Processing method of fagopyrum tataricum kernels

A processing method and tartary buckwheat technology are applied in the field of tartary buckwheat rice processing, which can solve problems such as inability to eat frequently, and achieve the effects of avoiding hypotension and reducing rutin content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

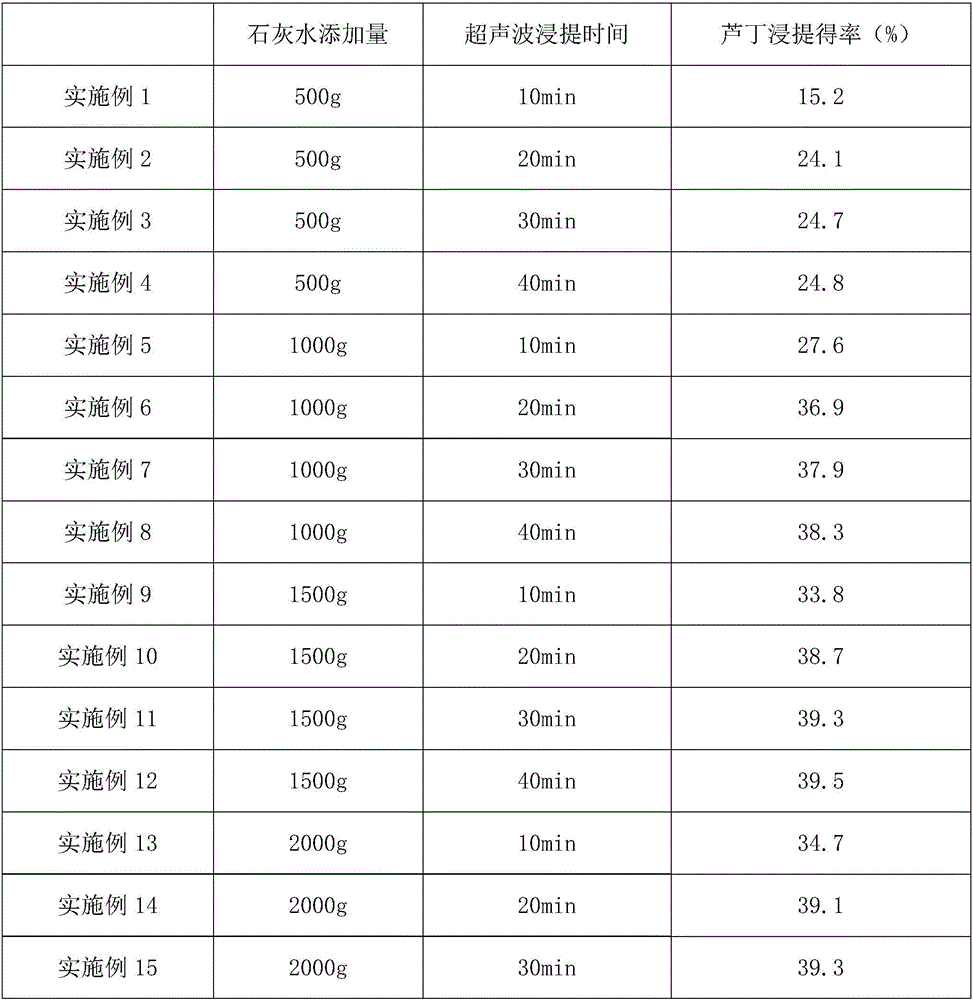

[0041] Select whole tartary buckwheat seeds and clean them, then put the cleaned tartary buckwheat seeds into clean water, soak for 10-24 hours at 10-50°C, drain the tartary buckwheat seeds after soaking, and then drain The tartary buckwheat seeds with moisture are dried in an environment with a temperature of 105° C., and the drying time is 20-60 minutes. Then, the dried tartary buckwheat seeds are divided into 16 groups, and the weight of each group of tartary buckwheat seeds is 100 g. Add different weights of lime water with a pH value of 8 to 9 to each group, perform ultrasonic constant temperature leaching at 80°C for different periods of time, and then suction filter to determine the rutin extraction yield. Refer to the percentage that the rutin powder finally obtained accounts for the total rutin content of tartary buckwheat seeds, and the reaction conditions and measurement results of each group are as shown in Table 1 below:

[0042] Table 1

[0043]

[0044]

Embodiment 2

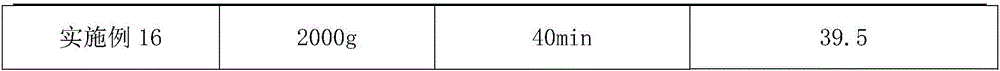

[0046] Select whole tartary buckwheat seeds and clean them, then put the cleaned tartary buckwheat seeds into clean water, soak for 10-24 hours at 10-50°C, drain the tartary buckwheat seeds after soaking, and then drain The tartary buckwheat seeds with moisture are dried in an environment with a temperature of 105° C., and the drying time is 20-60 minutes. Then, the dried tartary buckwheat seeds are divided into 16 groups, and the weight of each group of tartary buckwheat seeds is 100 g. Add different weights of lime water with a pH value of 8 to 9 in each group, suction filter after 20 minutes of ultrasonic constant temperature leaching under different temperature conditions, and measure the extraction yield of rutin. The extraction yield of rutin is Refer to the percentage that the rutin powder finally obtained accounts for the total rutin content of tartary buckwheat seeds, and the reaction conditions and measurement results of each group are shown in Table 2 below:

[0047...

