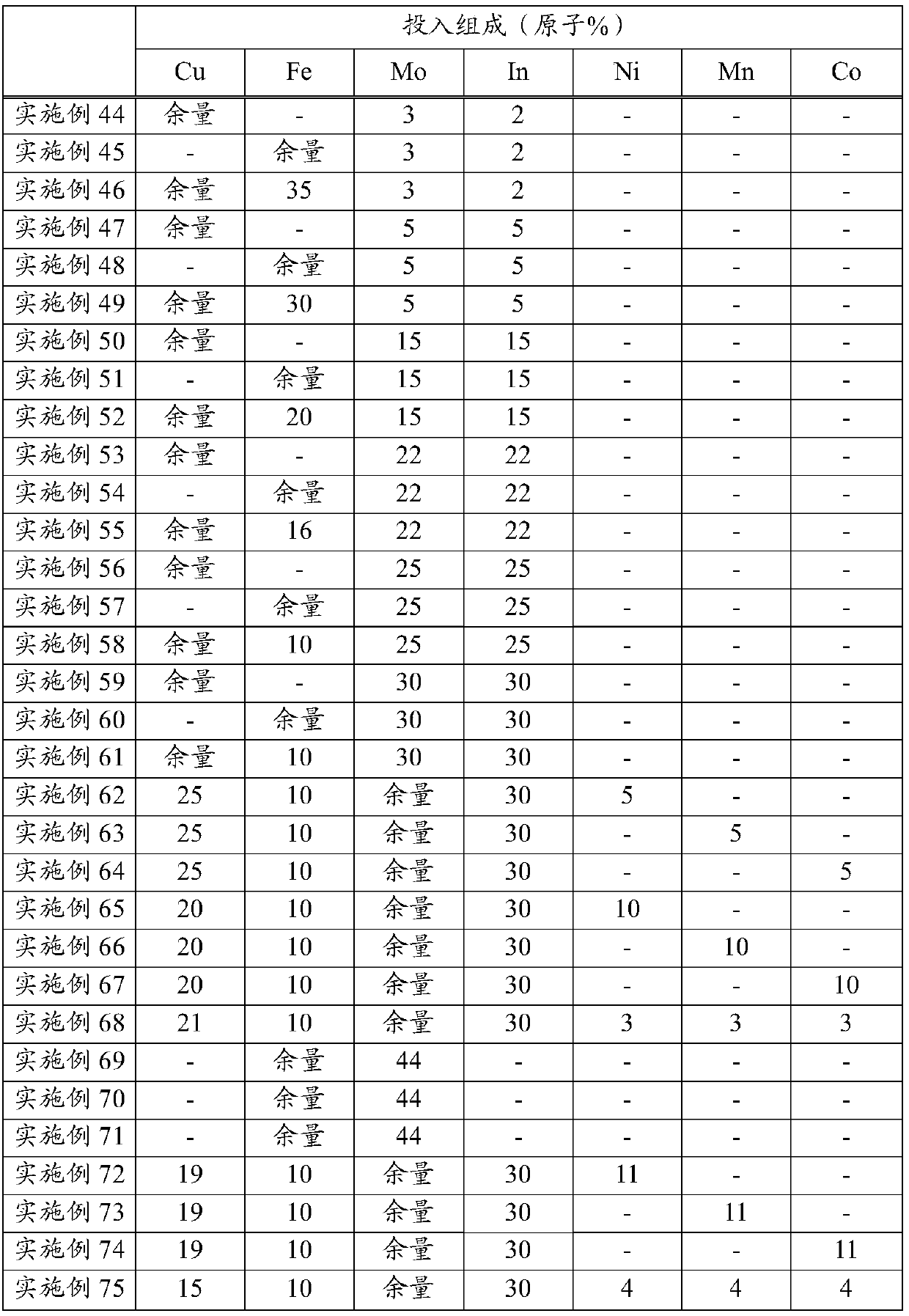

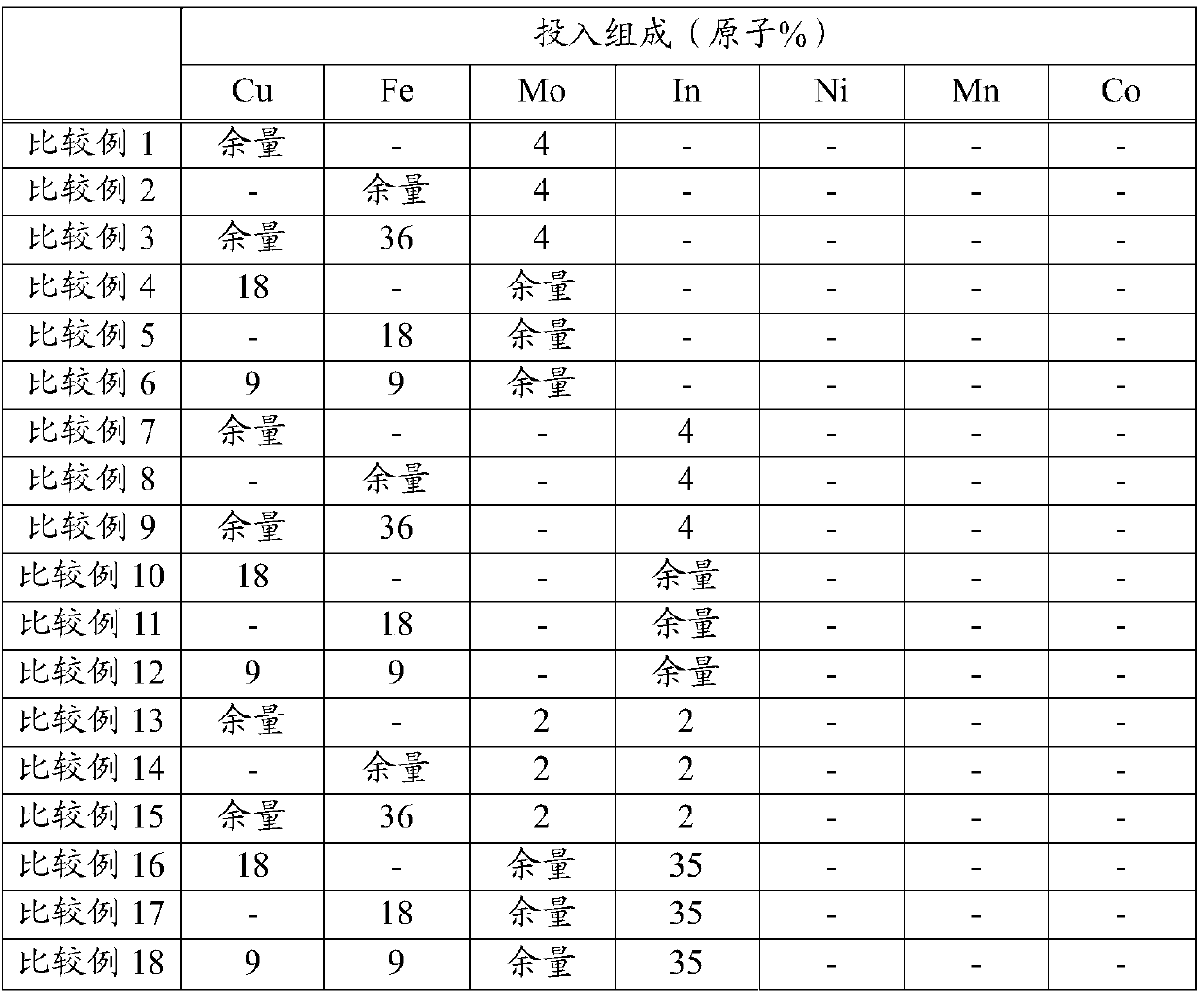

[0037] Next, the sputtering target of the present invention and an optical functional film formed using the sputtering target will be specifically described below using examples.

[0038] [Example]

[0039] First, to fabricate the sputtering target, MoO 2 Powder, In 2 o 3 powder, CuO powder, Fe 3 o 4 powder, NiO powder, Mn 2 o 3 Powder and Co 3 o 4 powder. Next, they were weighed so that the target material composition ratios (metal only) shown in Table 1 and Table 2 were obtained, and each powder weighed was filled in a mixing device and mixed to prepare Examples 1-6, 9- Mixed powders of 13, 15, 17-18, 20-26, 28-32, 35-39, 41, 43-75. Using the mixed powder of each example as a raw material, temperature: 700°C, pressure: 300kgf / cm 2 (29.4 MPa) was hot-pressed in vacuum for 3 hours to produce a sintered body. These sintered bodies were machined to a diameter of 152.4 mm and a thickness of 6 mm, and were pasted on a Cu backing plate with In solder to produce examples...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com