Buton rock asphalt modified asphalt mixture heating blending manufacture technology

A technology of asphalt mixture and asphalt modification, which is applied in roads, road repairs, roads, etc., can solve the problem of not considering the ability of coarse and fine aggregates and rock asphalt to absorb asphalt, reducing the economical efficiency of Buton rock asphalt modified asphalt, and the failure to achieve To improve the adhesion and wrapping effect, the mixing process is simple and efficient, and the road performance can be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Firstly, the Buton rock asphalt is sampled, and then the sample is subjected to an extraction test, and the bitumen content of the Buton rock asphalt is 30.7%. A sieving test was carried out on the asphalt ash material obtained from the extraction test, and the test results are shown in Table 1.

[0032] Table 1 Mineral screening results after extraction of Butonite bitumen

[0033] Mesh size / mm

4.75

2.36

1.18

0.6

0.3

0.15

0.075

Passing rate / %

100

98.93

91.42

84.15

73.38

54.33

38.62

[0034] The coarse aggregate is made of diabase, and the specific screening results are shown in Table 2. The relative density of the aggregate and the ash content of the extracted Butonite asphalt was tested, and the test results are shown in Table 3.

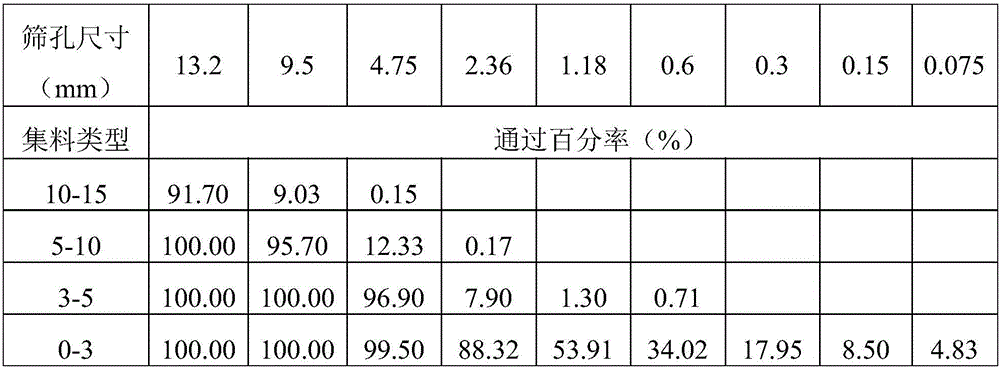

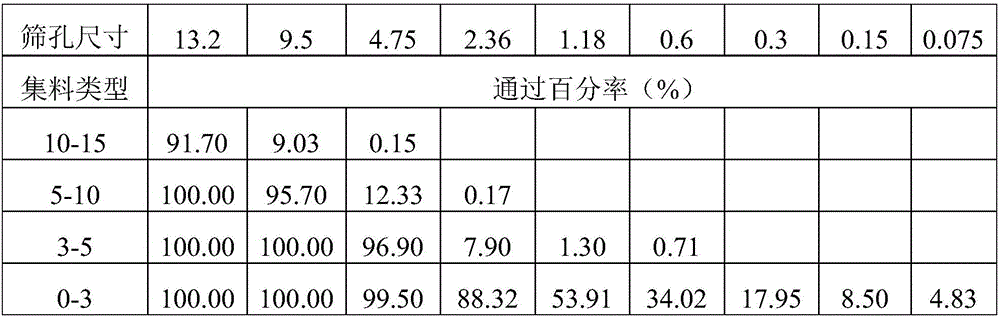

[0035] Table 2 Screening results of coarse and fine aggregates

[0036]

[0037] Table 3 Test results of relative density of aggregate and Buton rock asphalt ash

[0038] ...

Embodiment 2

[0062] Firstly, the Buton rock asphalt is sampled, and then the sample is subjected to an extraction test, and the bitumen content of the Buton rock asphalt is 30.7%. A sieving test was carried out on the asphalt ash material obtained from the extraction test, and the test results are shown in Table 6.

[0063] Table 6 Mineral screening results after extraction of Buton rock asphalt

[0064] Mesh size / mm

4.75

2.36

1.18

0.6

0.3

0.15

0.075

Passing rate / %

100

98.93

91.42

84.15

73.38

54.33

38.62

[0065] The coarse aggregate is made of diabase, and the specific screening results are shown in Table 7. The relative density of the aggregate and the ash content of the extracted Butonite asphalt was tested, and the test results are shown in Table 8.

[0066] Table 7 Screening results of coarse and fine aggregates

[0067]

[0068] Table 8 Test results of relative density of aggregate and Buton rock asphalt ash

[0069...

Embodiment 3

[0093] Indoor test example: first, the Buton rock asphalt is sampled, and then the sample is subjected to an extraction test, and the asphalt content of the Buton rock asphalt is 30.7%. A sieving test was carried out on the asphalt ash material obtained from the extraction test, and the test results are shown in Table 11.

[0094] Table 11 Mineral screening results after extraction of Buton rock asphalt

[0095] Mesh size / mm

4.75

2.36

1.18

0.6

0.3

0.15

0.075

Passing rate / %

100

98.93

91.42

84.15

73.38

54.33

38.62

[0096] The coarse aggregate is made of diabase, and the specific screening results are shown in Table 12. The relative density of the aggregate and the ash content of the extracted Butonite asphalt was tested, and the test results are shown in Table 13.

[0097] Table 12 Screening results of coarse and fine aggregates

[0098]

[0099] Table 13 Test results of relative density of aggregate and Buton ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com