Embodiment 3

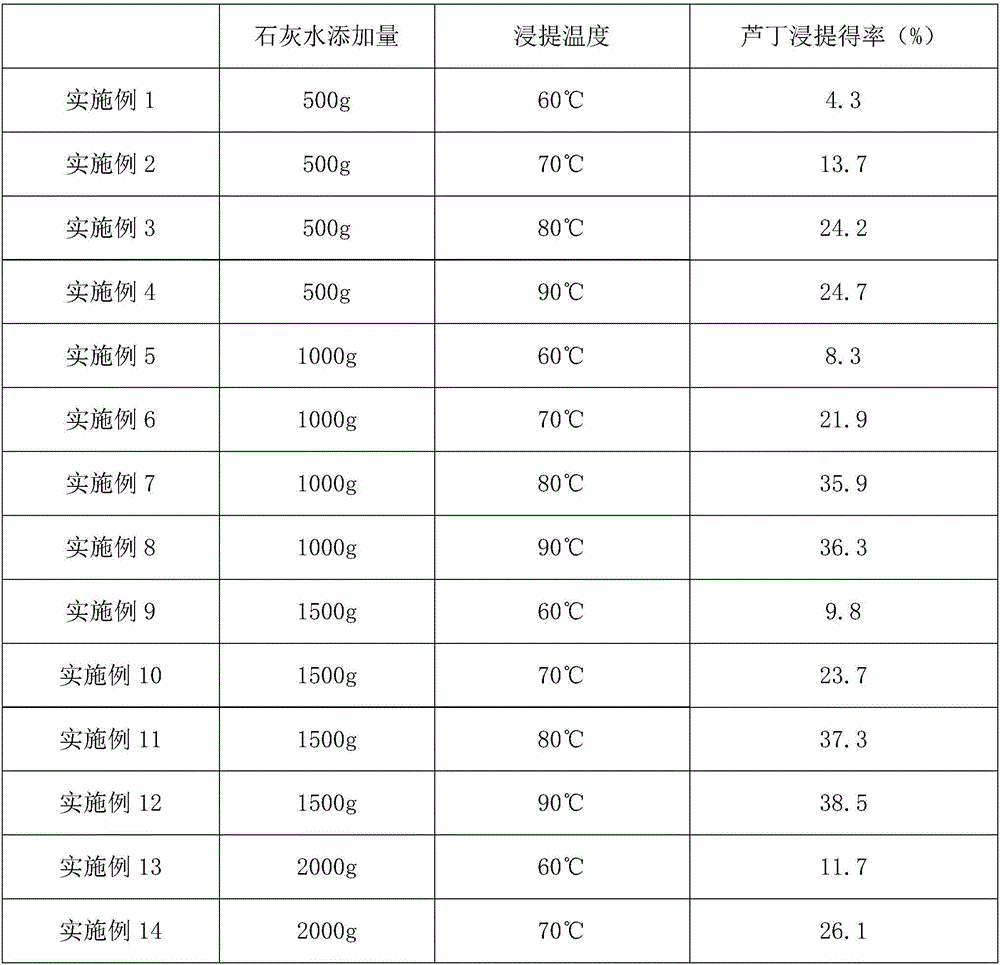

[0052] Select whole tartary buckwheat seeds and clean them, then put the cleaned tartary buckwheat seeds into clean water, soak for 10-24 hours at 10-50°C, drain the tartary buckwheat seeds after soaking, and then drain The tartary buckwheat seeds with moisture are dried in an environment with a temperature of 105° C., and the drying time is 20-60 minutes. Then, the dried tartary buckwheat seeds are divided into 16 groups, and the weight of each group of tartary buckwheat seeds is 100 g. Add 1000g of lime water with a pH value of 8 to 9 to each group, carry out ultrasonic constant temperature leaching for different times under different leaching temperature conditions, and then suction filter to measure the leaching yield of rutin. Yield refers to the percentage of rutin powder finally obtained in the total rutin content of tartary buckwheat seeds. The reaction conditions and measurement results of each group are shown in Table 3 below:

[0053] table 3

[0054]

[0055] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com