Ultra-high-pressure hydraulic auxiliary rock breaking TBM (Tunnel Boring Machine) cutterhead

An ultra-high pressure, cutter head technology, applied in mining equipment, earth-moving mining, tunnels, etc., can solve problems such as restricting the construction period of the project, and achieve the effect of reducing equipment energy consumption, reducing wear, and saving operation and maintenance costs and project investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

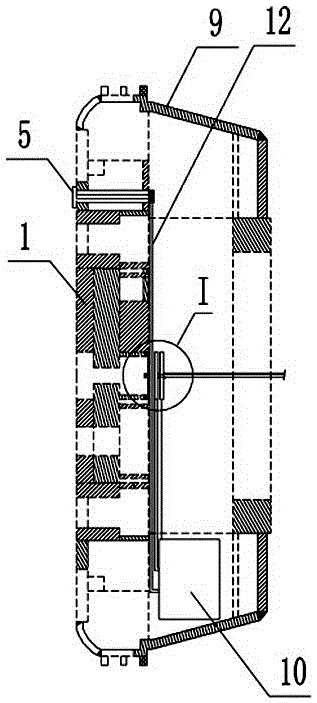

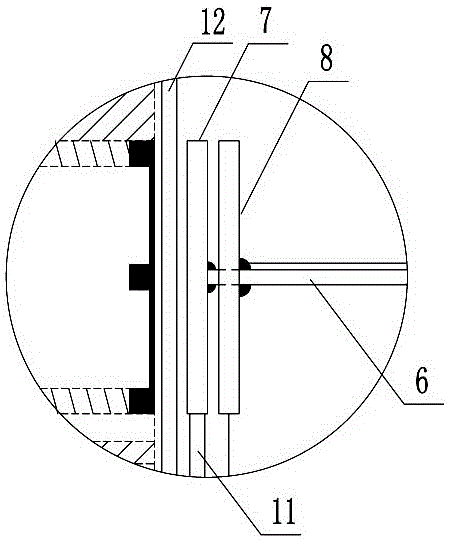

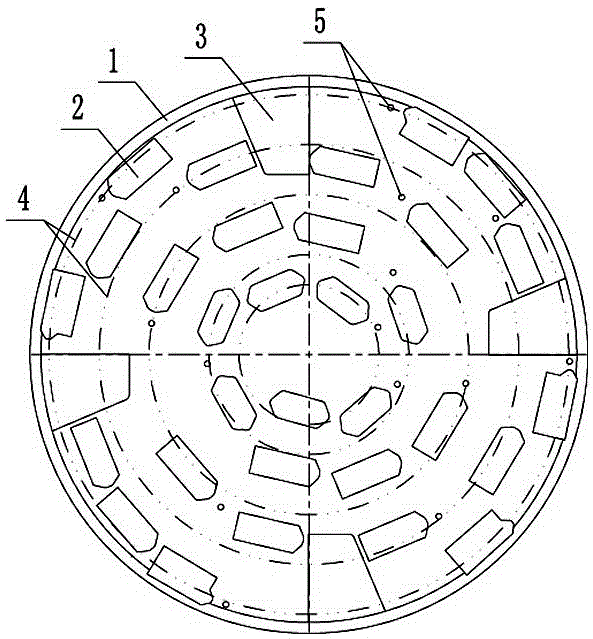

[0019] Such as Figure 1-5 As shown, the ultra-high pressure hydraulic assisted rock-breaking TBM cutter head of the present invention includes a TBM cutter head body, and the TBM cutter head body consists of a cutter head 1 and a plurality of disc-shaped The hob 2 is composed of four slag collecting buckets 3 evenly distributed on the edge of the working face of the cutter head 1; the number of running track coils 4 of the plurality of disc-shaped hobs 2 is five turns (see image 3 double-dot-dash line in the middle); a plurality of nozzles 5 are arranged on the working surface of the cutter head 1, and the plurality of nozzles 5 are respectively arranged along the running track coil 4 of the disc-shaped hob 4 or close to the running track coil 4, and arranged in the forward direction of the operation of the disc hob 2; Figure 1-2 As shown, a water supply rotary joint 7 for connecting to an external water pipe 6, a power supply communication rotary joint 8 for electrical co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com