A high-efficiency alloy joint automatic detection spheroidization device and its working method

An automatic detection and alloy technology, applied in the analysis of materials, the use of sonic/ultrasonic/infrasonic waves to analyze solids, instruments, etc., can solve problems such as large labor costs and time costs, difficulty in ensuring stability, and inability to adapt to requirements. High efficiency, reduced labor cost and time cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further clarified below in conjunction with the accompanying drawings and specific embodiments. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

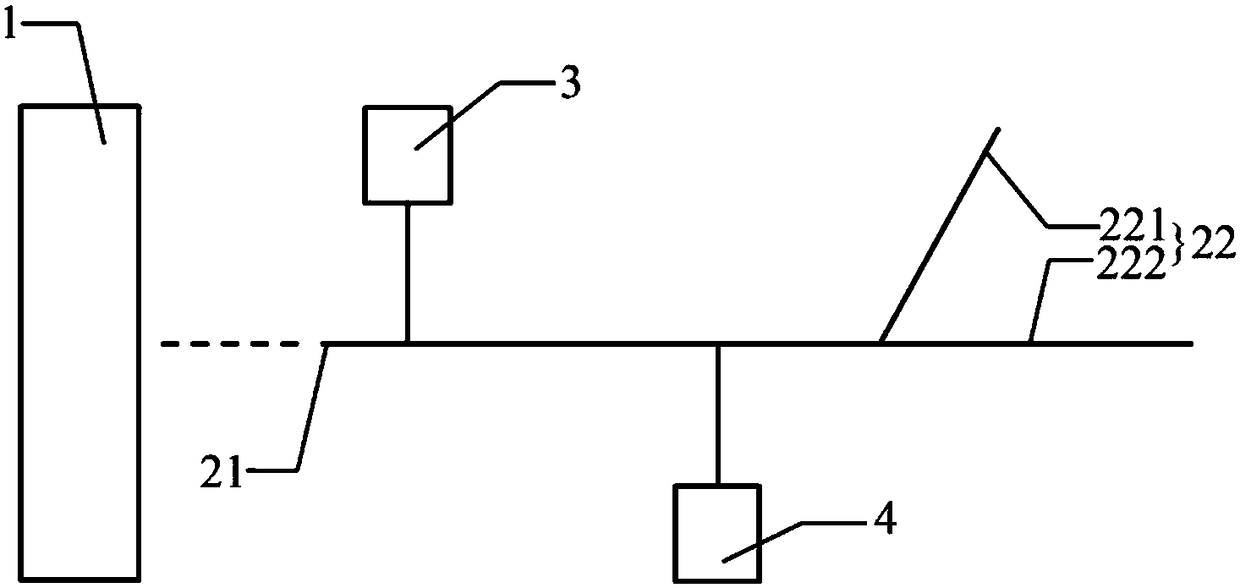

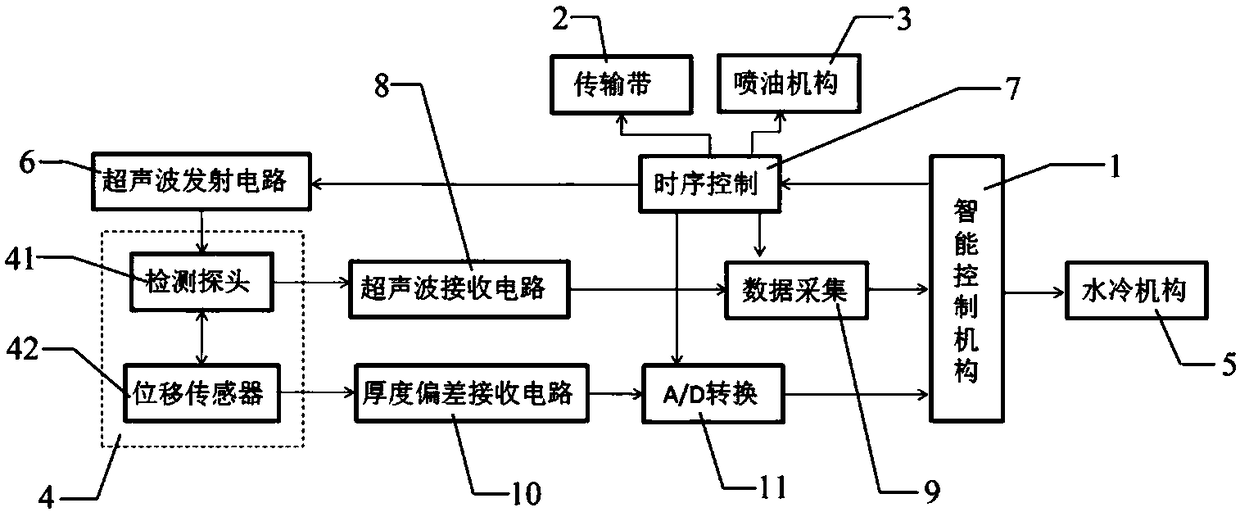

[0025] Such as Figure 1-2 The high-efficiency alloy joint automatic detection spheroidization device shown includes a transmission belt 2 electrically connected to an intelligent control mechanism 1, an oil injection mechanism 3, an ultrasonic detection mechanism 4, and a water cooling mechanism 5. The oil injection mechanism 3 is arranged on the transmission belt 2 near the input end 21, and an ultrasonic detection mechanism 4 is provided far away from the input end 21. The output end 22 of the conveyor belt 2 includes a re-detection output end 221 and a packaging output end 222.

[0026] Wherein, the intelligent control mechanism 1 includes a database and a parameter input unit....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com