A new type of external wall panel node and its construction method

An external wall panel and node technology, applied in the direction of walls, building types, buildings, etc., can solve the problems that the component nodes cannot be quickly assembled and installed, the cold and heat bridge effect is unavoidable, and the supporting system is not perfect, so as to ensure the appearance and unity. performance, shorten the construction period, and meet the effect of thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

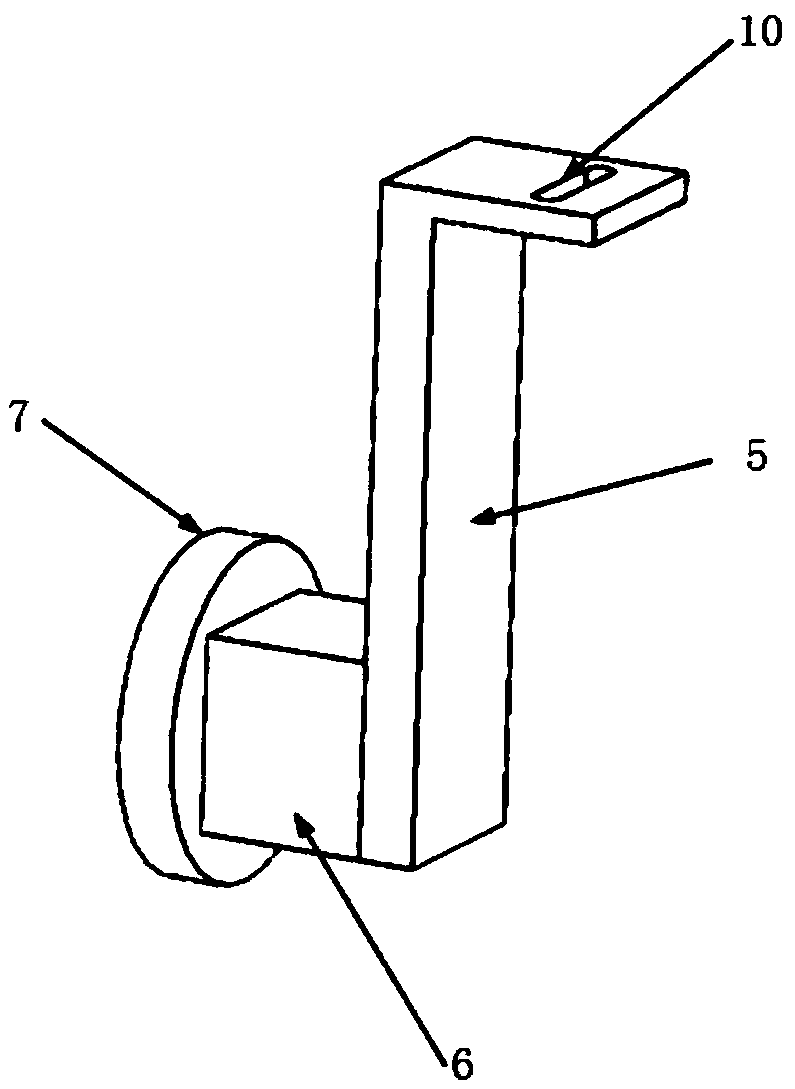

[0028] Such as figure 2 As shown, the L-shaped connector 3 includes an L-shaped connecting plate 5, a supporting square steel pipe 6 and a circular end plate 7, the L-shaped connecting plate 5 includes long and short plates perpendicular to each other, and one end of the supporting square steel pipe 6 is connected to the L-shaped The long plate of the plate 5 is connected, and one end is connected with the circular end plate 7, and the short plate of the L-shaped connecting plate 5 has an oblong hole 10.

