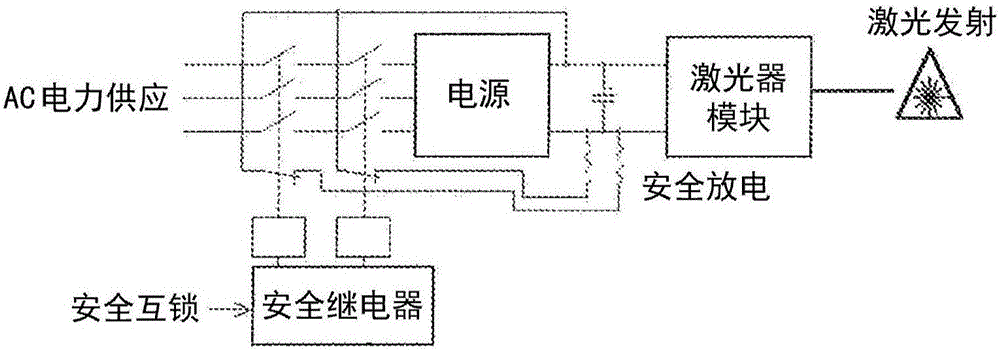

High power fiber laser safety control system

A safety control and laser technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve problems such as increasing system prices, adverse effects on brightness system reliability, and reducing radiation quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

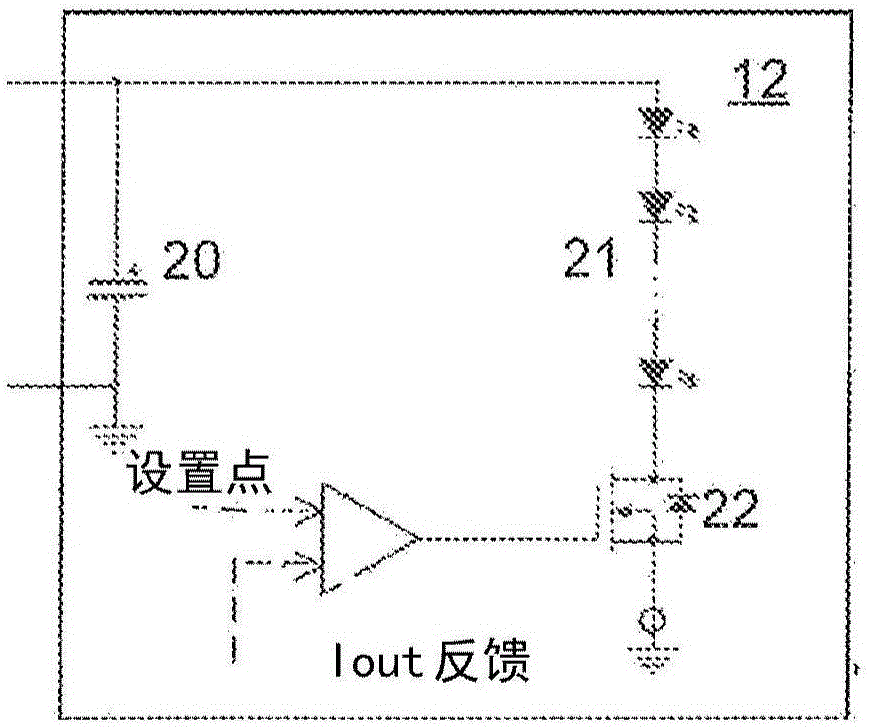

[0033] figure 2 A pumping module of a fiber laser with a linear pump current control element 22 is shown, wherein the linear pump current control element 22 is a MOSFET.

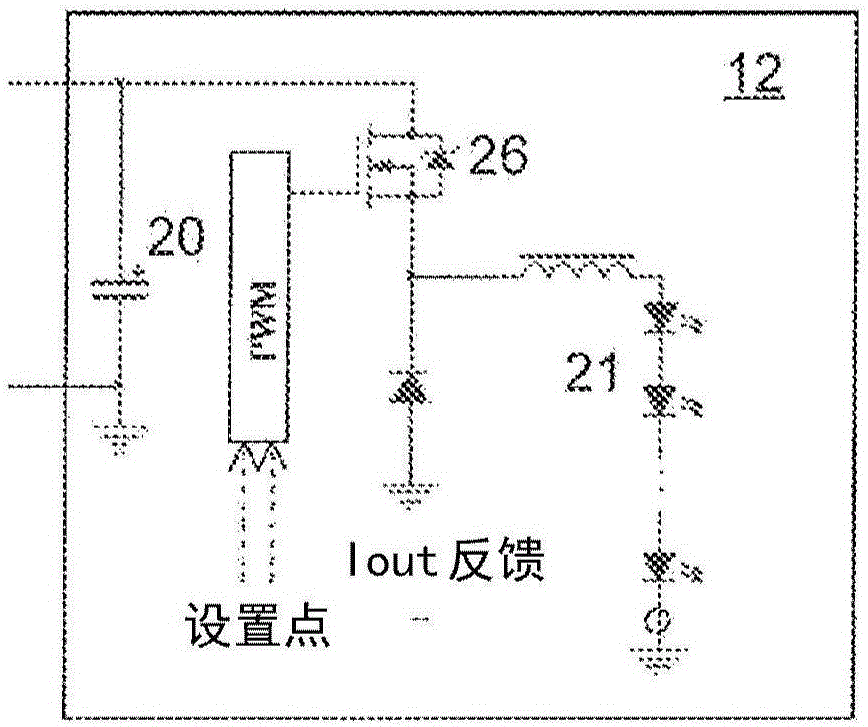

[0034] image 3 A simplified structure of a pump module of a fiber laser using a high frequency PWM (Pulse Width Modulation) method to control the pump current (buck stage) is shown. and figure 2 different, image 3 The control element 26 in the circuit works in a high-frequency switching mode (hundreds of kilohertz).

[0035] If the voltage applied to the pump diode is below a certain value that defines the threshold current that the diode produces, the diode cannot irradiate enough energy to produce dangerous levels of laser emission. We tentatively specify this safe voltage value as 20 volts, moreover, a supply voltage of the order of about 75 volts is required for normal operation of the pump module. The value 20V is determined by the total number of pumping diodes 21 connected in series as one circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com