Segmented comprehensive utilization mode for corn straw

A technology of corn stalks and corn, which is applied in the field of segmented comprehensive utilization of corn stalks, which can solve the problems of increasing mechanical operation costs, high energy consumption for crushing, and affecting traffic, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

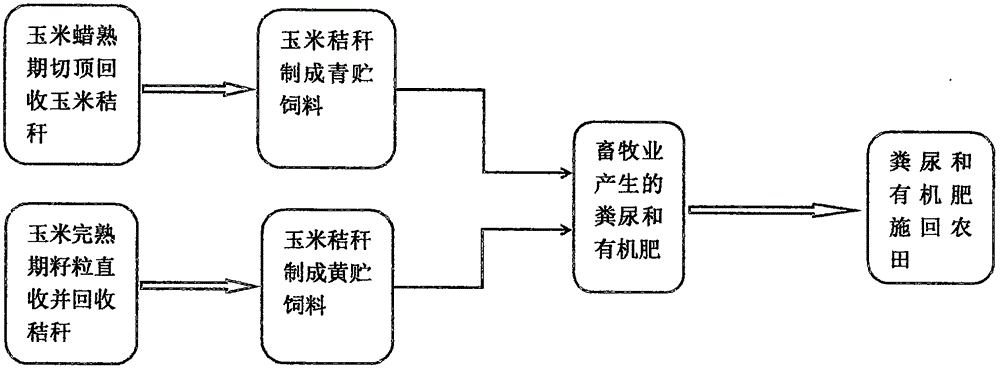

[0008] A segmented comprehensive utilization mode of corn stalks, the features of which include:

[0009] After the corn wax maturity period, cutting the plants above the corn cob means cutting the top of the corn. At this time, cutting the top of the corn can realize the windproof and lodging resistance of the corn, good ventilation of the corn field, fast dehydration speed, reduction of corn moisture, concentration of nutrients, and increase of yield. , It is conducive to the direct harvest of corn, it matures 10-15 days in advance, harvests in advance to grab the farming time, ensures better grain quality and also ensures a better sales price, increases the purchase price of grain, reduces the cost of grain drying, and prevents mildew To ensure food safety; since the corn has just passed the wax ripening period, the water content of the plant is suitable for silage fermentation, the cut corn stalks are recycled and crushed, and silage is made into silage through silage ferme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com