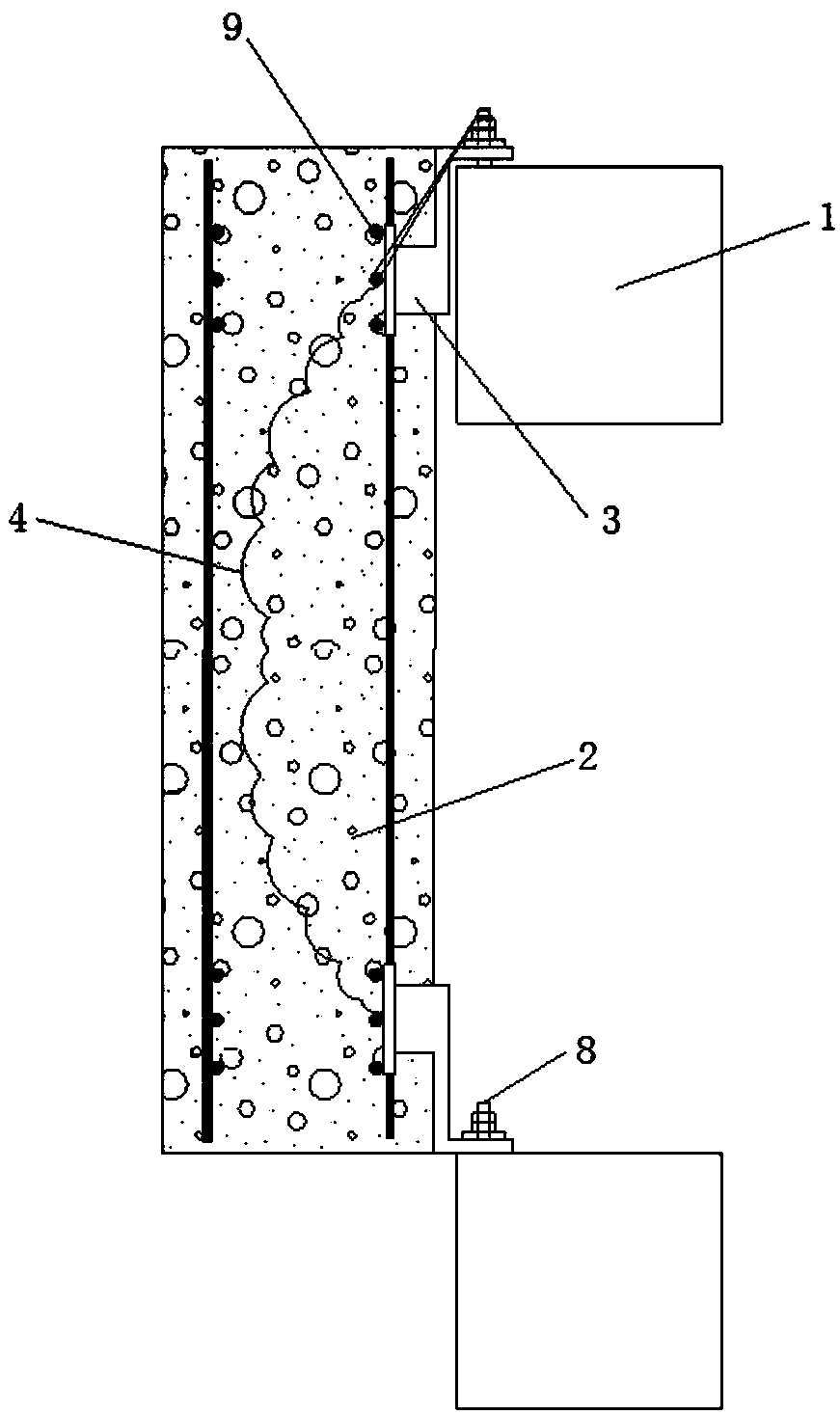

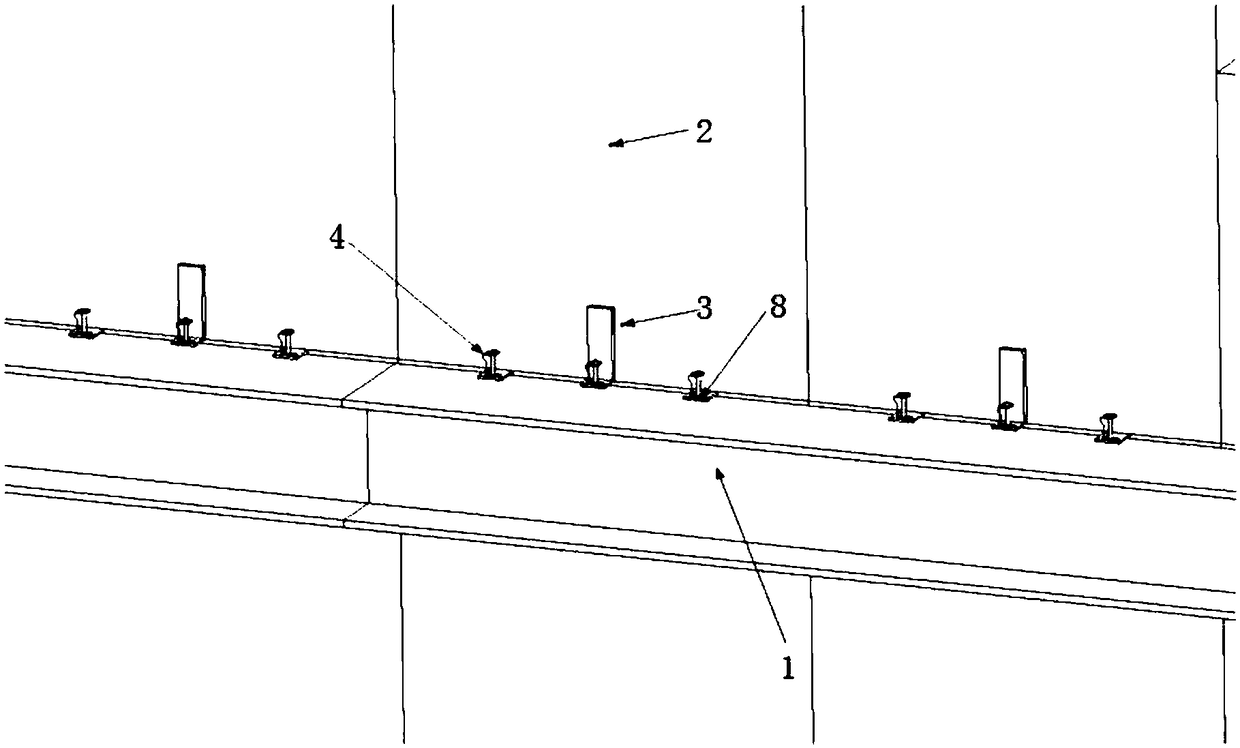

[0029] Such as figure 1 As shown, a new type of external wall panel node, including the main structural beam 1, the external wall panel 2 and the L-shaped connector 3 connecting the two, the main structural beam 1 is provided with an encrypted steel mesh 9 and a nylon strip 4, the main body Bolt rods 8 are arranged on the structural beam 1, the circular end plate 7 at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com